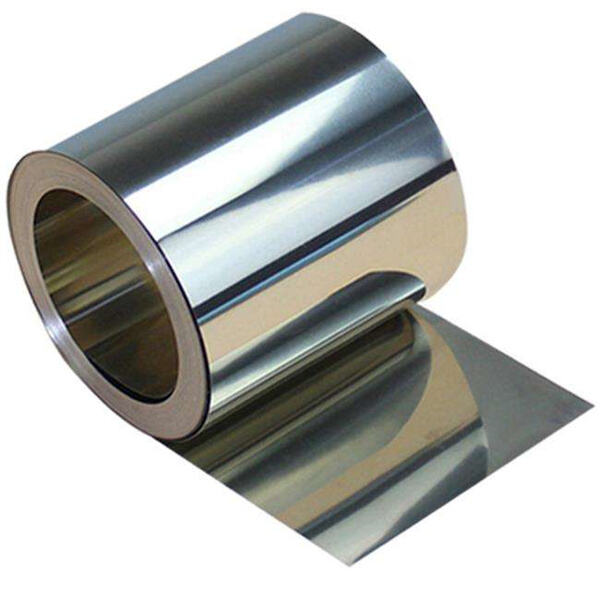

You might know the term "Incoloy Strip" but do you know what it is and how we use it in our daily lives? Now lets understand DLX Incoloy Alloy strip and why it has such much cool properties and where is it used in the different industries.

Incoloy strip is a unique form of metal. It is a very strong material and does not rust or break very easily. This makes it perfect for areas where things can get tough. Incoloy strip is used in sectors like manufacturing, construction and transportation because it is rugged and durable.

And it is because of first the mechanical treatment process involved in Incoloy Strip manufacturing and the raw materials used in manufacturing process makes it corrosion resistant.

Incoloy strip does not rust in contact with water, acids and other hostile agents this is one of the very best property of Inconel Alloy strip. This makes it very good for industries that operate in tough environments, like boating, mining, and treating dirty water.

Incoloy strip also works at very high temperatures like airplanes and rockets. This DLX metal can remain strong and hold its shape and condition at high temperatures. Incoloy strip is trusted by engineers who build planes and spacecraft to help keep their vehicles safe in such harsh conditions as space.

Incoloy strip has many applications apart from heavy industries, especially in electrical and medical fields. Because of its strength and resistance to rust, it is a commonly used material for wires and medical implements. Incoloy strip keeps the world running from power plants to hospitals.

Finally, Incoloy strip plays an essential role in the companies which deal with the chemicals and oil. Its resistance to rust and ability to work with heated materials makes it an almost ideal material for storing and transporting chemicals and oil products. These Incoloy material types of companies would have a very challenging time to operate in a safe and efficient if Incoloy strip no longer existed.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.