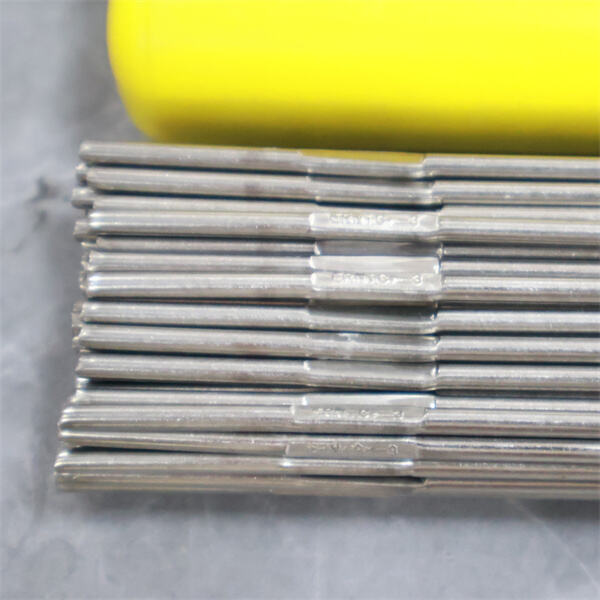

The nickel welding rod are cut into small pieces and can be include into a group of metal pieces using an electromagnet or other method. They are used to create cars, bicycles, and large structures. The joints are very durable and these rods are built from nickel which is a strong metal.

Using nickel welding rods ensures the most robust and long-lasting joints we can get. This means that whatever we produce won't just disintegrate or break apart. This nickel gives the epoxies, which make up the rods, strength and toughness to withstand loads and produce low viscosity joints. That seems important because we want what we make to last.

Rust is when metal becomes weak because of water and air. Nickel welding rods can help prevent this. The pure nickel welding rod is great at resisting rust which means the joints we form will not breakdown easily over time. This is super crucial for items you might use outside, or in places that may get wet.

Nickel welding rods may sound difficult at first but, with practice, and the right techniques, we can get better at welding nickel rods. It can be very helpful to ensure that the metal parts are clean before welding for beginners. This serves to create a strong bond between the pieces. Another approach is to employ enough heat and pressure during welding to ensure that joints are tight and strong.

Nickel welding rods can be used when we know what we are doing. To begin with, all the nickel strip, welding machine, and safety gear like gloves and a helmet should be collected. Finally, we do some practice on older pieces Scrap metal after all before welding on our actual project to get an idea of the welding works. And now we are ready to start welding our pieces to each other the proper way to make strong bonds.

I think the secret to success with nickel weld rods is just practice and patience. Welding might take some practice to get comfortable with but note that we are capable of creating robust and durable joints with effort and methods. By learning the rules and paying attention to the details we can be experts using pure nickel strip and build awesome things.

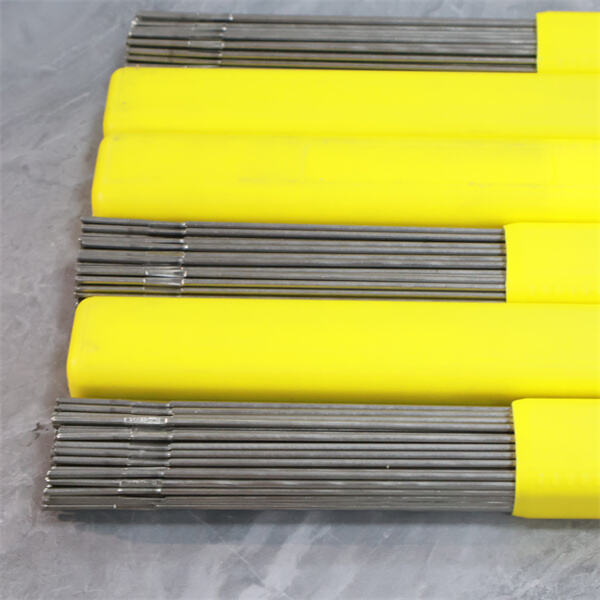

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.