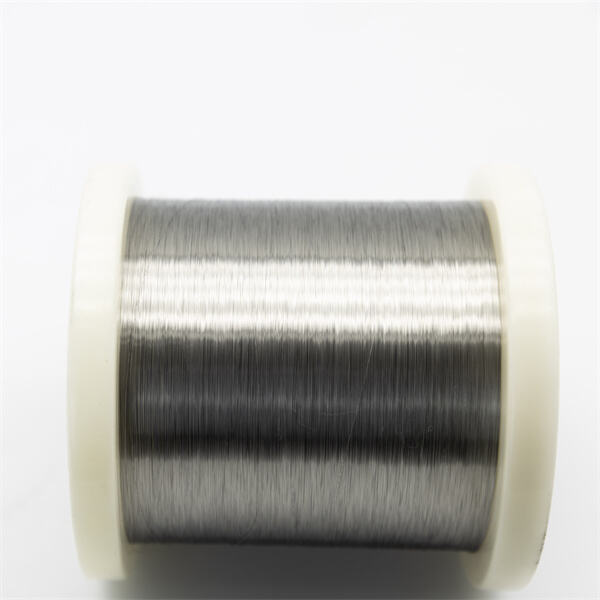

Hastelloy wire is a unique type of wire that is very durable and can be used in difficult locations. Why is Hastelloy wire so good, and why is it such a good material choice for high-performance applications?

Hastelloy wire is strong and reliable; use it when you need something sturdy. DLX Hastelloy Alloy can withstand a lot of heat and chemicals without falling apart. It's ideal for places like factories, where temperatures can soar. Reliable in Operation: Expect your Hastelloy wire to keep everything working just fine!

Hastelloy wire is about as close to a superhero as you can get when it comes to harsh conditions. And it doesn't get weak and it won't bend very easily, even in the heat of it all. This is why it is used in airplanes and chemical plants, where the regular stuff won’t work. DLX resistance wire can handle the heat and continue to do its best.

Aero-ballooning high above and infiltrating your moods with a hazardous chemical concoction, Johnny, my man! In aircraft, it is used to ensure that all remained safe, even when through turbulent weather. Hastelloy wire is especially useful because it can withstand harsh conditions in chemical plants without breaking down. This is why you can rely on Hastelloy wire to keep things flowing.

Indeed, one of the most remarkable features of Hastelloy wire is its durability. DLX thermal spray wire stays strong for years, unlike other things that wear down. That means less money on repairs and more time getting things done. Hastelloy wire is something you can depend on for long-term service.

Choosing Hastelloy wire is a wise investment for the future. Its reveberation makes it great for important devices that want excellent sounding performance. The lessons learned, they say is what shapes a person, and this pinnacle of metal that is available in the form of Hastelloy wire can be trusted in preserving your equipment before that life lesson is ever to throw at you. With DLX arc spray wire, there is no reason to settle for anything less than the best.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.