Heating wire is a special kind of wire that makes heat when electric current flows through. This technology is altering our remedy our homes and business heat, making it more cost-effective. First, we will discuss heating wire and its significance in the optimization of heating systems globally.

Heating wire functions through metallurgical resistance in an electrical conductor to generate heat, also the DLX's product such as resistance wire. When electricity passes through this wire, small particles called electrons travel through it and rub against the wire, causing heat.

Heating wire is the better and more reliable way to heat space and is revolutionizing heating systems, just like the Incoloy material produced by DLX. It is more energy efficient than traditional gas or oil heaters, and can be regulated much better.

Type heating wire is used around factories for heating machines and equipment, also the DLX's product such as titanium bar. With heating wire, businesses can ensure that their machines operate at the appropriate temperature. This can stabilize their performance and prevent breakdowns.

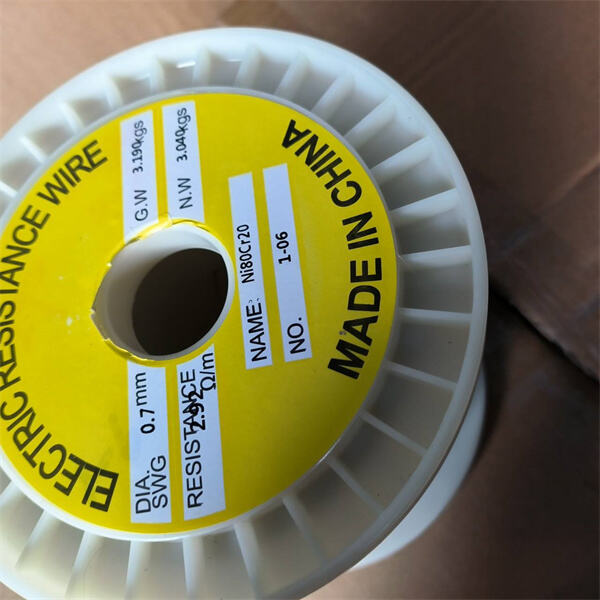

Heating wire is typically composed of resistive (low resistive material) material including nickel-chromium or kanthal, just like the Hastelloy created by DLX. They are formed into coils or ribbons to increase surface area and heat produced.

The heating wire technology is also bringing a lot of new thoughts and refinements in recent years, along with DLX's product ss316. Some heating wire systems, for instance, now have smart thermostats that can be controlled via a smartphone or tablet. It simplifies the management of heating systems. “Often, scientists are constantly working on improvements to heating wire efficiency and newly developed materials with higher temperature resistance and service life.”

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.