An Indian power generation company successfully applied INCONEL 625 welding wire from Changzhou DLX Alloy Co., Ltd. in the welding repair and manufacturing of key components in their flue gas desulfurization (FGD) system. Facing severe acidic corrosion from SO₂, chlorides, and high-temperature wet environments, the customer adopted our high-performance INCONEL 625 (ERNiCrMo-3) welding wire for overlay welding and dissimilar metal joining. This solution significantly enhanced the corrosion resistance of absorption towers, scrubbers, and pipelines, extending equipment service life by 30% while reducing maintenance frequency and operational costs.

The Indian customer is a leading thermal power enterprise with multiple large-scale coal-fired power plants. They have been cooperating with Changzhou DLX Alloy Co., Ltd. for over three years. The desulfurization systems in their plants operate under harsh conditions, frequently exposed to corrosive media such as sulfuric acid, hydrochloric acid, and fluoride ions. Traditional stainless steel or ordinary nickel-based welding materials experienced severe pitting, crevice corrosion, and stress corrosion cracking, resulting in short equipment life and high replacement costs.

✔Excellent resistance to acidic corrosion — Materials must withstand pitting, crevice corrosion, and stress corrosion in low-pH, high-chloride wet flue gas environments.

✔ Superior high-temperature performance and weldability — Welding wire needed for overlay on carbon steel/low-alloy steel bases and repair welding of Inconel 625 components, ensuring weld seams maintain consistent corrosion resistance without sensitization or cracking.

✔ Extended equipment life and reduced downtime — Achieve longer maintenance cycles and lower overall costs in high-availability power plants.

After in-depth analysis of the customer's operating conditions and corrosion data, our technical team recommended INCONEL 625 welding wire (ERNiCrMo-3) as the optimal solution. This welding wire features high nickel (≥58%), chromium, molybdenum, and niobium content, providing outstanding resistance to oxidizing and reducing acids, as well as exceptional pitting and crevice corrosion resistance.

✔ Precise matching of chemical composition and mechanical properties to ensure weld metal performance equals or exceeds the base material.

✔ Support for multiple welding processes (GTAW/TIG, GMAW/MIG, SAW), ideal for overlay welding on large desulfurization equipment and dissimilar metal joints.

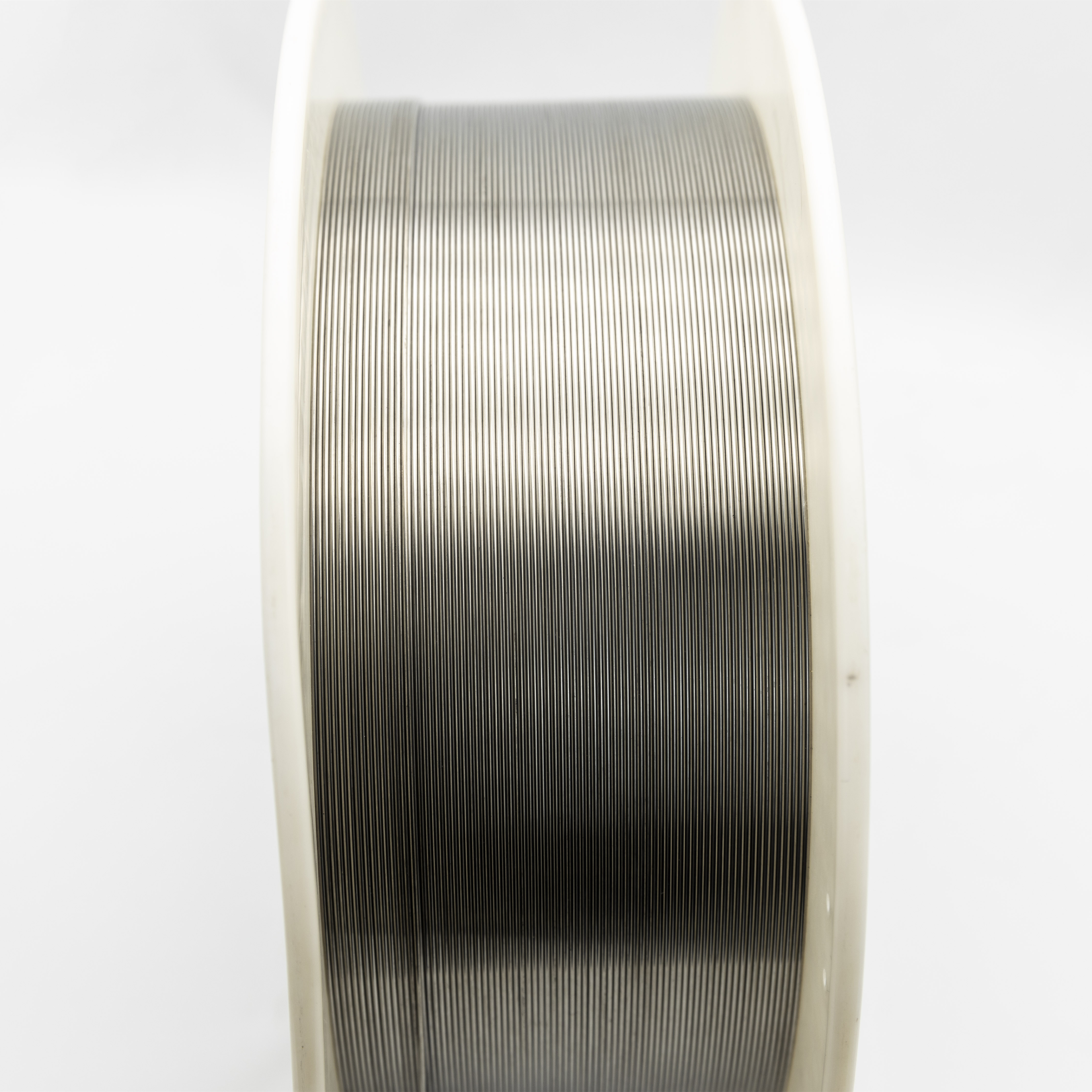

✔ Customized diameters (1.2mm, 2.4mm, 3.2mm) and packaging to meet on-site construction needs.

✔ Pre-delivery welding process guidance and parameter optimization to prevent hot cracking and ensure weld quality.

As a professional nickel alloy manufacturer with over 20 years of experience, DLX Alloy possesses deep expertise in Inconel series products and offers full-process technical support from material selection to application.

✔ Rapid delivery → First batch of 800kg INCONEL 625 welding wire in three specifications delivered within 18 days.

✔ Full technical support → Our engineers provided remote and on-site welding guidance, including process qualification (WPS/PQR) and defect prevention measures.

✔ Quality assurance → Every coil undergoes strict chemical composition, mechanical property, and corrosion testing, with full EN 10204 3.1 certification.

✔ After-sales tracking → Regular follow-up on application results and quick response to customer feedback, demonstrating DLX Alloy's commitment to long-term partnerships.

After adopting DLX Alloy's INCONEL 625 welding wire:

✔ Equipment life increased by 30%, with absorption tower and pipeline weld zones showing no significant corrosion after 18 months of operation.

✔ Corrosion resistance improved dramatically, effectively resisting pitting and stress corrosion cracking in chloride-rich environments.

✔ Maintenance costs reduced by over 25%, with significantly lower downtime and replacement frequency. The customer highly praised the stable quality of DLX Alloy's INCONEL 625 welding wire and our professional service, expressing intent to expand its use to other units' desulfurization systems and wet scrubbers.

Changzhou DLX Alloy Co., Ltd. specializes in the R&D and production of high-performance nickel alloys, including Inconel, Hastelloy, Monel, and more. We provide customized solutions for extreme corrosion environments in power, chemical, and marine engineering sectors.

For inquiries about INCONEL 625 welding wire or other alloy products, please contact us—we look forward to serving you!