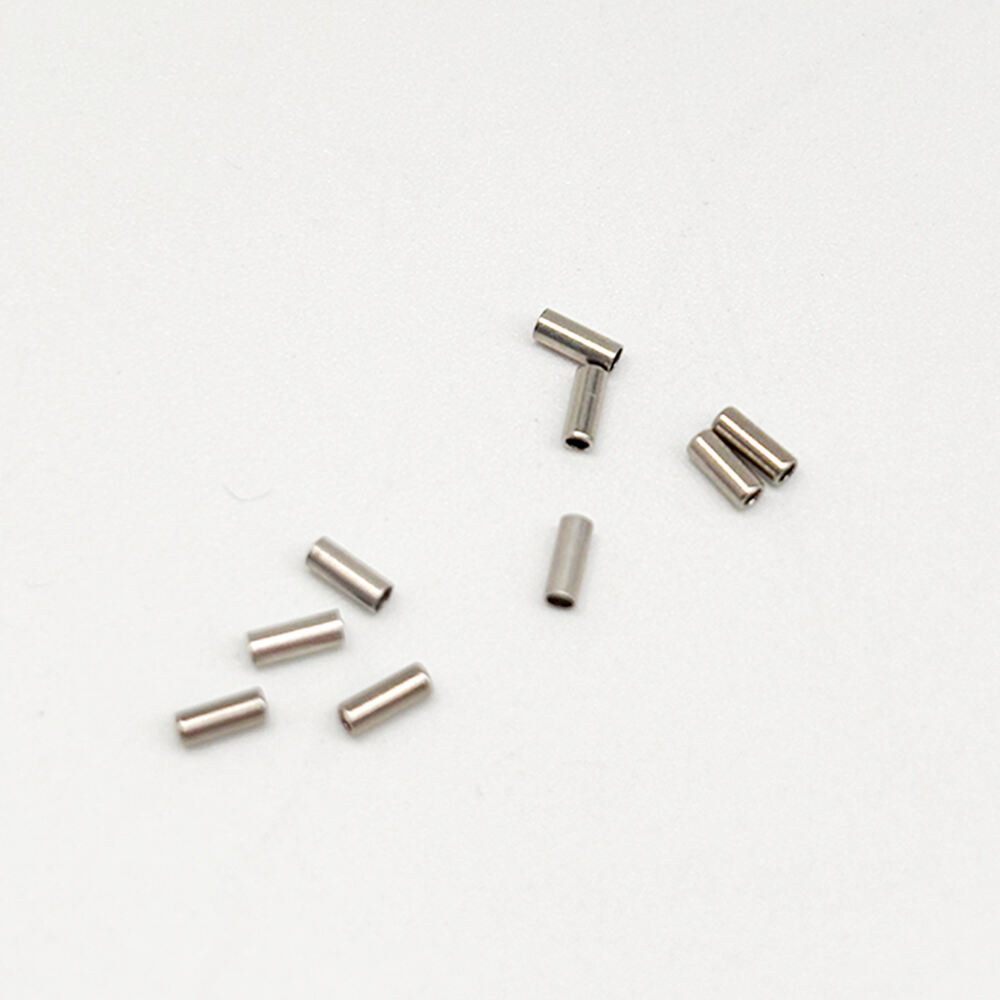

High-Quality Pure Nickel Capillaries – Precision Tubes for Electronics & Sensors

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

High-Quality Pure Nickel Capillaries – Precision Tubes for Electronics & Sensors

When precision, purity, and reliability matter most, pure nickel capillary tubes are hard to beat. At our company, we’ve been supplying these tiny yet powerful components to clients in electronics, sensor manufacturing, and scientific instrumentation for years — and we’ve seen their performance hold up in some of the most demanding environments.

So, what makes high-quality pure nickel capillaries such a go-to solution? Let’s break it down.

What Are Pure Nickel Capillaries?

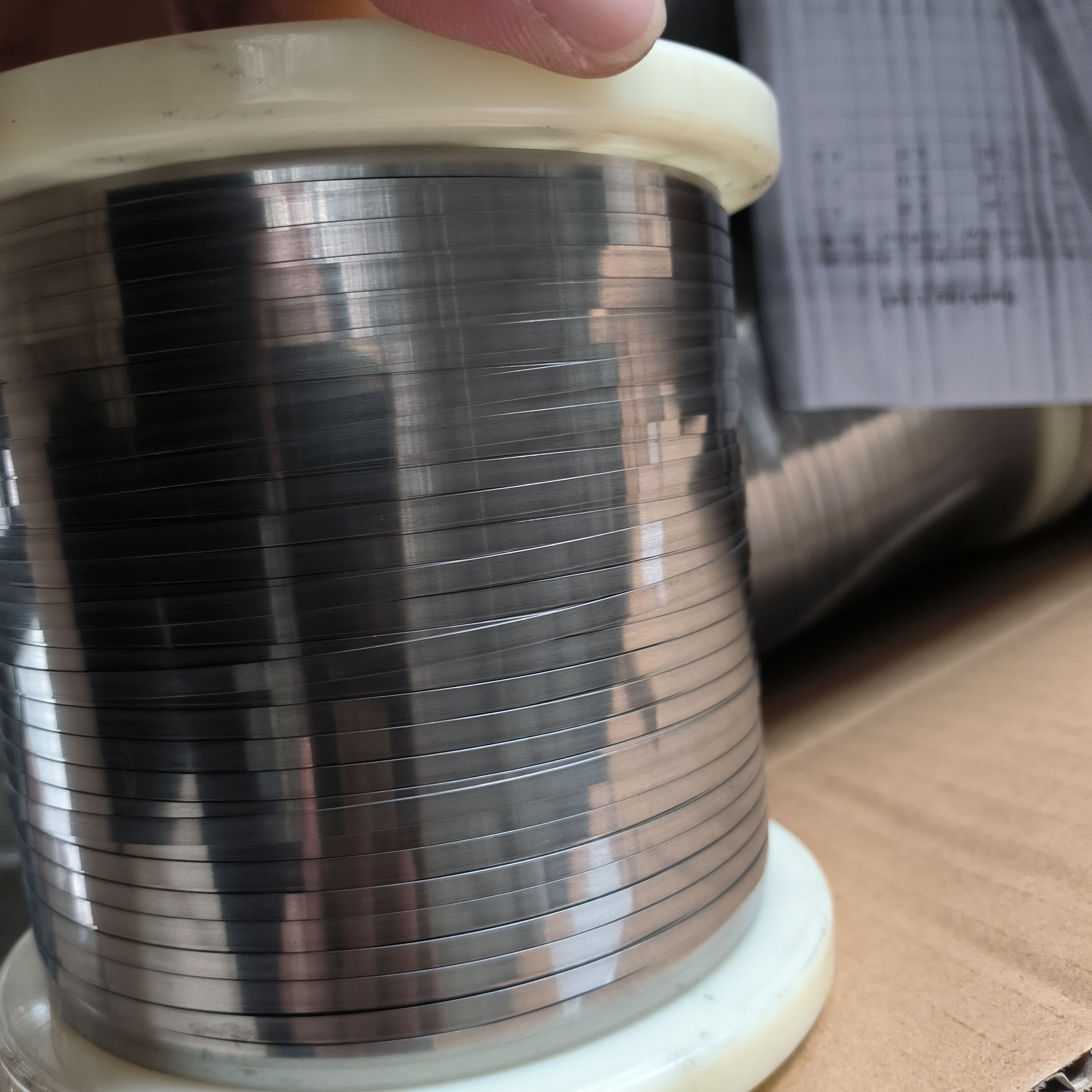

These are ultra-thin, small-diameter tubes made from high-purity nickel — typically Nickel 200 or 201. With excellent corrosion resistance, thermal conductivity, and electrical properties, they’re perfect for precision applications that require clean, stable performance.

Thanks to their tight dimensional tolerances and smooth internal surfaces, these capillaries ensure consistent flow of gases or fluids, making them ideal for highly sensitive and compact systems.

Why Are They So Popular in Electronics & Sensors?

In electronics and sensor applications, small size and precision are key — but so is material stability. That’s where pure nickel stands out. It offers:

Excellent electrical conductivity

Superior corrosion resistance, even in harsh environments

Non-reactive surfaces — ideal for clean signal transmission

Thermal stability, especially in fluctuating temperatures

We’ve seen customers use our nickel capillaries in everything from temperature sensors and gas analyzers to MEMS devices and battery management systems. Wherever clean signals or precise control of microfluidics are needed, these tubes deliver.

Common Applications

Here’s where high-quality nickel capillaries shine:

Sensor housings and leads

Signal line protection in harsh or high-temp environments

Laboratory instrumentation

Fuel cell components

Thermocouple sleeves

Vacuum or gas transfer systems

We also supply custom capillaries for research labs and R&D projects, where experimental setups require ultra-clean, non-contaminating tubing.

Industry Trends: Why Demand is Rising

In the past few years, we’ve seen demand for these tubes grow — and it’s no surprise why:

Miniaturization is everywhere — especially in electronics and IoT sensor devices.

Reliability is now a top priority in industries like aerospace, defense, and medical tech.

Clean energy and EV sectors are pushing for higher-quality sensor and battery components.

As systems get smaller and more advanced, materials like pure nickel become more important — offering both performance and peace of mind.

Our Promise

We don’t just supply tubing — we supply solutions. Whether you're designing a high-end sensor or building out a precision instrumentation line, our pure nickel capillary tubes are manufactured to exacting standards, with tight tolerances, clean inner surfaces, and full material traceability.

Need something custom? No problem — we offer:

Custom OD/ID sizes

Coils or straight lengths

Polishing, cleaning, and annealing services

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

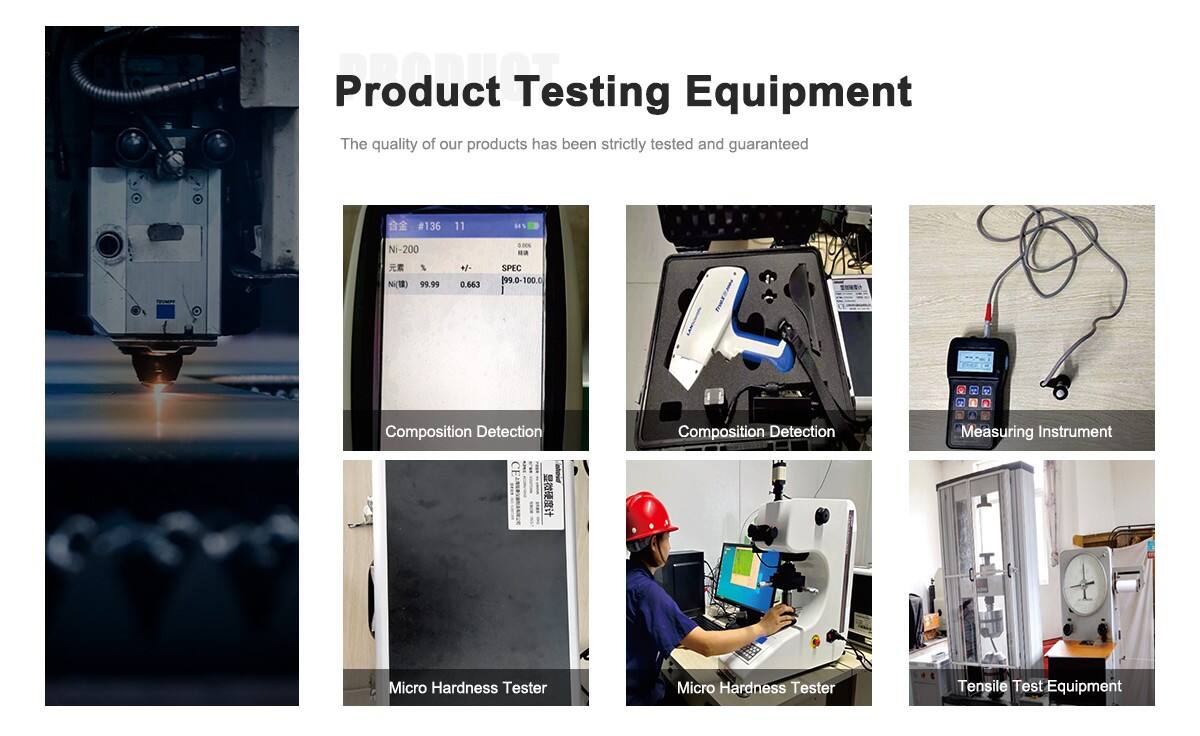

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.