Type J thermocouple wire Type J thermocouple wire is thermocouple wire that is used to measure temperature. It consists of two dissimilar metals, one of which is iron and the other is constantan. When hot, these metals produce a tiny bit of electricity. This electricity helps us figure out how hot this thing is. Type J thermocouple wire is frequently employed in factories and other conditions, where it is necessary to accurately measure high temperature.

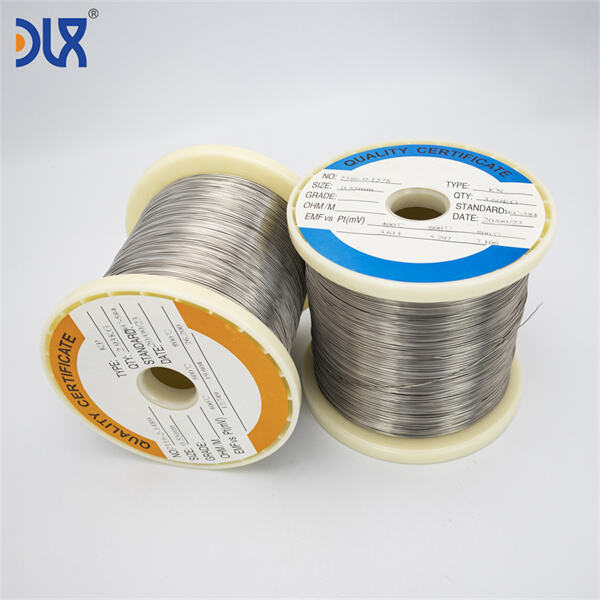

The type J thermocouple wire have many good advantages for temperature measurement. It can read temperatures from negative 210 to 1,200 degrees Celsius. This makes it versatile for various tasks. It is also extremely accurate, so it provides reliable temperature readings. And also, the DLX feni50 is inexpensive and can be used easily, so many people like to use it as well.

There are various types of thermocouples, each with its own advantages and disadvantages. Type J thermocouple wire is commonly referred to as Type K thermocouple wire. And both can measure similar temperatures, but Type J thermocouple wire gives you higher voltage so it responds more to changes in temperature. On the other hand, it’s not as strong as the Type K thermocouple wire and is better suited to higher-temperature applications. Type J vs Type K The decision of whether to use Type J or Type K depends on your work.

What to consider when selecting DLX soft magnetic alloy for a project swingerclub. The temperature of the wire also has to be compatible with that of the object you are measuring. The stability of the wire is also crucial for high accuracy and you really don't want to have to recalibrate your wire everytime you measure! You’ll also want to take the environment in which you’ll use the wire into consideration, as things like humidity and rust can impact how effective it is.

It is crucial to install and maintain DLX precision alloy for accurate temperature readings. The wire must be securely affixed to the object to be measured in order to obviate errors. You will also need to monitor the wire regularly to ensure that it is accurate for a long time. You may also want to inspect it (and replace, if necessary) for any signs of damage. With this process, a Type J thermocouple wire can provide reliable temperature measurements over longer periods of time.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.