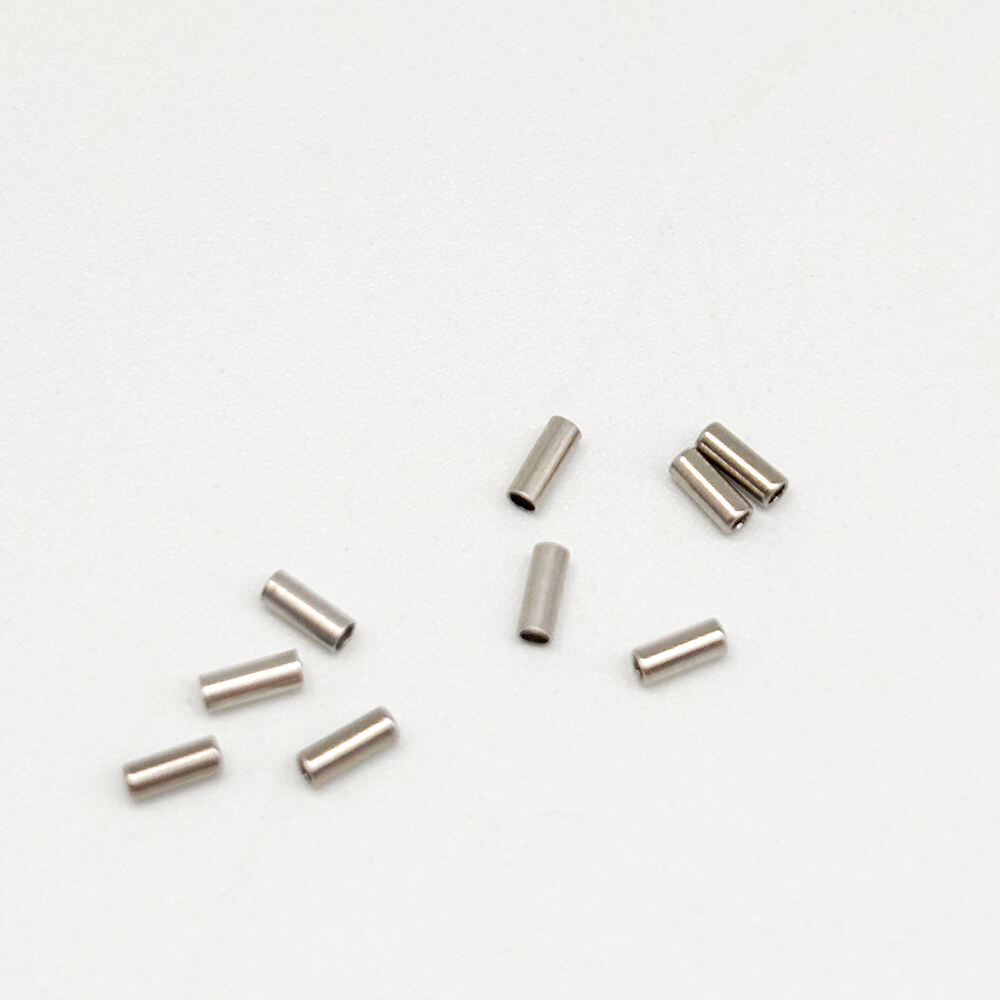

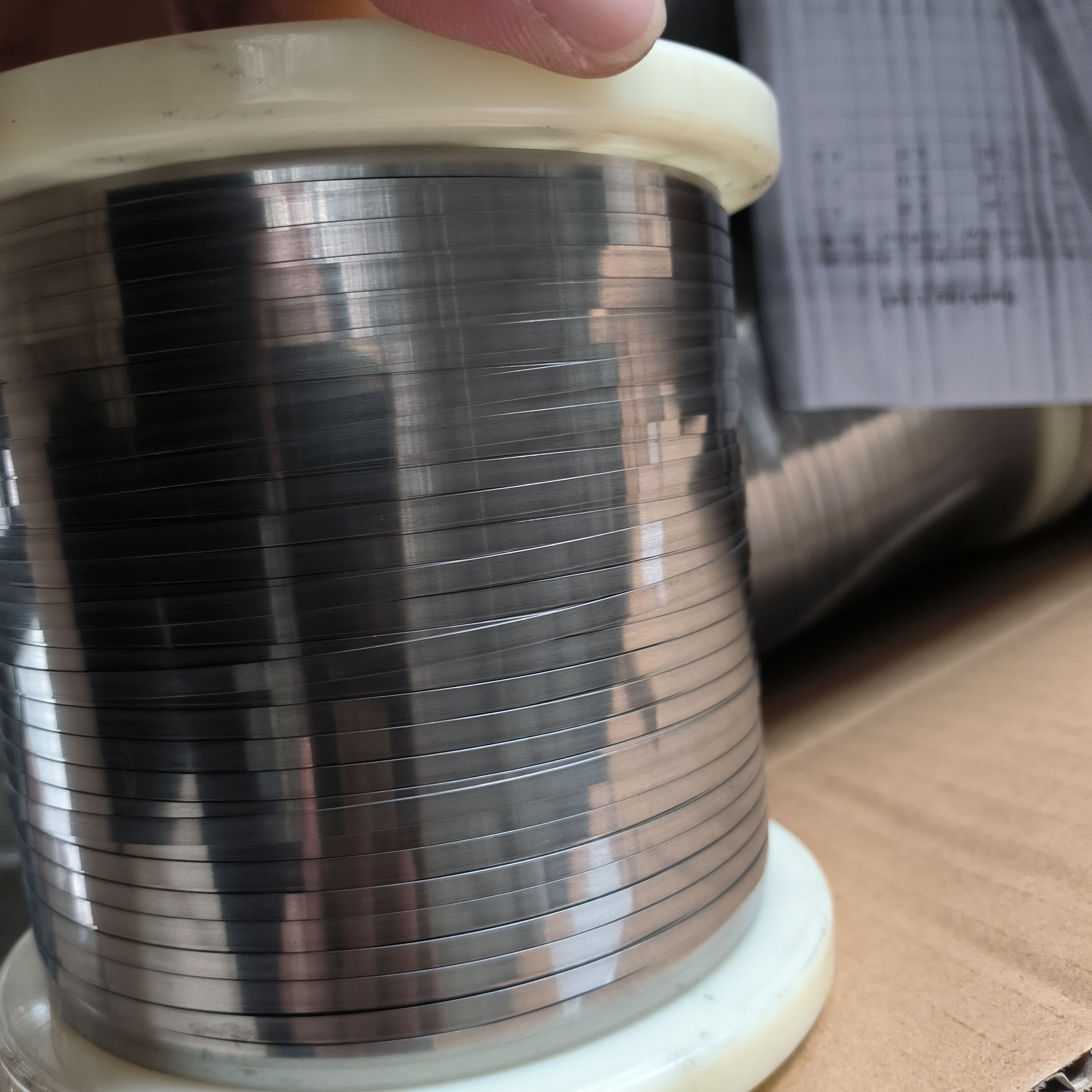

Welded Nickel Capillaries – Cost-Effective Solution for HVAC & Refrigeration

High purity ensures accurate analytical results

Excellent corrosion resistance for handling aggressive solvents

Superior mechanical strength for high-pressure systems

Seamless design minimizes contamination risks

Reliable performance in precision laboratory applications

Place of Origin: China Jiangsu

Certification: CE,ROHS

Nickel 200 (UNS N02200) Nickel 201 (UNS N02201)

Why Choose Us?

22+ years in battery materials manufacturing.

Global shipping with DDP options.

- Overview

- Recommended Products

Our Welded Nickel Capillaries are the perfect pick for HVAC and refrigeration systems when you want performance without breaking the bank. Made from nickel or nickel alloys, these capillaries deliver the durability and efficiency you need, and we’re thrilled to have them in our lineup.

Grade |

Ni+Co |

Cu |

Si |

Mn |

C |

Mg |

S |

P |

Fe |

N4 |

99.9 |

≤0.015 |

≤0.03 |

≤0.002 |

≤0.01 |

≤0.01 |

≤0.001 |

≤0.001 |

≤0.04 |

N6 |

99.5 |

0.10 |

0.10 |

0.05 |

0.10 |

0.10 |

0.005 |

0.002 |

0.10 |

Ni201 |

≥99.9 |

≤0.25 |

≤0.35 |

≤0.35 |

≤0.02 |

/ |

≤0.01 |

/ |

≤0.40 |

Ni200 |

≥99.6 |

≤0.25 |

≤0.35 |

≤0.35 |

≤0.15 |

/ |

≤0.01 |

/ |

≤0.40 |

CHEMICAL COMPOSITION | |||||||

Alloy |

Ni+Co % |

Mn % |

Fe % |

Si % |

Cu % |

C % |

S % |

Nickel 201 |

Min 99.2 |

Max 0.35 |

Max 0.4 |

Max 0.35 |

Max 0.25 |

Max 0.02 |

Max 0.01 |

Nickel 200 |

Min 99 |

Max 0.35 |

Max 0.4 |

Max 0.35 |

Max 0.25 |

Max 0.15 |

Max 0.01 |

Physical Data | |||||

Density |

Specific Heat |

Electrical Resistivity |

Melting Point |

Thermal Conductivity |

Mean Coeff Thermal Expansion |

8.89g/cm3 |

0.109(456 J/kg.℃) |

0.096×10-6ohm.m |

1435-1446℃ |

70.2 W/m-K |

13.3×10-6m/m.℃ |

What makes these capillaries awesome? They’re a budget-friendly option that doesn’t skimp on quality. They’ve got great thermal conductivity, so they handle heat transfer like a pro, keeping your refrigeration system running smoothly. Plus, they’re tough enough to deal with high-pressure refrigerants like Freon or ammonia without batting an eye. And don’t worry about corrosion—they’re built to resist it, even in harsh, humid conditions.

We love how adaptable they are. Need a specific size or shape for your HVAC setup? We can customize these capillaries to fit your system perfectly. They’re also super reliable, giving you consistent performance over the long haul, which means less maintenance and more uptime for your equipment.

The HVAC and refrigeration industry is all about efficiency and sustainability right now, with trends pushing for greener cooling solutions and energy savings. Our Welded Nickel Capillaries are right on board with that, offering a cost-effective way to keep systems running efficiently while cutting down on waste. As demand for better cooling tech grows—especially in hot regions like Asia-Pacific—we’re ready to step up.

With our Welded Nickel Capillaries, you’re getting a solution that’s affordable, durable, and perfect for HVAC and refrigeration needs. It’s the smart choice for keeping your systems cool and your costs down.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

1、What are Welded Nickel Capillaries made of?

They’re made from nickel or nickel alloys, known for their durability and corrosion resistance.

2、Why are they used in HVAC and refrigeration?

Their thermal conductivity and pressure resistance make them ideal for efficient refrigerant flow.

3、How do welded capillaries compare to seamless ones?

Welded capillaries are more cost-effective while still offering reliable performance for many applications.

4、Can they handle refrigerants like Freon or ammonia?

Yes, they resist corrosion from common refrigerants, ensuring long-lasting performance.

5、Are these capillaries suitable for high-pressure systems?

Absolutely, they’re designed to handle the pressures found in HVAC and refrigeration setups.

6、Can the dimensions be customized?

Yes, we can tailor the size and shape to fit your specific system needs.

7、What industries benefit from these capillaries?

Besides HVAC and refrigeration, they’re used in automotive cooling, aerospace, and industrial cooling systems.

8、How long do welded nickel capillaries last in refrigeration systems?

With their corrosion resistance and durability, they’re built to last for years in tough conditions.