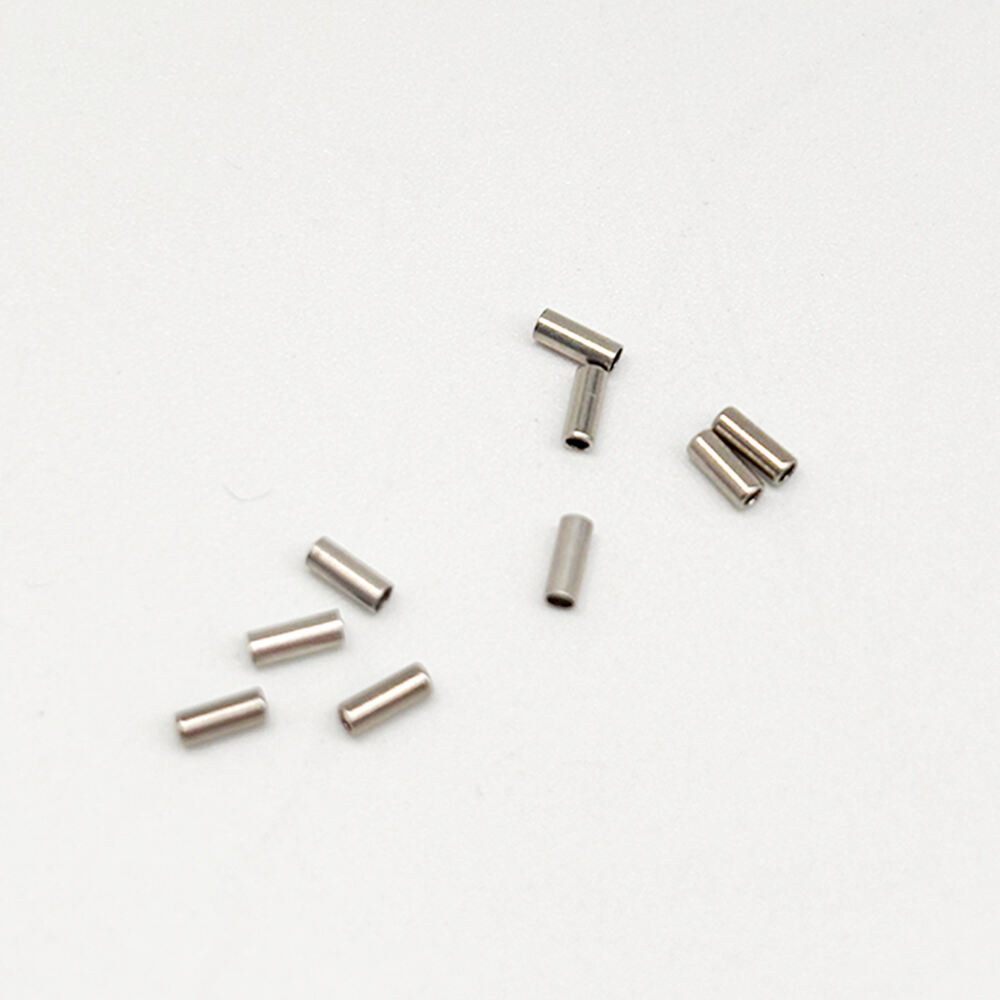

1.2*0.2 Pure Nickel Capillary Tubing – Superior Conductivity for Electrical Components

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

Pure Nickel Capillary Tubing – Superior Conductivity for Electrical Components

When it comes to electrical components, performance is all about precision and reliability — and that starts with the materials. At our company, we’ve worked with customers in electronics, energy, and instrumentation, and one thing is clear: pure nickel capillary tubing is becoming a go-to choice for engineers who need top-tier conductivity and durability in compact systems.

Why Pure Nickel?

We typically use Nickel 200 or Nickel 201, known for their high nickel content (99.6%+), excellent electrical and thermal conductivity, and strong resistance to corrosion. Unlike other materials, pure nickel maintains its integrity even in harsh or high-heat environments, which is critical for today’s advanced electronics.

Some key advantages:

High electrical conductivity

Corrosion resistance — ideal for humid or chemically active environments

Non-magnetic and stable in a wide temperature range

Great formability and weldability, perfect for precision assemblies

Where Are These Tubes Used?

We see pure nickel capillary tubes used in a wide range of electrical and electronic systems, including:

Battery management systems (BMS) – for safe, low-resistance pathways

Connectors and terminals in harsh environments

High-reliability signal transmission in aerospace or military devices

Micro-electronic sensors and probe components

Electromagnetic shielding and grounding applications

These tubes are also used as lead tubes for thermocouples and current-carrying elements in ultra-compact systems.

What's Driving Demand?

Several market trends are pushing pure nickel tubing to the forefront:

Miniaturization of electronics – As devices get smaller, materials must handle the same power in tighter spaces.

Electrification of everything – From EVs to IoT, modern systems rely on stable, low-loss electrical pathways.

Demand for reliability – In aerospace, medical, or industrial electronics, failure is not an option. Nickel offers long-term stability.

Sustainability focus – Nickel is fully recyclable, and its long service life reduces waste in high-end systems.

In short, engineers and designers are looking for performance over price — and pure nickel delivers.

Our Offering

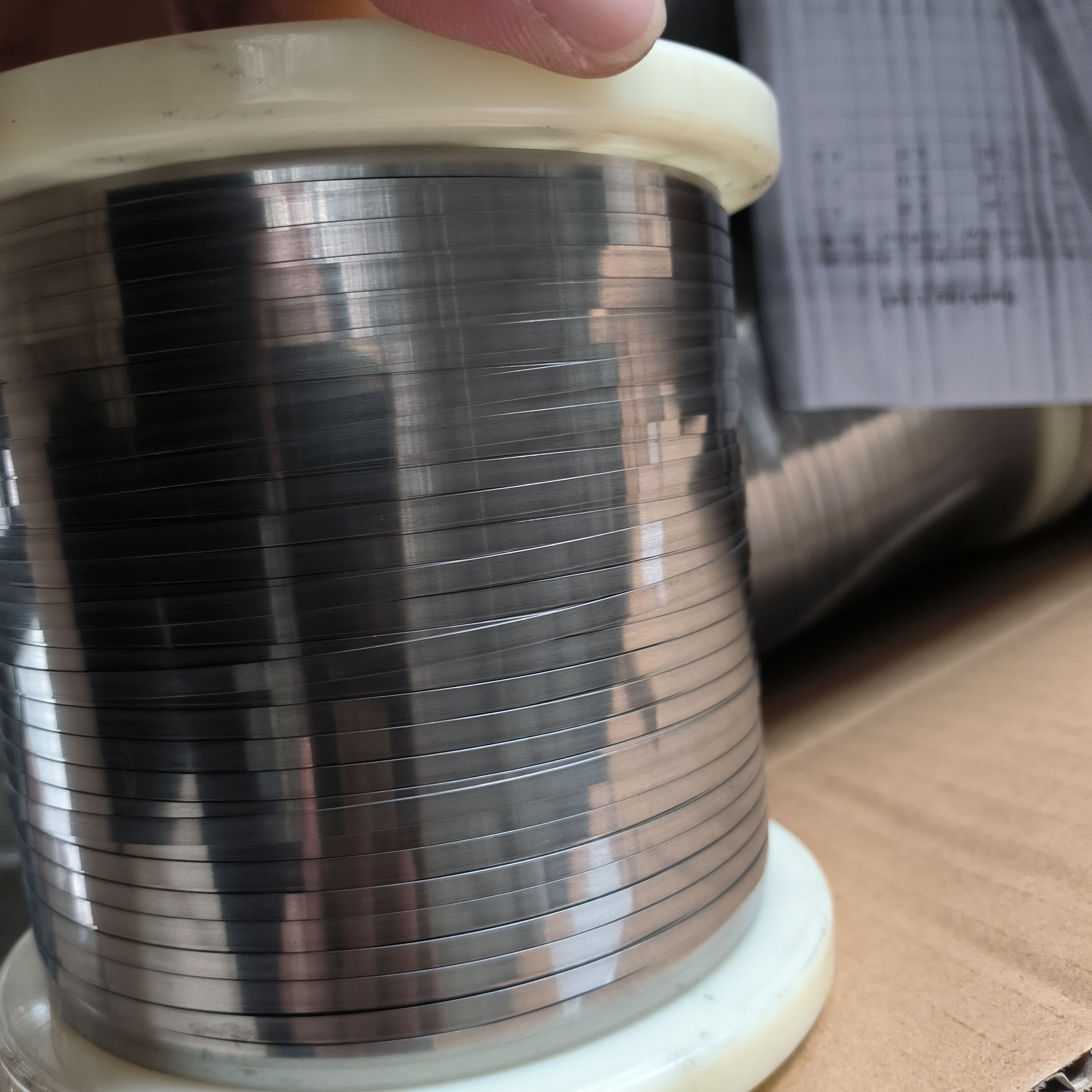

We manufacture and supply tight-tolerance pure nickel capillary tubes, with:

Outer diameters down to 0.3 mm

Wall thicknesses as low as 0.05 mm

Clean, burr-free inner surfaces for smooth current flow

ASTM B161/B622-compliant materials

Custom lengths and finishes (bright annealed, cold drawn, etc.)

Whether you're prototyping or in full production, we support your project with reliable materials, fast delivery, and technical expertise.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

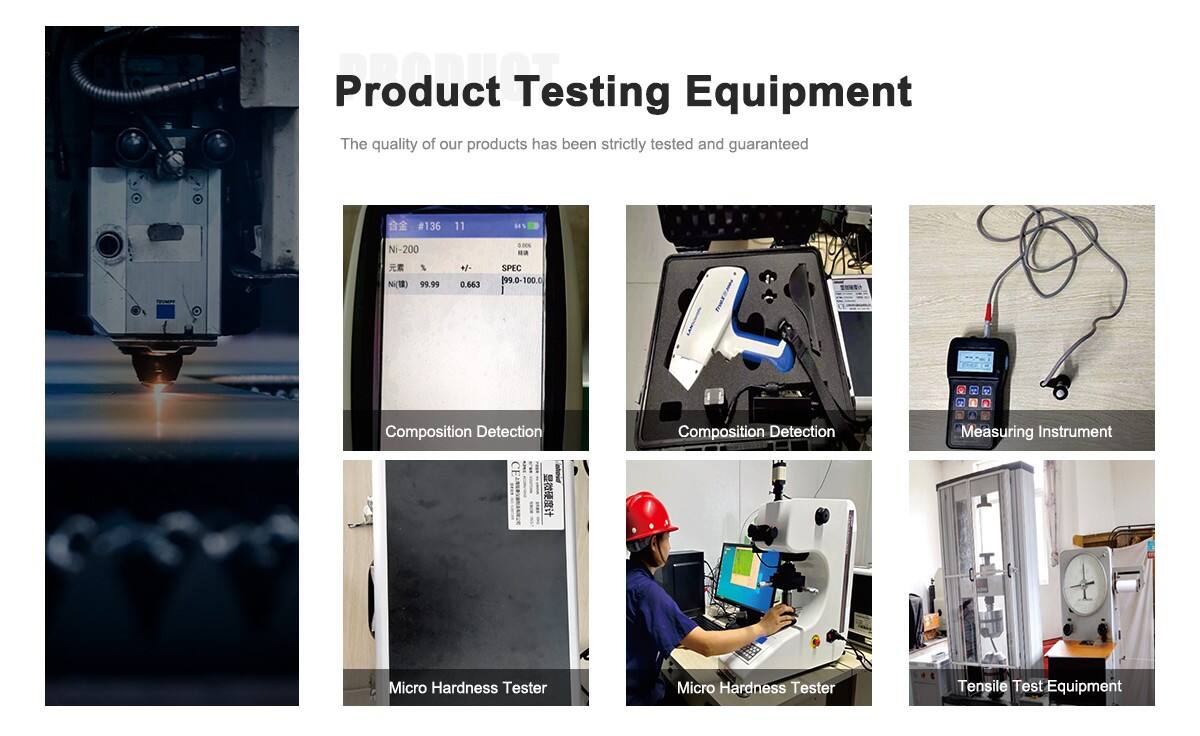

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.