In the dynamic world of industrial manufacturing, where precision welding is critical for structural integrity and longevity, Changzhou DLX Alloy Co., Ltd. has forged a robust partnership with a leading Turkish shipbuilding firm. This case highlights our expertise in delivering high-performance nickel-based welding wires, such as ERNiCrMo-3 and ERNiCrMo-4, tailored for demanding marine environments. Over three years of collaboration, we've not only met but exceeded expectations, demonstrating our unwavering commitment to product excellence and superior customer service. This partnership underscores how DLX Alloy's innovative solutions drive efficiency, reduce costs, and ensure safety in high-stakes applications.

Our Turkish partner, a prominent shipyard in Istanbul specializing in offshore vessels and oil rig components, has been at the forefront of Turkey's maritime industry for over two decades. With a focus on constructing corrosion-prone structures exposed to harsh seawater and chemical conditions, the company faced increasing demands for reliable welding materials that could withstand extreme environments without compromising weld quality. As a key player in the region's growing energy sector, they sought a dependable supplier to support their expansion into international projects, emphasizing long-term reliability and technical collaboration.

The customer required welding wires that addressed several critical challenges in their shipbuilding operations:

These needs were amplified by the need for a partner who could provide not just products, but ongoing technical support and rapid response times to align with tight project deadlines.

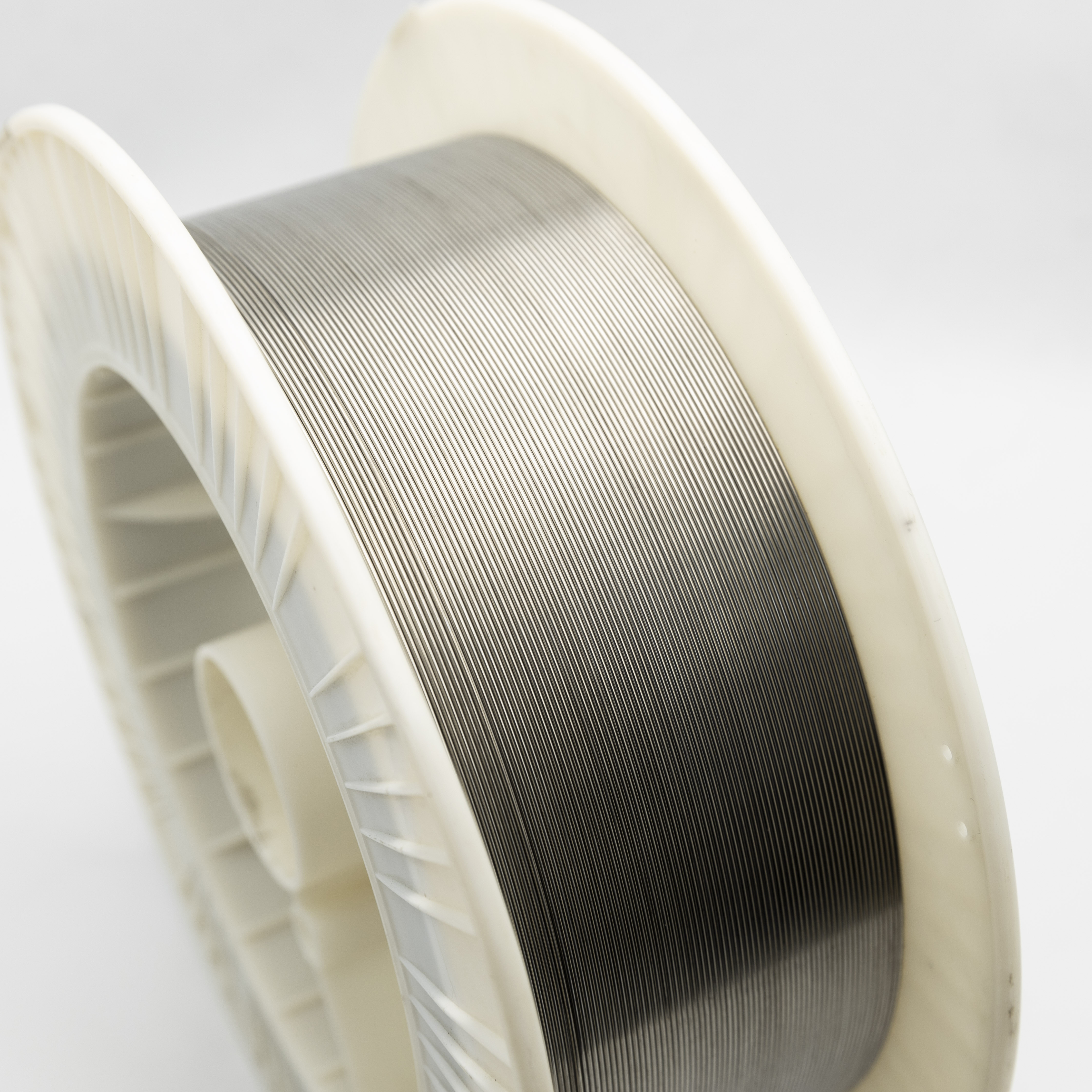

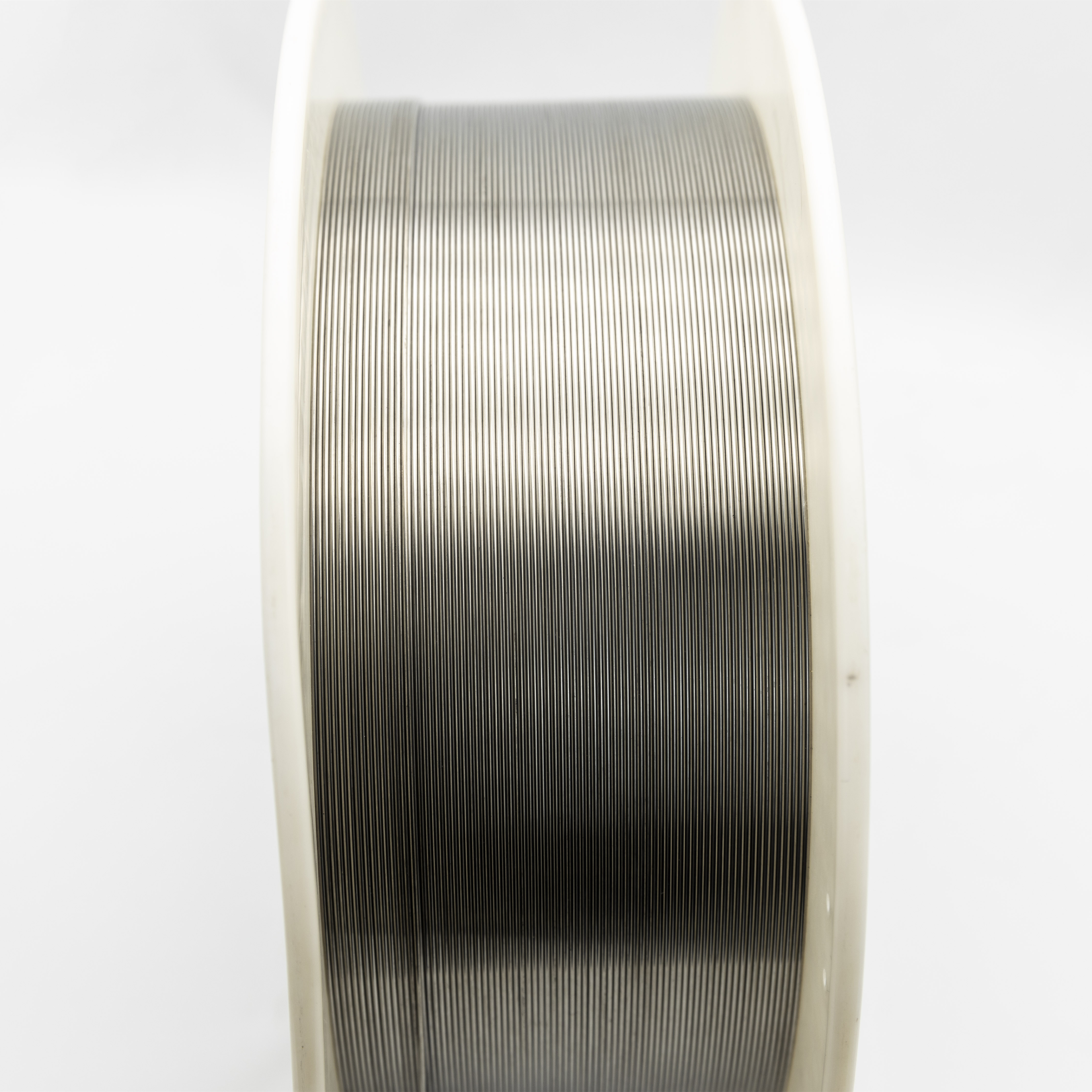

At DLX Alloy, our deep expertise in nickel-based alloys—honed through years of R&D and production—enabled us to deliver a customized solution centered on our premium ERNiCrMo-4 (C-276) welding wire. Known for its exceptional resistance to pitting, crevice corrosion, and stress-corrosion cracking, this wire offers high-temperature strength up to 1000°C and seamless integration in dissimilar metal welding.

We collaborated closely with the customer's engineering team to:

This tailored approach not only met technical specifications but also showcased our professionalism in turning complex requirements into reliable, high-performance outcomes.

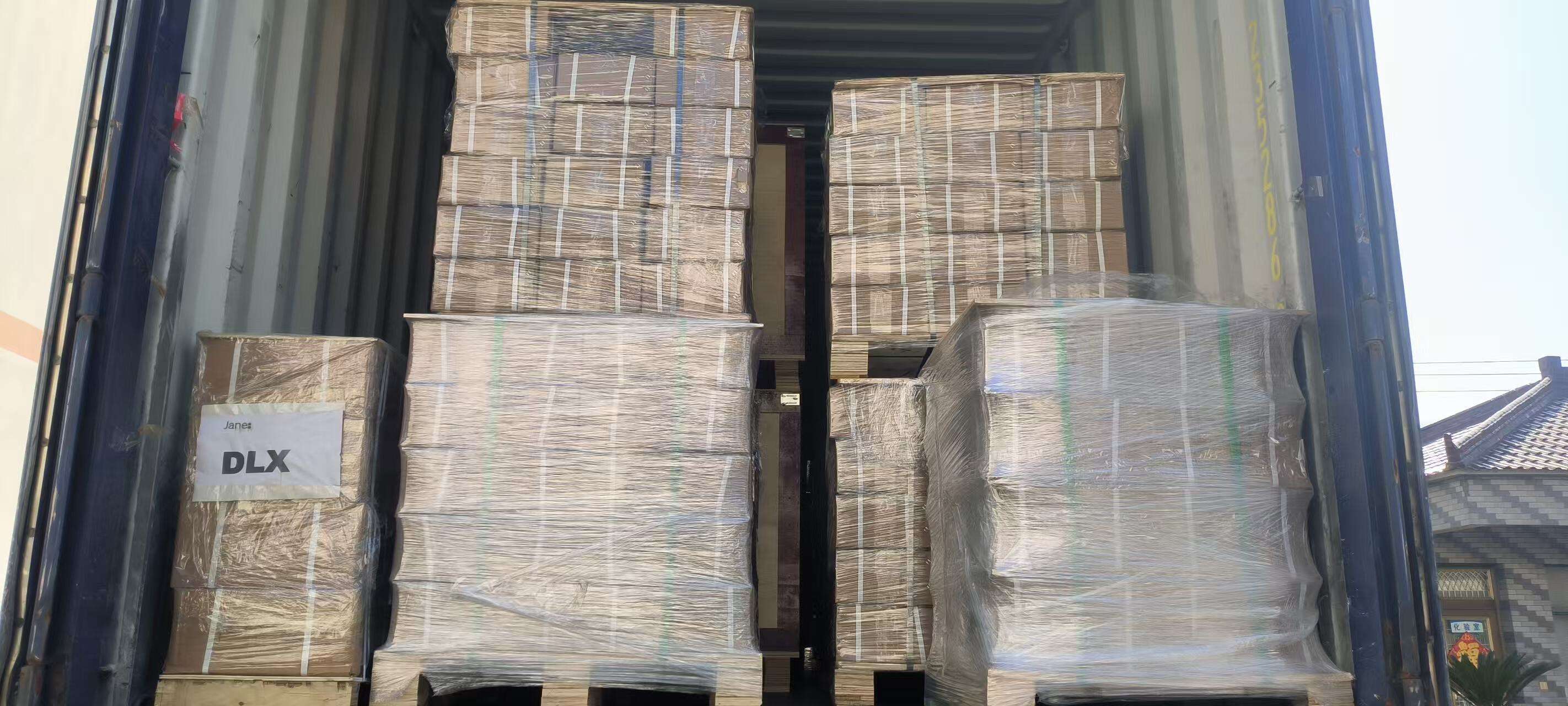

True to our reputation for excellence in customer service, DLX Alloy ensured seamless logistics from order to delivery. The initial trial batch of 1,000 kg—comprising multiple spool sizes—was dispatched within 15 days of confirmation, arriving via secure air freight to Istanbul. Subsequent orders for ongoing projects have maintained this efficiency, with lead times averaging under 20 days and real-time tracking provided through our dedicated client portal.

Our service extended beyond delivery: A multilingual technical advisor was assigned to the account, offering virtual consultations, on-site training for welding technicians, and 24/7 support for any quality queries. This proactive engagement fostered trust, resulting in a 100% on-time delivery rate and zero reported issues over the partnership's duration.

Integration of DLX Alloy's nickel-based welding wires into the customer's shipbuilding processes yielded transformative results. Post-implementation assessments revealed:

The customer has since expanded orders by 150%, citing our product's reliability and our team's responsiveness as key to their success. This long-term cooperation exemplifies DLX Alloy's dedication to innovation, quality, and partnership—empowering clients to achieve superior results in the most challenging environments. We look forward to many more years of mutual growth.