Seamless Nickel Capillary Tubes – Ideal for Semiconductor & Vacuum Systems

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

These tubes are crafted from high-purity nickel (typically Nickel 200 or 201) and drawn down to incredibly small diameters with tight tolerances. The seamless structure means there are no weak points or welds, which is critical in environments that demand leak-free performance and absolute consistency.

Here’s what makes them stand out:

Excellent corrosion resistance, especially in vacuum and reactive gas environments

High thermal and electrical conductivity

Non-magnetic and low outgassing, ideal for ultra-high vacuum (UHV) systems

Outstanding purity, which prevents contamination of sensitive processes

Perfect for Semiconductor & Vacuum Systems

Semiconductor fabrication is all about precision at the microscopic level. Contaminants, leaks, or thermal instability can cause massive defects in a production line. That’s why our customers in chip manufacturing and cleanroom environments rely on seamless nickel capillaries for:

Gas delivery lines

Chemical vapor deposition (CVD) equipment

Plasma etching systems

Sensor and thermocouple protection

Leak-proof vacuum feedthroughs

In vacuum technology, especially UHV and cryogenic applications, the benefits are just as clear. These tubes perform reliably under:

Extreme negative pressures

High thermal cycling

Exposure to reactive or corrosive gases

What’s Driving Market Demand?

We're seeing a sharp rise in demand, and here’s why:

Semiconductor industry growth: With AI, 5G, and electric vehicles booming, chip production is expanding rapidly—and so is the need for contamination-free systems.

Miniaturization: As devices shrink, tolerances tighten. Capillary tubes are now used in microfluidic and nano-scale delivery systems.

Vacuum tech innovation: From space science to advanced optics, vacuum systems are going deeper, cleaner, and more complex. That requires better materials.

Global clean energy shift: Nickel’s chemical resistance makes it a top choice in hydrogen energy and fuel cell research too.

Our Advantage

We supply custom-length, high-purity seamless nickel capillary tubes with:

OD ranges as small as 0.3 mm

Wall thicknesses down to 0.05 mm

Bright annealed or cold-drawn finish

Cleanroom packaging available

Strict ASTM B161 and B622 standards compliance

We know these tubes aren’t just components—they’re critical to system performance. That’s why quality control, fast turnaround, and expert guidance come standard with every order.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

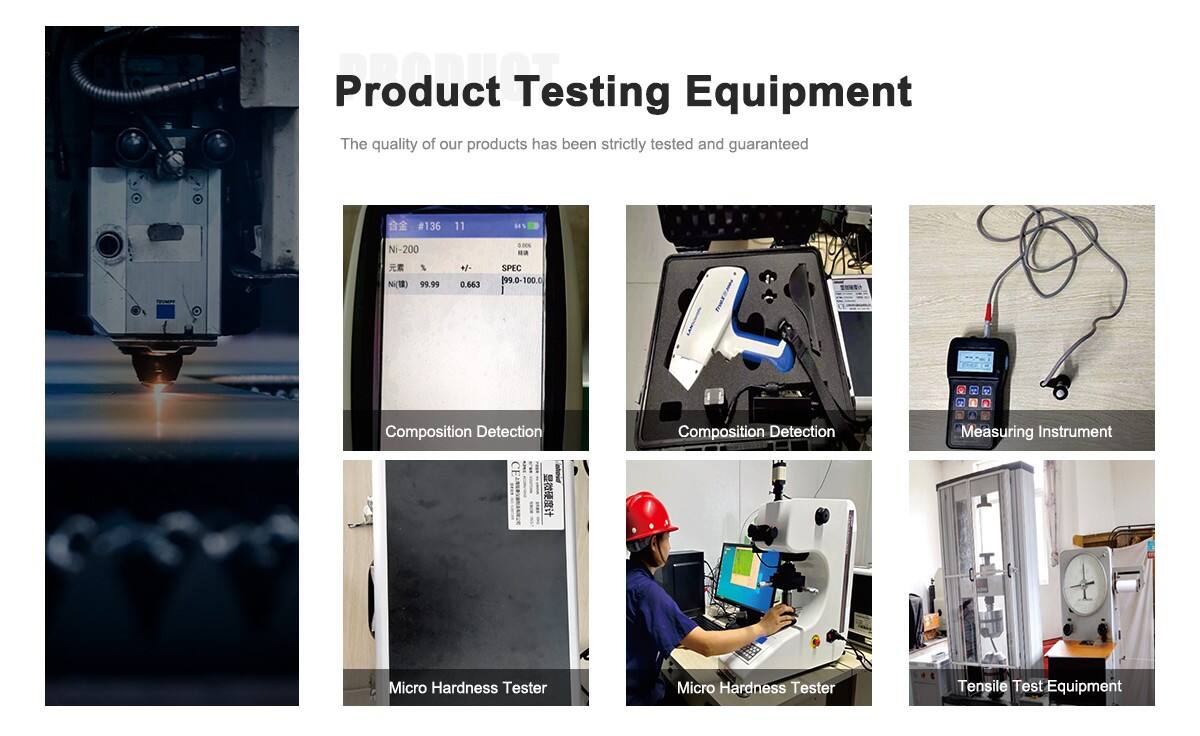

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.