By definition, DLX Incoloy 925 is a high-strength, high-toughness metal alloy. It is used in areas with major heat or solid chemicals. We are going to explore why Incoloy Alloy is the most appropriate metal for machines used in the oil and gas industry and other factories.

DLX Incoloy 925 can withstand milli-degrees Celsius without sandals. This makes it perfect for places that get super hot, like factories or power plants. It is also quite good in resisting rust. Hastelloy Alloy certainly won’t break down easily. This matters for machines that are supposed to be long-lasting.

Incoloy 925 is also excellent at resisting damage from aggressive chemicals. Thus, it's ideal for high-chemical like lab, chemical plant environments. Rest assured, your Inconel Alloy machines will always remain safe even in extreme locations.

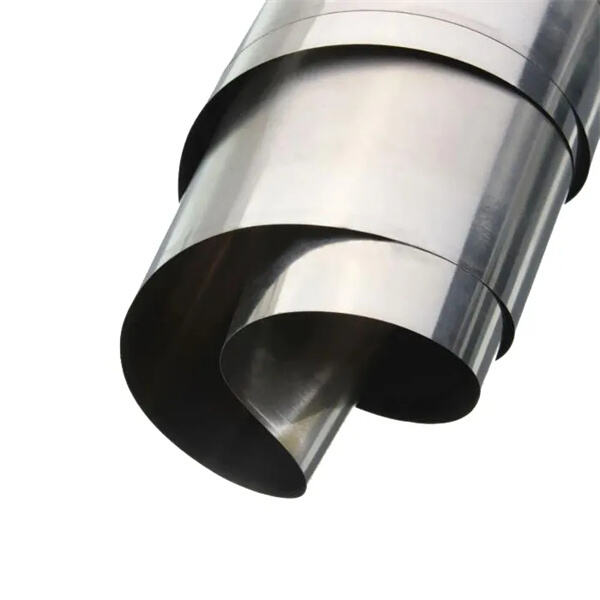

Incoloy 925 is simple to work with. Its readily weldable and fordable, so that it is available in various shapes and sizes without much struggle. This is very good for special parts or machines that need to fit within a specific size. With Incoloy 925 you simply make the parts you need.

Incoloy 925 is the ultimate in strength and toughness. It is quite powerful and can withstand significant use without incurring damage. It is ideal for busy factories where machines must operate hard during the day. DLX Incoloy 925 is a trusted alloy that will ensure the longevity of your machines.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.