ASTM B161 Nickel Capillary Tubes – Reliable Performance in Harsh Environments

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

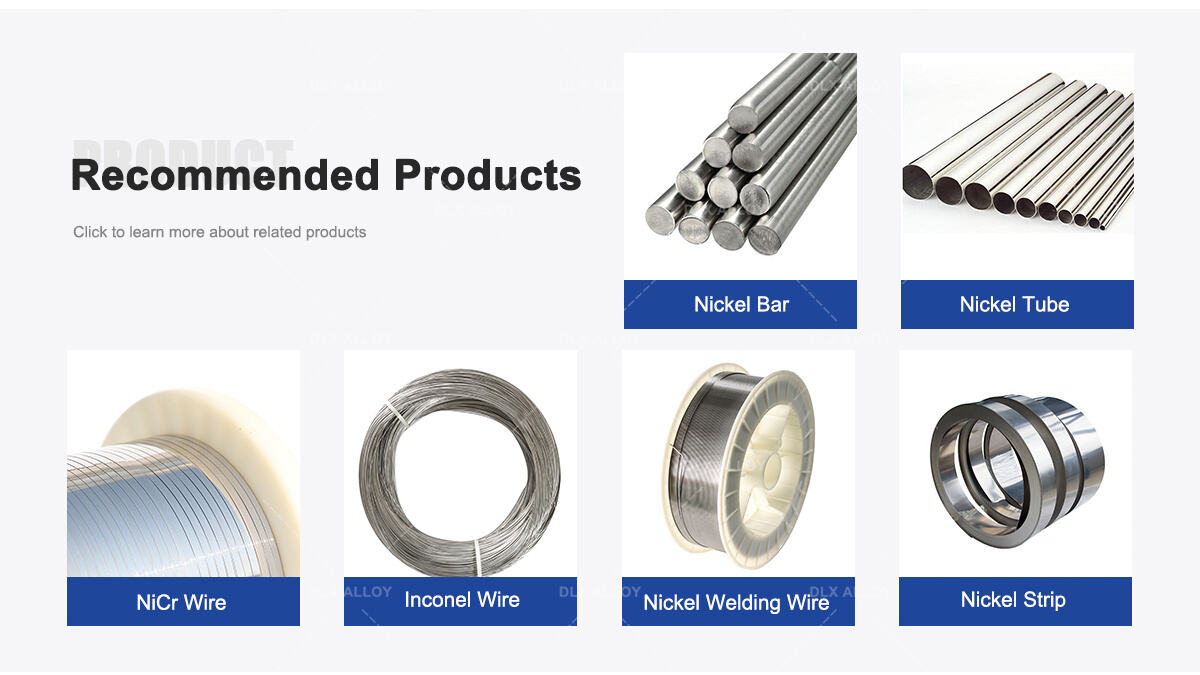

- Recommended Products

When your system is operating in harsh conditions—think corrosive chemicals, high temperatures, or extreme humidity—you need components that won’t back down. At our company, we’ve seen firsthand how ASTM B161 nickel capillary tubes deliver the kind of long-term, stable performance our customers can count on.

Whether you're in chemical processing, energy, or instrumentation, these tubes offer a combination of durability, purity, and precision that’s hard to beat.

What Exactly Is ASTM B161?

ASTM B161 is a standard specification for seamless nickel and nickel-alloy pipe and tube, specifically designed for applications where strength and corrosion resistance are non-negotiable.

Our capillary tubes made to ASTM B161 standards are typically produced using Nickel 200 or Nickel 201, offering:

High chemical purity (over 99.6% Ni)

Exceptional corrosion resistance in both neutral and alkaline environments

Excellent mechanical strength, even under stress

Great thermal and electrical conductivity

These properties make ASTM B161 nickel capillaries ideal for demanding industrial environments.

Why Use Capillary Tubes?

Capillary tubes are small-diameter, high-precision tubes often used in:

Instrumentation systems

Gas chromatography and chemical sampling

Microfluidic systems

Sensor protection and thermocouple sleeves

Flow control and metering equipment

When these systems are exposed to chemicals, heat, or pressure, the tubing material must not fail. That’s where ASTM B161 nickel capillaries come into play—reliable, consistent, and corrosion-resistant.

Key Industries & Applications

We supply ASTM B161 nickel capillary tubes to customers across multiple sectors:

Chemical and Petrochemical Processing

Ideal for handling caustic solutions like sodium or potassium hydroxide

Power Generation

Used in high-temperature steam systems and nuclear applications

Electronics & Instrumentation

Perfect for signal line protection, probes, and miniature sensors

Aerospace and Defense

Lightweight, corrosion-resistant tubing for mission-critical systems

Medical & Lab Equipment

Where precision flow and non-contamination are essential

Market Trends: Why Nickel Is Gaining Ground

We're seeing increased demand for ASTM-grade nickel tubes—and it's not just because of material specs. It's about solving real-world industrial challenges.

Environmental regulations are pushing industries to choose safer, longer-lasting materials

High-precision systems require capillaries with tighter tolerances and better performance under stress

The rise of clean energy and advanced manufacturing is fueling growth in high-purity, high-stability materials

Customers are no longer just looking for the cheapest solution—they want something that lasts, performs, and delivers value over time.

Why Choose Us?

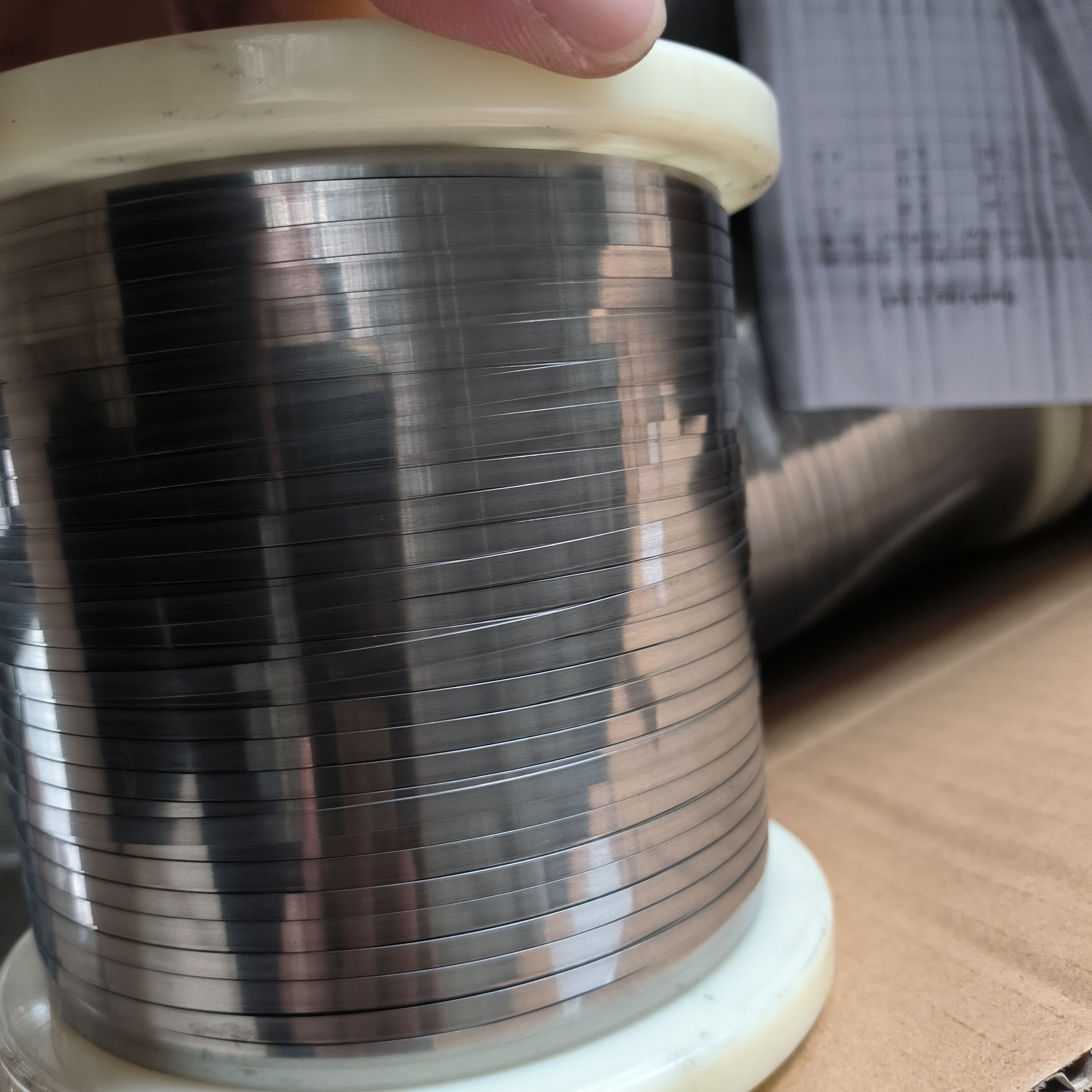

We offer ASTM B161-compliant capillary tubes in a wide range of outer diameters and wall thicknesses, with:

Tight dimensional tolerances

Clean internal surfaces

Options for bright annealing, polishing, and coil forms

Fast turnaround times and custom solutions

Every tube is inspected and tested to meet international standards — because we know your system can't afford surprises.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

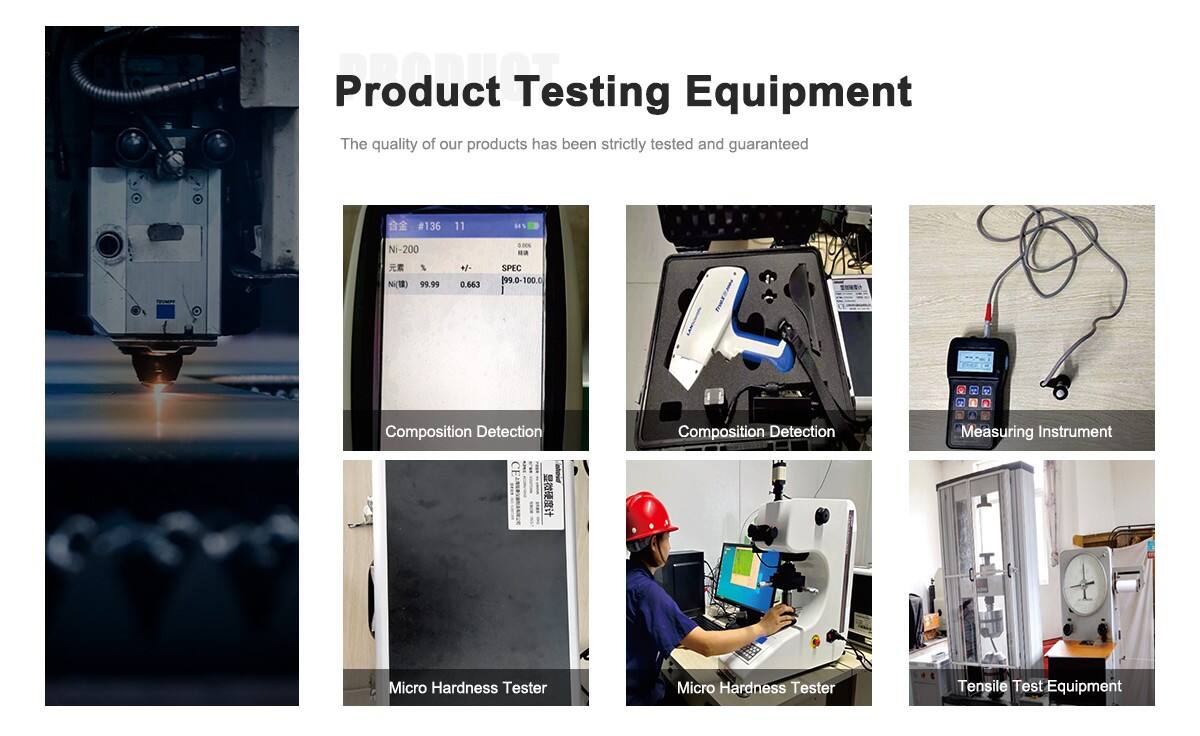

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.