A-286 High Temperature Alloy Wire for Aerospace Engines - Oxidation & Corrosion Resistant

Discover our premium A-286 high temperature alloy wire, engineered as an iron-base superalloy (UNS S66286) for aerospace engines.

- Overview

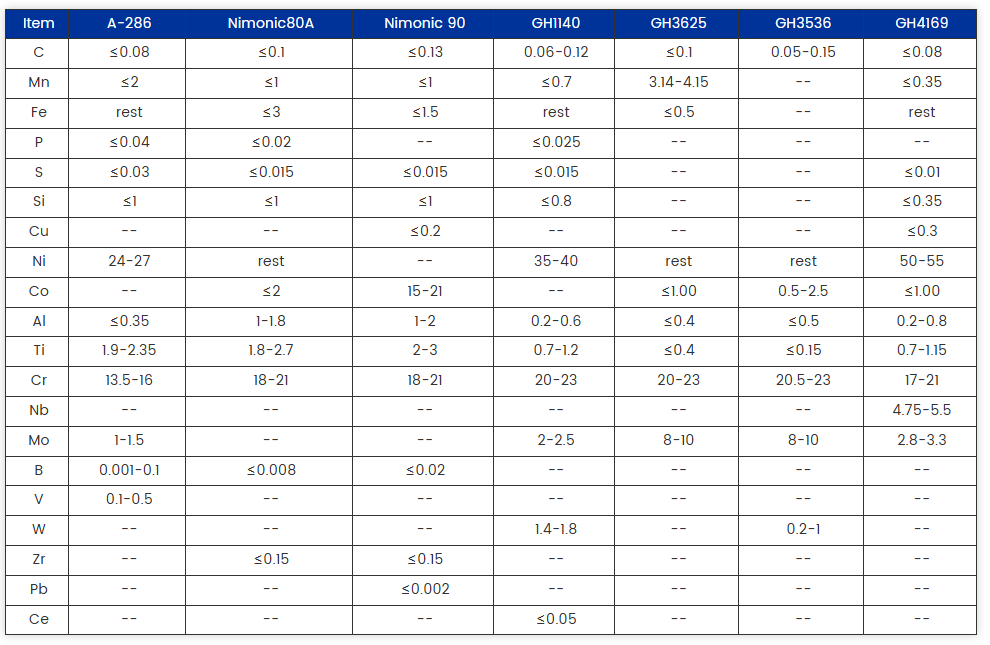

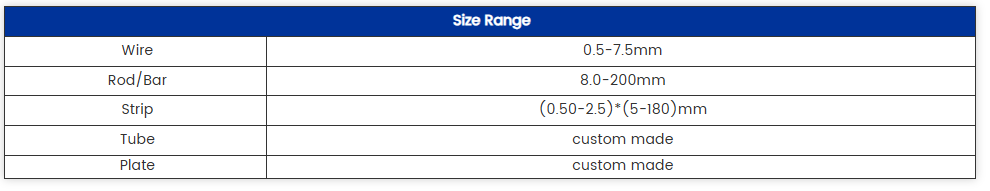

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Product Introduction Overview

A-286 High Temperature Alloy Wire: The Ultimate Superalloy for Aerospace Engines and High-Temp Performance

A-286 alloy wire stands out as a precipitation-hardening iron-nickel-chromium superalloy, compliant with AMS 5731, AMS 5732, AMS 5737, and AMS 5525 standards. Designed for superior high temperature strength and corrosion resistance in oxidative atmospheres, it excels in aerospace engine environments where thermal stresses and corrosive elements demand reliability. Unlike standard stainless steels, A-286 maintains structural integrity from cryogenic lows to elevated highs, offering enhanced ductility in notched sections and excellent weldability for complex fabrications.

Product Features

Key Features of A-286 Oxidation Resistant Alloy Wire for High-Temp Aerospace Use

- Superior High Temperature Resistance: Maintains yield strength (up to 90,000 psi) and tensile properties up to 1300°F (704°C), with short-term capability to 1500°F (816°C) – ideal for creep and stress rupture in turbine engines.

- Excellent Oxidation & Corrosion Protection: Resists scaling and pitting in jet engine atmospheres, saltwater, and acidic conditions, outperforming many nickel alloys in oxidative environments.

- Age-Hardenable Superalloy Design: Precipitation hardening process boosts hardness and fatigue resistance without compromising ductility; age-hardened for AMS-compliant performance.

- High Strength-to-Weight Ratio: Iron-base composition provides lightweight yet robust wire for aerospace fasteners, with notched rupture strength superior to competitors.

- Versatile Formability & Weldability: Available in various diameters for wire drawing, suitable for cold working and heat treatments like solution annealing at 1800°F followed by aging.

- Compliance & Certifications: Meets aerospace specs (AMS 5525 sheet/wire, ASTM A453), ensuring traceability for critical applications in propulsion systems.

Product Applications

A-286 Corrosion Resistant Wire Applications in Aerospace Engines and Beyond

- Jet Engine Components: Used in turbine blades, exhaust nozzles, and afterburner parts requiring high-temp oxidation resistance and creep strength.

- Aerospace Fasteners & Bolts: Ideal for high-strength bolts in airframes and engines, where corrosion protection under thermal cycling is essential.

- Gas Turbine & Power Generation: Superalloy wire for seals, springs, and valves in high-pressure, oxidative environments up to 704°C.

- Automotive & Industrial High-Temp Parts: Exhaust manifolds, turbocharger components, and chemical processing equipment needing stress rupture resistance.

- Cryogenic & Low-Temp Aerospace: Retains properties down to -320°F for space propulsion and structural supports.

Product FAQ

Frequently Asked Questions About A-286 High Temperature Superalloy Wire

1.What makes A-286 alloy wire better than Inconel for aerospace engines?

A-286 offers comparable high temperature strength and oxidation resistance at a lower cost as an iron-base superalloy, with superior creep properties up to 1300°F versus nickel alternatives.

2.How does A-286 handle corrosion in jet engine atmospheres?

It provides excellent resistance to oxidation and scaling in high-temp oxidative conditions, thanks to its chromium content and age-hardening, outperforming standard austenitic stainless steels.

3.What are the standard heat treatments for A-286 wire?

Solution anneal at 1800°F (982°C) for 1 hour, followed by oil quench and aging at 1325°F (718°C) for 16 hours to achieve peak strength per AMS 5731 specs.

4.Is A-286 wire suitable for welding in aerospace fabrication?

Yes, with excellent weldability using TIG or MIG processes; post-weld aging restores high strength and corrosion resistance without cracking risks.