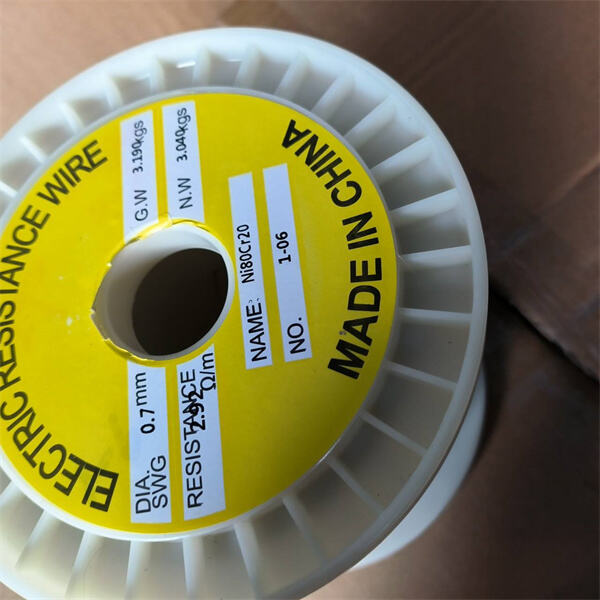

And nichrome resistance wire is a unique type of wire used in a variety of different applications ranging from heaters in appliances and temperature controlling systems. This wire is lightweight, strong, high heat (does not melt or break easily). So, here are more things that you need to know about nichrome wire resistance wire.

Resistance heating wire is made strong and nichrome is no exception. It can take quite a bit of heat without being injured. That makes it great for heaters in devices like toasters, ovens and hair dryers. Nichrome wire gets very hot, but it won’t break or wear out. That’s part of why it is the go-to for items that are meant to get hot and stay hot for an extended period of time.

Nichrome resistance wire can also be quite beneficial. It can be molded into various shapes to fit various types of heaters. Nichrome alloy wire can be shaped into any design for use in a heater coil for a stove or a toaster in straight lines. This adaptability is one of the main reasons why companies with appliances that require such heating components keep repeating their orders with this heating part manufacturer.

Many household devices require temperature control, such as ovens and water heaters. In these appliances nichrome resistance wire helps control the temperature. An electric current passes through the nichrome wire, and that generates heat in a way that can be used to regulate temperature. This allows your food to cook just right or your water to stay hot for a nice, relaxing bath.

And when it comes to making your appliances work well and avoid eating energy, efficiency is key. Nichrome resistance wire is an assist, because it heats up quickly, and then stays hot for a long time. t is environmentally friendly and also saves you money on your electricity bill.

So, Nichrome resistance wire is used not just in home digunakan but in industries too. Its applications include heaters, furnaces, and apparatus where precise temperature regulation is required. Due to the strength and reliability of resistance nichrome wire, it is an important part in many industries in which heating is particularly essential.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.