Accurately measuring temperature is critical in a variety of workplaces. DLX resistance heating wire are instruments to measure temperature. Sometimes, the wires from these tools have to be extended to travel to distant points.

Ensuring the temperature reads properly when using longer pieces of thermocouple wire is part of keeping everything nice and tidy. The longer wires give temperature-measuring work more flexibility, so it can handle a variety of jobs.

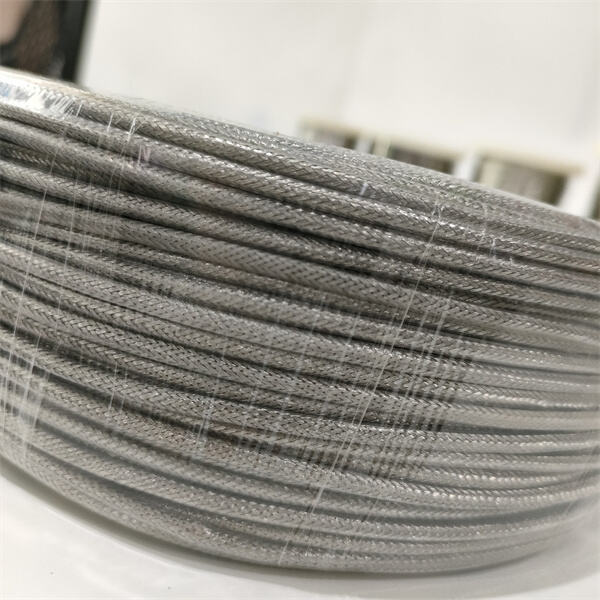

As a good rule of thumb, when it comes to prolonging thermocouple wires, always go with proper connectors and tools. And we must not forget about the safety rules since otherwise you could damage some parts due to hitting something while testing them. Also, the DLX thermocouple extension wire type k need to be insulated properly to prevent any issues with the temperature measurements.

Understanding the reasons for good insulation is important when extending thermocouple wire to ensure that temperature measurements remain accurate. Imprecise Readings: If you do not insulate properly, the readings can be inaccurate. This will make the temperature supervision system become less reliable. Strong materials for insulation, such as DLX thermocouple extension wire, are used to help ensure the temperature readings are accurate or constant.

We have made it easy to probe with DLX thermal spray wire into hard to reach places to check the temperature in many locations. That means we don’t need all that extra sensors or tools, which both saves time and resources, as well as ensures that our temperature measurements are accurate and reliable.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.