There is a kind of metal can be used in the world, what name is DLX 0cr21al6nb. It is composed of several parts which make it unique kinds of tools and uses. So, let’s explore the interesting metal together!

Then, what is 0cr21al6nb? The metal is in fact a blend of elements. We call this mix an alloy. In the instance of 0cr21al6nb, it is essentially composed of chromium, aluminium and niobida. These Hastelloy alloy combine to harden metal and make it useful for a myriad of applications.

0cr21al6nb has some neat properties which make it useful for a huge variety of tasks. For another, it can withstand high temperatures, so it is often used in environments where it does get really hot: in ovens and heaters, for example. It doesn’t wear out easily because this metal is also rust resistant. This is what makes it an excellent choice for outdoor structures or tools that are outdoors.

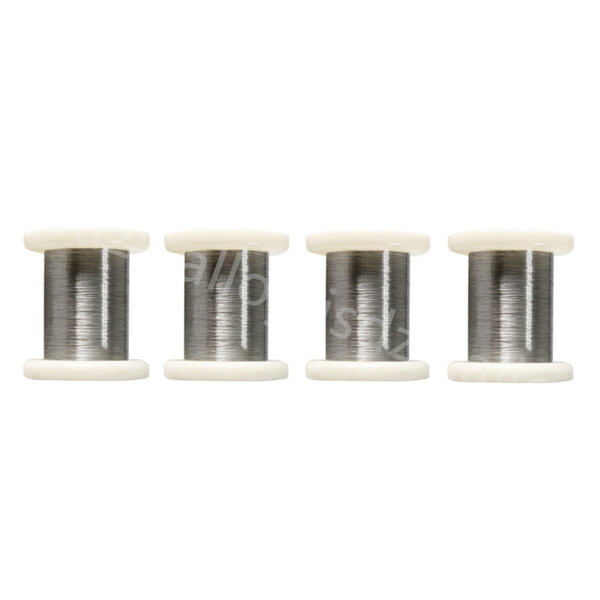

Because, in plant, 0cr21al6nb is very important to a variety of products! It is used to create electrical heating elements for stuff like ovens, toasters and hair dryers, for example. These nichrome alloy wire work safely and well, since they can handle high heat.

0cr21al6nb is unique when evaluating other alloys to choose the best material for the job. One common comparison is the contrast with kanthal, another metal commonly used to heat. The two alloys are both useful as heating elements, but DLX 0cr21al6nb is better at not rusting, so it’s a good choice when there’s water or chemicals nearby.

In case you ever at DLX 0cr21al6nb, here are some results you might want to keep in mind. First off, you’ll want to handle that metal carefully since it’s delicate. Never do this without safety gear, particularly gloves and goggles, to protect yourself! Finally, consider the fact that expansion alloy can resist high temperatures so you might need to protect yourself from burns and other injuries.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.