A long-term U.S. customer, specializing in the design and manufacturing of high-performance industrial heating systems, partnered with DLX Alloy to upgrade their heating elements using our premium FeCrAl resistance wire. Facing challenges with traditional materials failing under extreme temperatures and oxidative environments, the customer required a solution that could withstand continuous operation above 1200°C while maintaining structural integrity and electrical stability. DLX Alloy provided customized high-temperature resistant FeCrAl wire 0Cr25Al5, delivering superior oxidation resistance through a protective alumina layer, extended service life, and reduced downtime—demonstrating our deep expertise in electrothermal alloys and commitment to tailored customer solutions.

An Indian power generation company successfully applied INCONEL 625 welding wire from Changzhou DLX Alloy Co., Ltd. in the welding repair and manufacturing of key components in their flue gas desulfurization (FGD) system. Facing severe acidic corrosion from SO₂, chlorides, and high-temperature wet environments, the customer adopted our high-performance INCONEL 625 (ERNiCrMo-3) welding wire for overlay welding and dissimilar metal joining. This solution significantly enhanced the corrosion resistance of absorption towers, scrubbers, and pipelines, extending equipment service life by 30% while reducing maintenance frequency and operational costs.

In the demanding world of natural gas processing, where harsh acid gases like hydrogen sulfide (H2S) and carbon dioxide (CO2) pose relentless threats to equipment integrity, one leading US energy company turned to DLX Alloy for a reliable solution. Our expertise in high-performance nickel alloys delivered Hastelloy C276 seamless tubes that not only withstood extreme corrosive environments but also ensured seamless operations. This case study highlights how DLX Alloy's unwavering commitment to product excellence and customer-centric service transformed a critical challenge into a resounding success.

In the dynamic world of industrial manufacturing, where precision welding is critical for structural integrity and longevity, Changzhou DLX Alloy Co., Ltd. has forged a robust partnership with a leading Turkish shipbuilding firm. This case highlights our expertise in delivering high-performance nickel-based welding wires, such as ERNiCrMo-3 and ERNiCrMo-4, tailored for demanding marine environments. Over three years of collaboration, we've not only met but exceeded expectations, demonstrating our unwavering commitment to product excellence and superior customer service. This partnership underscores how DLX Alloy's innovative solutions drive efficiency, reduce costs, and ensure safety in high-stakes applications.

The UAE customer, who has been working with us for more than two years, is a large oil and gas company specializing in oil drilling, gas extraction and refining processes. They needed a high-strength, corrosion-resistant material for key components of offshore drilling rigs, including valves, fasteners, and drilling equipment shafts, in order to increase equipment life and reduce maintenance costs.

The customer is a large Iranian manufacturing company, mainly producing industrial heating equipment. They needed a high performance, high temperature resistant Nichrome Wire with the following characteristics:

The customer is an enterprise engaged in the manufacture of Marine engineering equipment, and needs a corrosion-resistant, lightweight and high-strength titanium alloy for the manufacture of offshore platform structural parts. The specific requirements include:

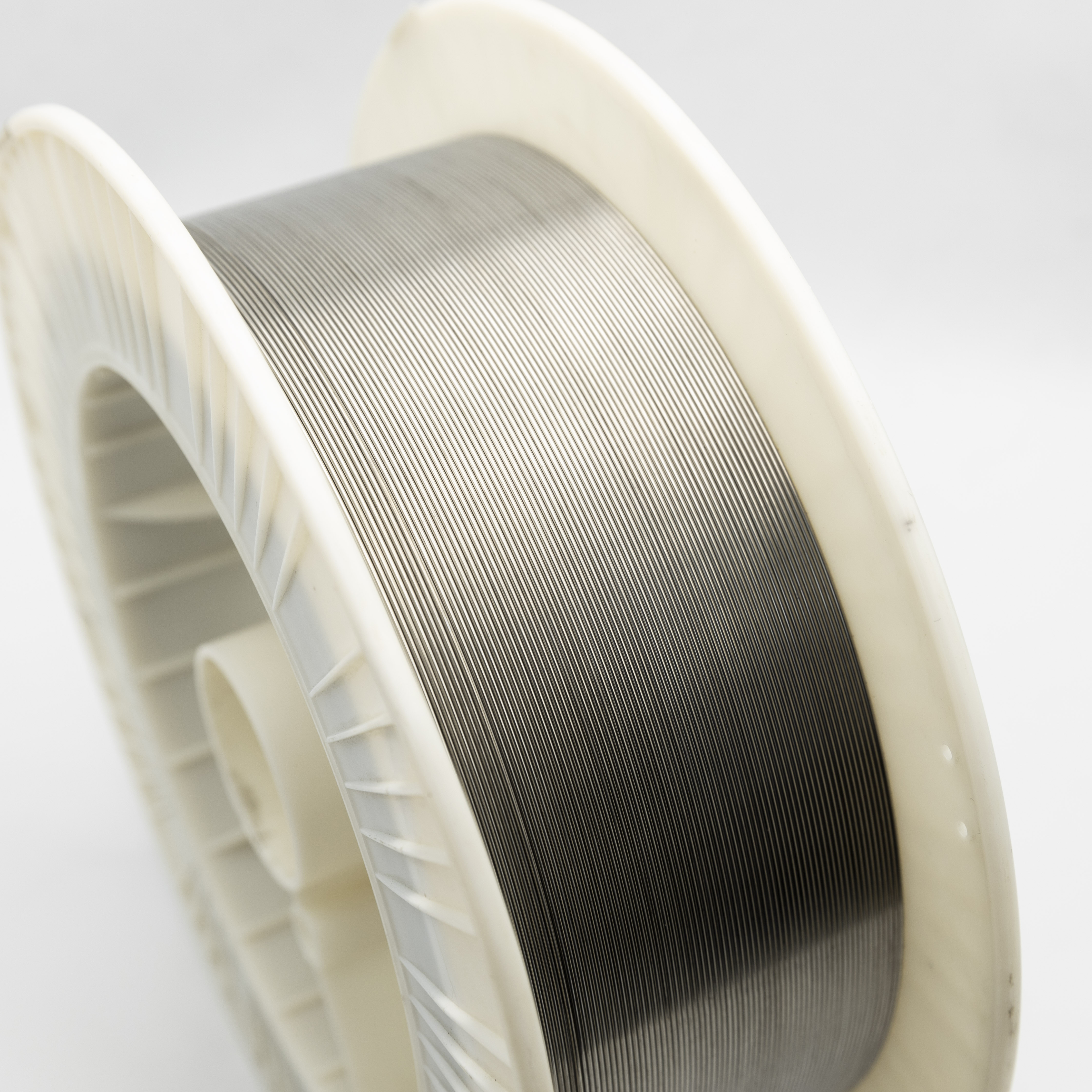

The customer is a new energy battery manufacturer, mainly producing lithium battery modules. They needed a high-purity nickel strip material for the connection of battery modules, and specific requirements included: