Nickel 201 Capillary Tubes – Low-Carbon Pure Nickel for High-Temperature Applications

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

When you're dealing with high temperatures and corrosive environments, not just any material will do. At our company, we've seen firsthand how choosing the right metal makes a huge difference in the performance, longevity, and safety of critical systems. One material that's been standing out lately? Nickel 201 capillary tubes.

What Is Nickel 201, and Why Does It Matter?

Nickel 201 is a low-carbon version of Nickel 200, offering all the same purity and corrosion resistance — with better performance at elevated temperatures. With a maximum carbon content of 0.02%, Nickel 201 helps avoid embrittlement and intergranular attack that can occur in high-heat environments.

In short: Nickel 201 is what you choose when you need pure nickel that holds up under heat.

Why Capillary Tubes?

Capillary tubes are thin-walled, precision tubes used in:

Instrumentation and control systems

High-purity chemical sampling lines

Thermocouple protection tubes

Fluid and gas metering systems

Now, combine that tight precision with Nickel 201's temperature resistance and chemical stability, and you’ve got a solution that's ideal for high-temperature chemical processing, power plants, and lab-grade systems.

Where Are They Used?

We’ve supplied Nickel 201 capillary tubing to industries like:

Chemical processing – especially where caustics like sodium or potassium hydroxide are involved

Aerospace – for thermal control and fuel handling at high altitudes

Electronics – in manufacturing where purity and resistance to contamination matter

Nuclear and power generation – where heat and corrosion resistance are mission-critical

It’s also a smart choice in pharmaceutical and food processing equipment, thanks to its resistance to contamination and ease of cleaning.

Industry Trends: Why Demand Is Growing

We’re seeing rising interest in Nickel 201 capillary tubes, and here’s why:

Energy efficiency and high-temperature systems are becoming more common — especially in new-generation power plants and clean energy facilities

Instrumentation and automation are scaling fast, particularly in process industries

There’s a growing global push for durable, low-maintenance materials that reduce system downtime

More companies are shifting from traditional stainless steel to specialty alloys like Nickel 201 when failure isn’t an option.

Our Perspective

From our experience, Nickel 201 capillary tubes are an ideal long-term investment for precision systems operating under high stress. You get the strength and chemical resistance of nickel — without the drawbacks of carbon-related degradation.

We stock a wide range of sizes and offer custom fabrication for exact specs. Whether you need a few meters or a bulk order for industrial systems, we’re ready to support you with technical advice, fast shipping, and consistently high quality.

Need help choosing the right alloy or dimensions for your application?

Talk to our team — we’ll make sure you get the right tubing, with zero guesswork.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

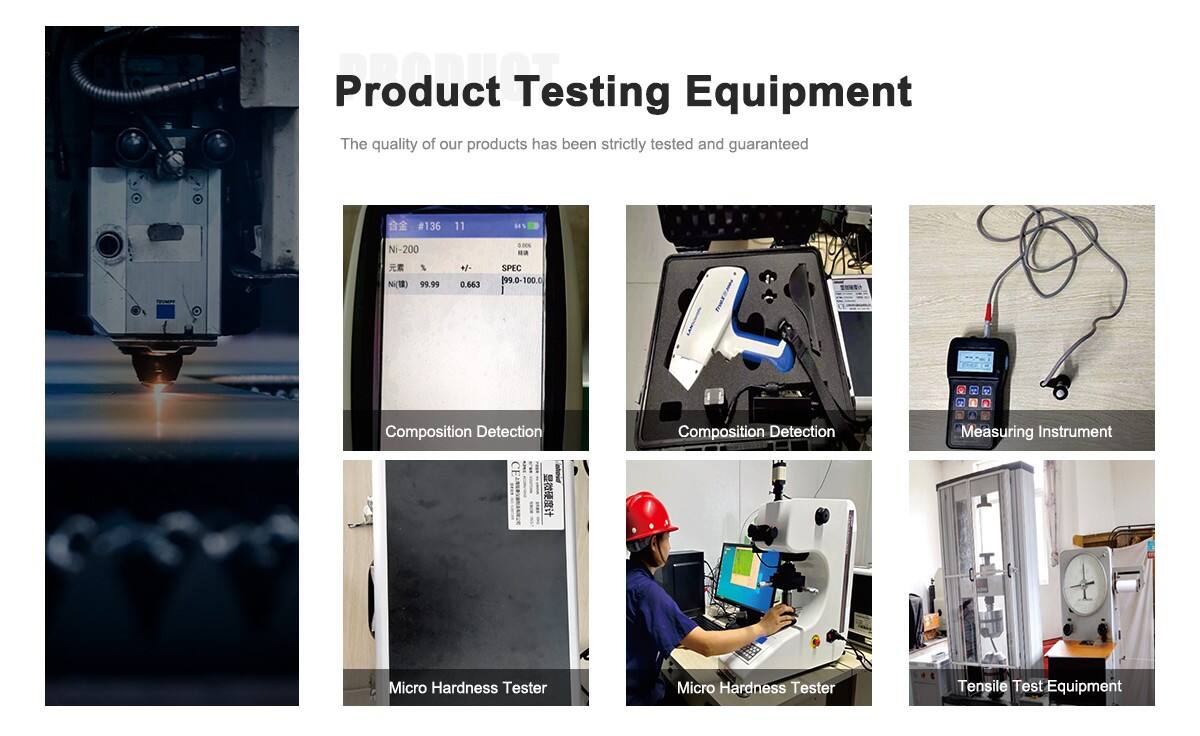

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.