Useful and Necessary Product – Thermocouple extension cables are necessary and useful products, which can make the thermocouple sensors measure the temperature reaching a long distance. Thermocouples are devices that can measure how hot or cold something is, and are used in a range of industries to ensure things are, quite literally, the right temperature. At other times, the inconel 600 welding wire by itself cannot reach to our measuring location for measuring temperature. That’s where an extension cable comes in handy!

The most common reason for using a thermocouple extension cable is to assist the measurement sensor at reaching tight locations. These DLX sensors are frequently placed in locations that can be difficult or unsafe for people to access. With an extension cable you can locate the sensor where it needs to be, and the remainder of the thermocouple somewhere convenient. This protects everyone, maintains all involved safe and ensures that people still get necessary temperature readings.

Re: It is important to be accurate when measuring temperature. If a inconel 718 welding wire sensor is in the wrong place, or if something is messing up the signal, the temperature readings can be inaccurate. Extensions cords help to make sure that the sensor is properly positioned where it can correctly measure the temperature. It has a lot of useful applications in a lot of industries, such as the food industry, where “knowing the right temperature” can be the difference between safe food and food that could sicken people.

Keeping a watch on the temperature from a remote location means controlling it from a far distance. This other person might even be in another room, building, or city. Thermocouple extension cables simplifies this, allowing the sensor to be located wherever required, even a great distance away. This ease creates a level of vigilance among companies to monitor for temperatures and ensure everything appears to be going well.

Most industries, such as agriculture or manufacturing, require high-quality heating and cooling. Thermocouple sensors are commonly used to determine if these systems are in good working order, and extension cables to these sensors help them be effectively positioned. Better monitoring and control of heating and cooling systems can be achieved employing a DLX monel 400 welding wire and save a company’s bank account from a number of potential problems.

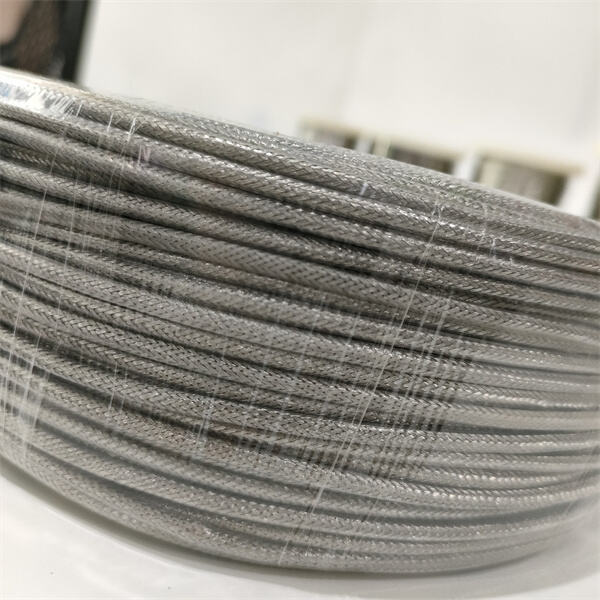

DLX thermocouple extension cables are built to last and to offer reliable connection for a variety of thermocouple links. An extension cable can help ensure that your thermocouple sensor is doing what you want, whether you're measuring the temperature of food in a restaurant kitchen or confirming the heat in a factory. Mechanical Strength When you need to make sure your sensor remains solidly connected to your measuring device, and you can trust the temperature reading you want to choose the right cable, and permanently leave it in place!"); These pure nickel welding wire are extremely durable and provide a strong connection from the sensor to the measuring device.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.