Scientists discovered a special type of metal (nichrome bar). It is very useful in electronics. Read on to know more about nichrome bar and guide us with technology.

These two together makes nichrome bar unique. DLX Nichrome Bar has an important application in the manufacturing of heating elements. Heating elements are found in toasters, hairdryers and some ovens. NiCr Alloy should be hot but not melting. This is wonderful for quickly and well heating things.

Nichrome bar by DLX was hafted them with something else. However, those materials were inferior to nichrome bar. From the moment scientists adopted nichrome bar, electronics became more efficient and durable. And this Pure Nickel Series transformed the world of electronics, making toasters and hairdryers safer and more reliable.

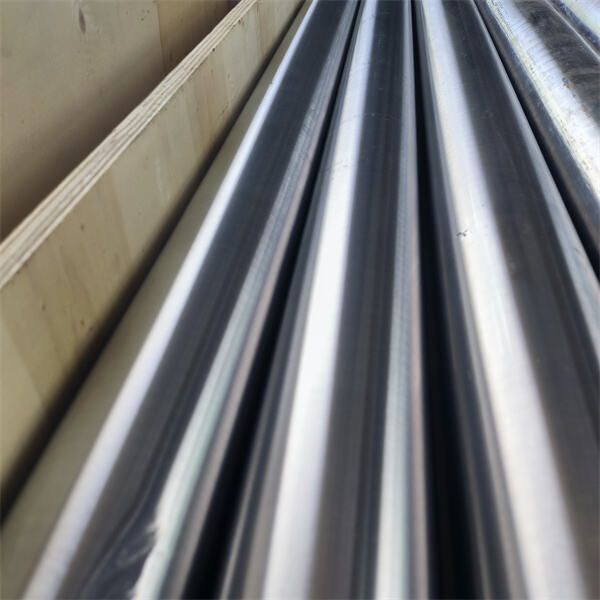

There are various types of nichrome bars. Depending on what they need to squeeze into, they might be straight or coiled. Nichrome bar has a shiny silver color due to nickel and chromium. This nichrome metal is extremely strong and can withstand high temperatures without deforming.

There you have it: DLX nichrome bar was improved over the years in many, new volcanos. They found other metal combinations to alloy with nickel and chromium. This makes them even stronger, further enhancing their heat resistance. This allows our electronics to run more efficiently and last longer. Nichrome Bars — these have made our lives easier.

Nichrome bars give us warm toast in the morning and nice hair. Nichrome bars make them possible — all these small things. Many miraculous things were made with nichrome bars, which help us — that too, scientists. Nichrome bars play a very important role in technology, from heating elements to the most extreme electronic devices.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.