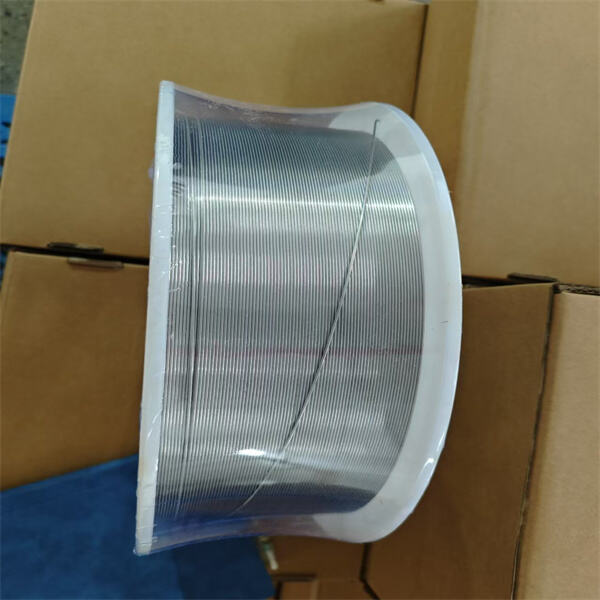

Choosing the right materials is crucial when you weld. One of those welding wires many people will make use of is pure nickel welding Wire. TIGerman Wire. This wire is a strong and long-lasting option for welding. DLX pure nickel welding wire is quite durable and has a long service life. This means, that when you use this wire for welding, you can be sure of strong and safe welds. The welds have to be solid for your projects to be safe and dependable. Using quality materials such as DLX pure nickel welding wire aids in achieving this.

You can use DLX pure nickel welding wire, which helps you to weld with a high degree of precision. This is because it is very clean and good quality. With this wire, you know your welds are clean and true. Whether welding small or larger pieces, DLX pure nickel strip for 18650 battery welding makes getting the right welds easy.

For any project requiring rust and corrosion resistance, DLX pure nickel welding wire is also a good insulated welding wire. Nickel does not rust so is ideal for outdoor or other more demanding projects. With DLX pure nickel wire, you know you're getting protection and durability for your welds.

Another reason why DLX pure nickel welding wire works so well is that it is extremely pure. That means that no ugly stuff is inside the wire, which leads to clean and accurate welds. DLX pure nickel wire will ensure your welds are solid and tidy.

In summary, DLX pure nickel welding wire is a professional welding tool that can ensure high-quality welding stably, and this welding wire is equipped with standard torch automatic feeding, which can process common pure nickel materials at a normal temperature. Large or small, depending on the size of your project you can achieve your hardware goals by using DLX pure nickel welding rod. DLX pure nickel welding wire is a superb solution for your welding projects with its strength, durability, and resistance to corrosion.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.