Special type T thermocouple wire. It matters for lots of things in the world, from whether our food is cooked properly to whether machines function correctly. What we are going to learn?

Type T thermocouple wire consists of two different metals which are bonded together. When these metals are heated to different temperatures, they generate a small electric current. By measuring how “hot” or “cold” something is in this way, we can find out what its temperature is.

Type T thermocouple wire is a excellent way to measure a lot of different temperatures accurately. It is also very durable and can withstand harsh environments over a lengthy time. Which makes the Thermocouple Series ideal for a variety of applications, from cooking to factory use.

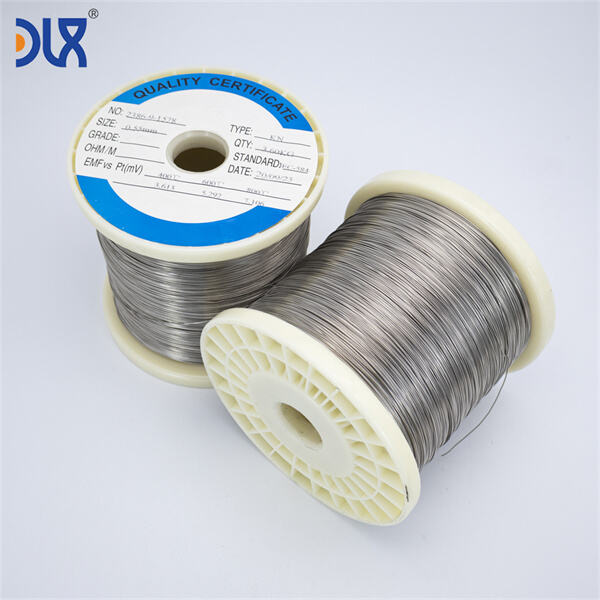

When selecting Type T thermocouple wire for your project consider elements like the temperature range you’ll be working with and the location where the wire will be used. You probably also want to think about how much the wire needs to be accurate and strong. DLX supplies many types of Type T thermocouple wire Products.

There are some characteristics of type T thermocouple wire that set it apart from other thermocouples like type s thermocouple wire. For example, it provides extremely stable readings. This allows it to deliver accurate temperature readings. It also does not rust, which makes it a good material for wet or corrosive locations.

Once you select the right type of Type T thermocouple wire, ensure it is installed correctly to allow for an accurate temperature reading.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.