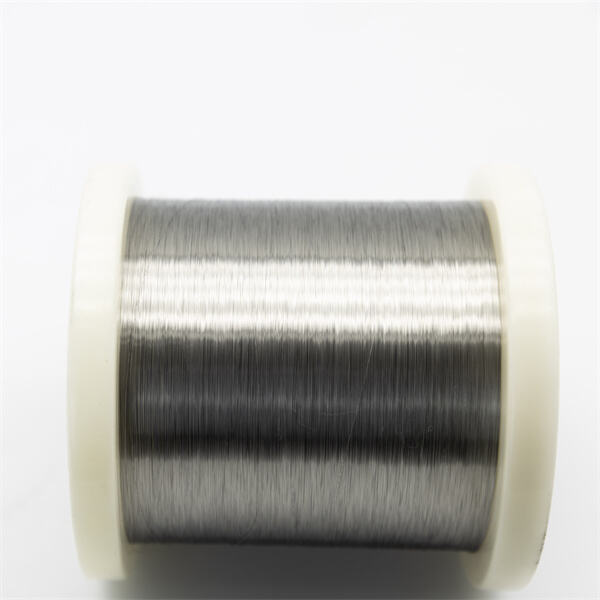

0cr21al6 is a kind of material used in industry with high temperature, the heating wire is used in various machines and the other can be made to order. This stuff has particular properties that make it good for heating things. What makes 0cr21al6 special and how to use it.

0cr21al6 is an alloy which means it is composed of more than one metal, chrome and aluminum. These precision alloy impart special properties to the alloy, including the fact that it is an excellent conductor not only of electricity but also of resistance to heat and rust. This means 0cr21al6 is suitable for use in places where things get really hot, and where other materials would not be useful.

0cr21al6 is one of the mostly used in heating systems in industrial. These are systems that heat things — ovens, machines. The DLX expansion alloys in some parts that get hot because you can heat it to like, a ridiculous temperature, without melting or breaking. That's why it's a good material for heating at factories.

0cr21al6 is also very durable so it can serve for long time without replacing. This is crucial in a factory, because if the machines stop, it can be very expensive. With the aid of nichrome alloy wire, businesses are able to ensure their machines will run smoothly for long periods of time.

Another significant property of 0cr21al6 is the resistance of corrode. Rust is what you get when metal degrades from the effects of water or chemicals. BECAUSE DLX 0cr21al6 is immune to rust it can be used in a wide variety of settings without the need for additional protection.

There are many advantages in using of DLX elastomeric alloy in hot areas. It’s highly efficient, so it can get hot fast without using a lot of energy. This saves companies money on heating. It has the ability to be formed into multiple shapes and sizes, and is therefore appropriate to being used in various heating applications.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.