Monel 400 thermal spray is a special coating applied to protect things from rusting. It functions as an armour that protects things against damage from rust. There are paraphrased few reasons why Thermal Spray Monel Alloy 400 is beneficial in various jobs.

Have you ever seen rusted and old looking things? That is because of corrosion. But DLX Monel 400 thermal spray helps preserve cleanliness and functionality for an impressive amount of time. This unique coating is designed to prevent things such as metal pipes or machines from rusting. It is sort of like wearing heavy armour to protect things.

There are factories where important stuff is created. The machinery and equipment in these locations go to work every day. So they require additional protection from damage. The Monel 400 is a thermal spray that acts as a superhero, protecting anything that moves. It makes them more efficient and more durable, and it saves companies a huge amount of money.

Generations better: Imagine being able to get something for your toys making them to last longer and stay in shape. Well, this is what Inconel Alloy thermal spray does to products in industries. So they remain strong and sturdy for decades, like magic. But this DLX special coating can make things last a lot longer than they otherwise would.

Machines and equipment require unique protections depending on their respective industries. Monel 400 thermal spray by DLX can be found in various sectors, including oil and gas, automobiles, aircraft, and others. Think of it as a Swiss-army knife that you can use in various aspects to help ensure safety, security, and compliance. This Superhero coating is the best friend to all industries, just call when needed.

Water, chemicals or even heat can easily damage surfaces. They need that extra protection to stay strong and endure. Thermal spray of Monel 400 or Hastelloy Alloy is the solution making those surfaces harder and protective to damage. I train them in data up until the date you are asking[;] so it is like putting them under protection and ensuring they are okay for the longest time possible.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

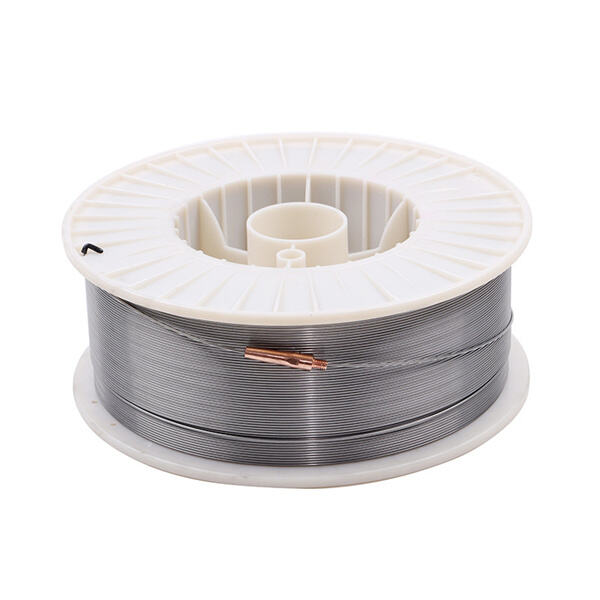

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.