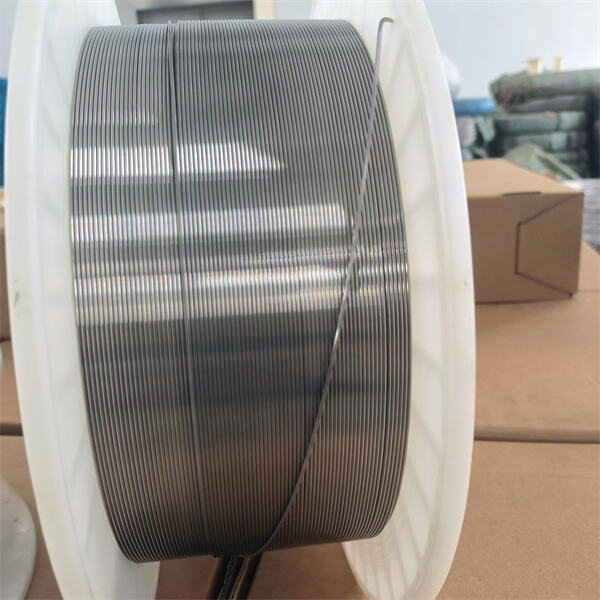

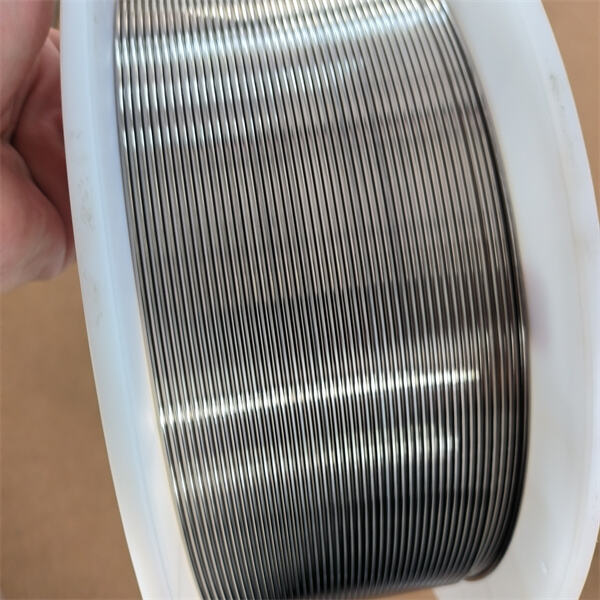

A special wire that is used to cover the metal surfaces to protect them is known as arc spray wire. More heat is applied to the wire with electricity, and the wire gets sprayed onto the metal. DLX resistance heating wire forms a thick layer that prevents rust and damage.

Arc spray wire is applied in several applications, including manufacturing, construction, and aerospace. Steel, aluminum, and copper are examples of metals on which it may be used. This is why DLX fecral wire is commonly used in companies that want to protect its tools and machines.

Using arc spray wire has one major advantage — DLX Thermal Spray Wire helps save a lot of money for some companies. One way is by coating metal surfaces with a thin layer of wire which improves machine life and reduces the need for repairs. So, for businesses that wish to save money while maintaining the tool's health, arc spray wire can be a viable option.

Arc spray wire coatings are both tough and long-lasting. When the wire touches, it adheres firmly to the metal, forming a barrier against rust and abrasion. DLX Thermocouple Series allows machines and tools to be in good working conditions for a longer time.

One more advantage to arc spray wire is that it increases the efficiency of companies. Companies can reduce the time they spend on repairs by preventing rust and damage on metal surfaces. This allows them to concentrate on their primary work and is more productive.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.