Inconel 718 Spring Wire for Extreme Temperature and High-Strength Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

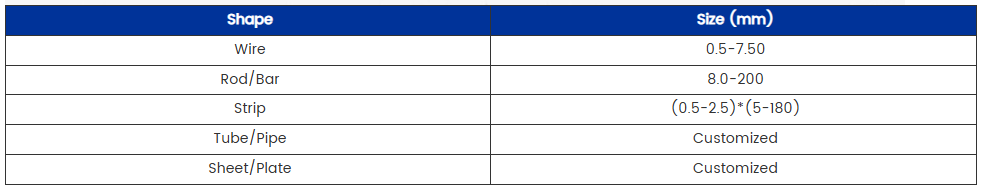

- Specification

- Applications

- FAQs

- Recommended Products

High tensile strength (up to 180 ksi/1240 MPa) even at elevated temperatures

Outstanding fatigue resistance with superior endurance limits

Maintains structural integrity from cryogenic conditions (-423°F/-253°C) up to 1300°F (704°C)

Excellent corrosion resistance against oxidizing and reducing media

Remarkable resistance to pitting and crevice corrosion

Stable performance in high-pressure, high-stress environments

Retains strength at temperatures where most steels weaken

Resistant to oxidation and carburization in high-temperature service

Performs reliably in acidic, alkaline, and saline environments

Good weldability compared to other superalloys

Age-hardenable for optimized mechanical properties

Available in various tempers (annealed, cold drawn, solution treated)

Jet engine components (compressor springs, turbine seals)

Aircraft structural springs (landing gear, flight control systems)

Spacecraft mechanisms operating in extreme thermal cycles

Downhole tool springs for high-pressure environments

Valve components in sour gas service (H₂S resistance)

Subsea equipment springs for deepwater applications

Nuclear reactor components (control rod drive mechanisms)

Gas turbine engine springs for power plants

Geothermal energy system components

Chemical processing equipment (pumps, valves, reactors)

Medical device springs requiring biocompatibility

High-performance industrial machinery components

Additive manufacturing of complex spring geometries

Precision wire forming for customized spring designs

Surface engineering for enhanced performance characteristics

Expanding aerospace sector (commercial and defense applications)

Energy industry evolution (renewables, nuclear, oil/gas)

Medical technology advancements requiring reliable components

Improved alloy formulations for enhanced properties

Advanced heat treatment processes for property optimization

Development of hybrid material systems combining multiple alloys

In the realm of high-performance engineering materials, Inconel 718 spring wire has established itself as a premier solution for applications demanding exceptional strength, corrosion resistance, and thermal stability. This nickel-chromium superalloy is specifically engineered to withstand extreme environments while maintaining superior mechanical properties, making it indispensable across aerospace, energy, and industrial sectors.

As technological advancements push operational boundaries into more demanding regimes, the need for reliable spring materials capable of performing under intense stress and temperature conditions continues to grow. This article provides a comprehensive examination of Inconel 718 spring wire, exploring its material properties, critical applications, and emerging industry trends that are shaping its use in modern engineering.

Material Properties and Advantages

1. Exceptional Mechanical Performance

2. Superior Environmental Resistance

3. Thermal and Chemical Stability

4. Manufacturing and Processing Benefits

Critical Applications

1. Aerospace and Defense

2. Oil and Gas Industry

3. Power Generation

4. Industrial and Medical

Emerging Industry Trends

1. Advanced Manufacturing Techniques

2. Growing Market Drivers

3. Material Science Innovations

Conclusion: The Future of High-Performance Spring Materials

Inconel 718 spring wire represents the cutting edge of spring material technology, offering unparalleled performance in the most demanding operational environments. Its unique combination of high strength, thermal stability, and corrosion resistance makes it an essential material for engineers facing extreme application challenges.

As industries continue to evolve and operational requirements become more stringent, Inconel 718 is poised to play an increasingly critical role in next-generation engineering solutions. Ongoing advancements in material science, manufacturing technologies, and application engineering ensure that this remarkable superalloy will remain at the forefront of high-performance spring materials for years to come.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

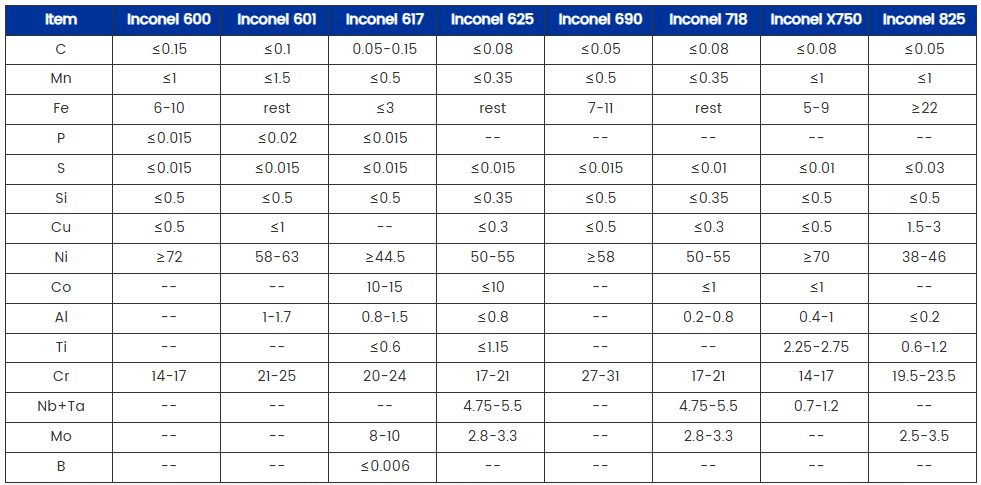

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.