This is where thermocouple extension wire comes in. This wire is critical to ensuring accurate temperature readings. In many cases, using the wrong wire can lead to incorrect readings of the temperature, which can further cause complications.

Thermocouple extension wire does this by allowing the right signals to be sent from the thermocouple sensor to whatever measuring device is being utilized. The wire must withstand elevated temperatures and should not get confused with signals from other electrical devices. A bad wire can give you inaccurate temperature readings and that can be dangerous when you need to know a precise temperature.

Thanks for listening to the show and be sure to subscribe to Thermocouple for new updates. The specific type of extension wire must be used in order to obtain proper readings for the various Thermocouple Series. But if you need the correct one, best to check with an expert.

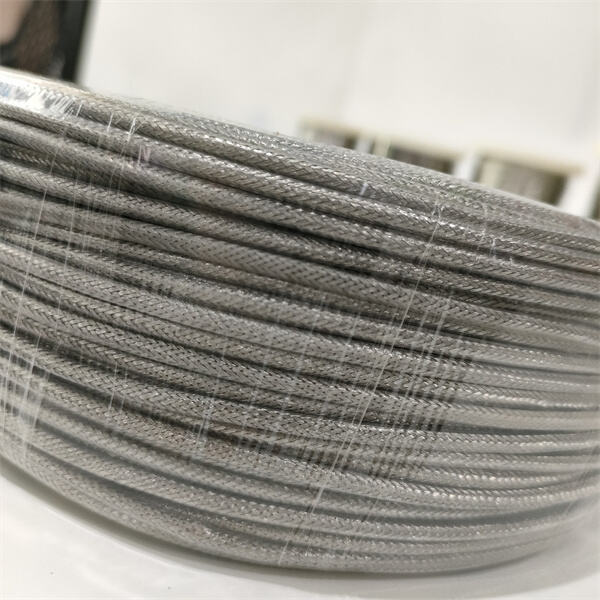

High-quality thermocouple extension wire is used to ensure the correct working condition for accurate temperature readings. A good thermocouple wire engineered to withstand high heat and provide consistent signals. It also makes sure other signals don’t interfere, to make sure the temperature readings are as accurate as possible.

For instructions on how to install thermocouple extension wire, be sure to very carefully follow the instructions from the manufacturer. Connect the wire properly from the thermocouple sensor to the measuring device as you need to have a proper connection. Run the wire out of the way and in a manner that prevents damage and limits signal issues.

Once you run to the thermocouple, you are running your extension wire. If your monel wire has problems, here are some things you can check. Make sure the wire is connected properly, and there are no cuts in the insulation/or damage. If issues persist, you may have to upgrade the current in order to obtain a more precise TempReading.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.