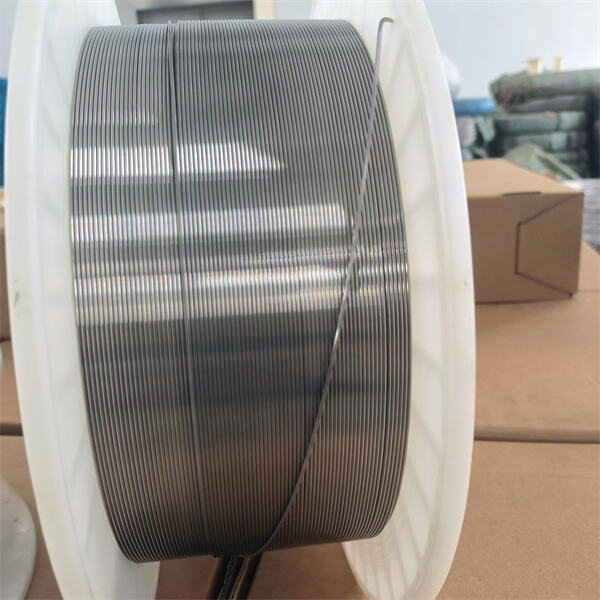

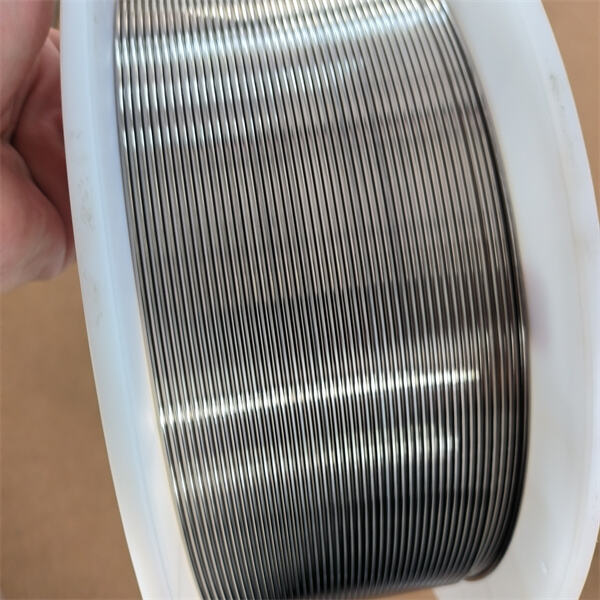

When it comes to welding projects, understanding the fundamentals of MIG wire is vital to achieving effective results. One of the most important tools for welding is DLX mig wire. It is used to keep metal components together by melting and integrating them.

Also known as welding wire, mig wire. It is a thin metal wire that fits into a welding gun. The DLX mig wire produces an electric arc that liquefies and fuses together metal pieces. Filler metal, which comes in various types and sizes, is used to make the wire. MIG wires are commonly made of aluminum, stainless steel, and carbon steel.

For instance, if welding stainless steel you need stainless steel MIG wire. Choosing the right wire allows you to make consistent, clean, and strong welds. Consider the type of metal you’re welding when selecting DLX incoloy bar.

The best way to keep MIG wire is in a dry place that is away from water and sun. How to Maintain DLX monel wire for Efficient Welding Just be careful to keep the wire dry and clean, as dirt, moisture and the like can impair the functioning of the wire.

Adjust your welding machine settings according to the wire you are using. Weld in a smooth and even manner while you try to keep your hand steady. However, if interested in making high quality welds with DLX mig wire, ensure the type and size of the wire you use matches the metal you are welding. Prior to welding, clean the metal surfaces to ensure good bond strength.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.