What is elastomeric alloys?--it is soft strong metals that behaves like rubber: they can easily bend or stretch like rubber. These cool materials are shaking up how we manufacture and use things across a wide range of industries. The same holds true incoloy alloy — a class of material that is disrupting traditional product manufacturing. They are constructed from a combination of metal and rubber that provides specific properties. We refer to them as "alloys" because they are composed of two or more different materials.

There are many advantages of elastomeric alloys in various jobs. One major advantage is their adaptability. These polymers are like rubber: they can bend and stretch and yet not break, making them excellent for making items such as hoses and for gaskets and seals. Moreover, hastelloy alloy are also very strong, so they can last even longer without wear. They are well-suited for things such as equipment and machines.

Elastomeric alloys are extremely practical for product design. By this method they can be formed into almost any shape, meaning they can be utilized for all sorts of products. High temperature alloy are being used in ways you wouldn’t believe from toys to car parts. Because of this, designers looking to make new and strong products often opt to use these specific features.

One of the most notable ways elastomeric alloys are revolutionizing the manufacturing world is by enhancing flexibility and strength. Elastomeric alloys can bend, stretch and not break, unlike ordinary materials. Those are great for products that need to move, like shoes and clothes. Precision alloy are also very robust, which means they can withstand considerable usage without fatigue. This makes them suitable for products designed for long life.

New ideas keep popping up in the fecral alloy world. Scientists and engineers are constantly looking for ways to enhance these super substances further and to exploit them in new applications. One pretty cool novel idea is the formation of self-healing materials. If damaged, these materials have the ability to repair themselves, potentially revolutionizing manufacturing in the coming years.

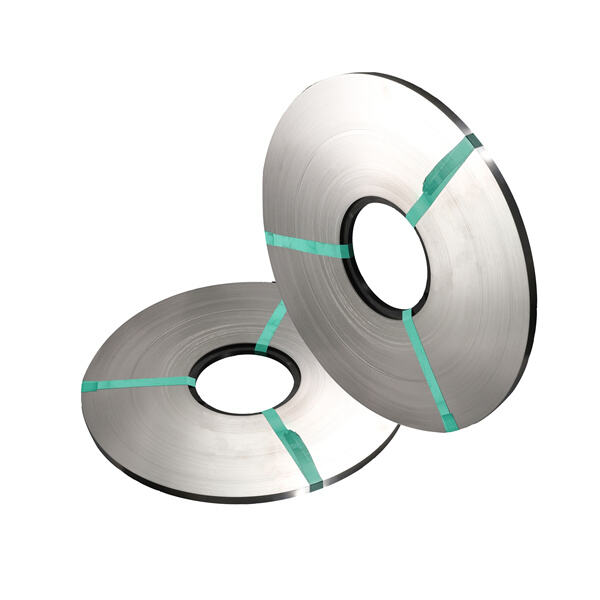

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.