Thermocouples are special wires, capable of measuring temperature. One specific thermocouple wire is called Type S. A thermocouple: Two different metals produce an electric signal when they get hot. This signal tells us the temperature of something. Thermocouple Series wire made from Type S material is highly accurate and stable at high temperatures.

A type S thermocouple wire is widely used in industries due to its ability to withstand very high temperatures, generally to the extent of 1482 degrees Celsius. This is why it makes a good choice for furnaces, ovens, and other hot areas. It is also quite stable and provides consistent temperature readings over time. This type k thermocouple cable allows businesses to stay on track while continuing to monitor quality.

Type S thermocouple wire functions by measuring how small an electrical signal is created when the two metals heat and cool. A special tool called a thermometer converts this signal into a temperature reading. Both the thermocouple wire quality and the thermometer being used influence the accuracy of the temperature reading. Thermocouple resistance wire of type S is normal in terms of reliability and accuracy.

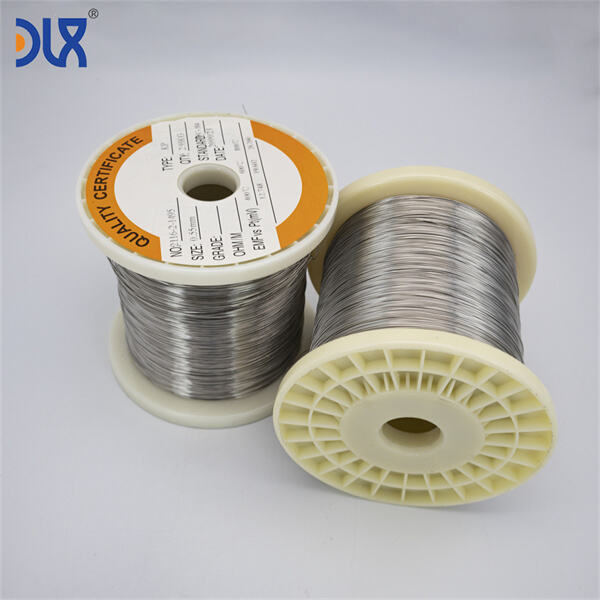

Different Types Of Temperature Pyrometry You Can Get In The Market: Some are thin and supple, others are thicker and stronger. Others are easy to install and some have protective coatings that help them withstand harsh conditions. Having the right Type S thermocouple wire type will allow businesses to obtain accurate temperature measurement types.

The Type S thermocouple wire has the following wiring applications When selecting Type S thermocouple wire for a particular application, considerations such as temperature range, durability, and requirements for precision should be taken into account. Types of Type S thermocouple wire that DLX provides in accordance with distinct industrial requirements. Companies can also work with our experts to determine which type of Type S thermocouple wire will be best for use in their own applications.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.