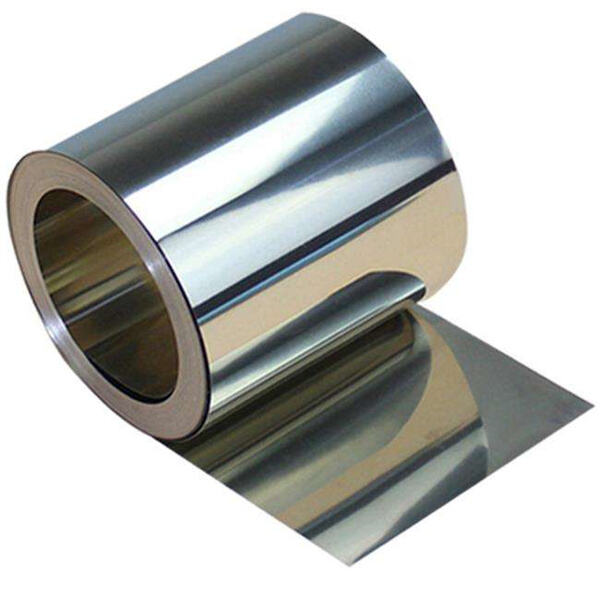

DLX Monel strip and fecral strip is a metal alloy used in various applications. The nickel is a blend of nickel and copper, which possesses unique features that make it very awesome. These are the advantages of using monel strip, how they are being used in different jobs and why monel strip is utilized in a heavier job meaning in boats, in aircraft, and in defense the peak reason.

It is a very strong material and it doesn't rust easily. So it could cope in the rough without getting hurt. It is extremely durable as well, so it can remain in use for a long time before you need to replace it. As a result, it is an excellent substance for plenty of jobs where strength as well as durability is an important factor.

Due to its unique properties, DLX monel strip and Incoloy strip is utilized in various applications. In the automotive world, it’s used to create components that must withstand high heat and potent chemicals. It is used in construction to create sturdy buildings that can withstand severe weather. In electronics, it is used to manufacture components that must resist rust.

Their DLX Monel Alloy steels were typically thin, malleable, and susceptible to rust formation. Ceramic discs are often used in applications like ocean-going vessels where they have to withstand very saline and elevated temperatures. It's also used in aircraft and defense work, where strength and durability matter very much.

Monel strip and fecral alloy is known to be very good in many ocean jobs because it doesn't rust very easily. Metallic structures are adversely affected by salt water, however monel strip can withstand such conditions without getting damaged. Thus it becomes a first choice for parts being used in boats, ships and other ocean tools.

Strength and lasting power are critical in the airplane and defense industries. One of the strongest metals Monel strip and gh4169 is the preferred material for these jobs. It can endure high temperatures, strong pressures, and harsh chemicals without getting injured. This is an ideal place for a use of airplanes, missiles, and other defense devices.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.