Nickel Chromium Wire Cr30Ni70 - Wear-Resistant for Aerospace

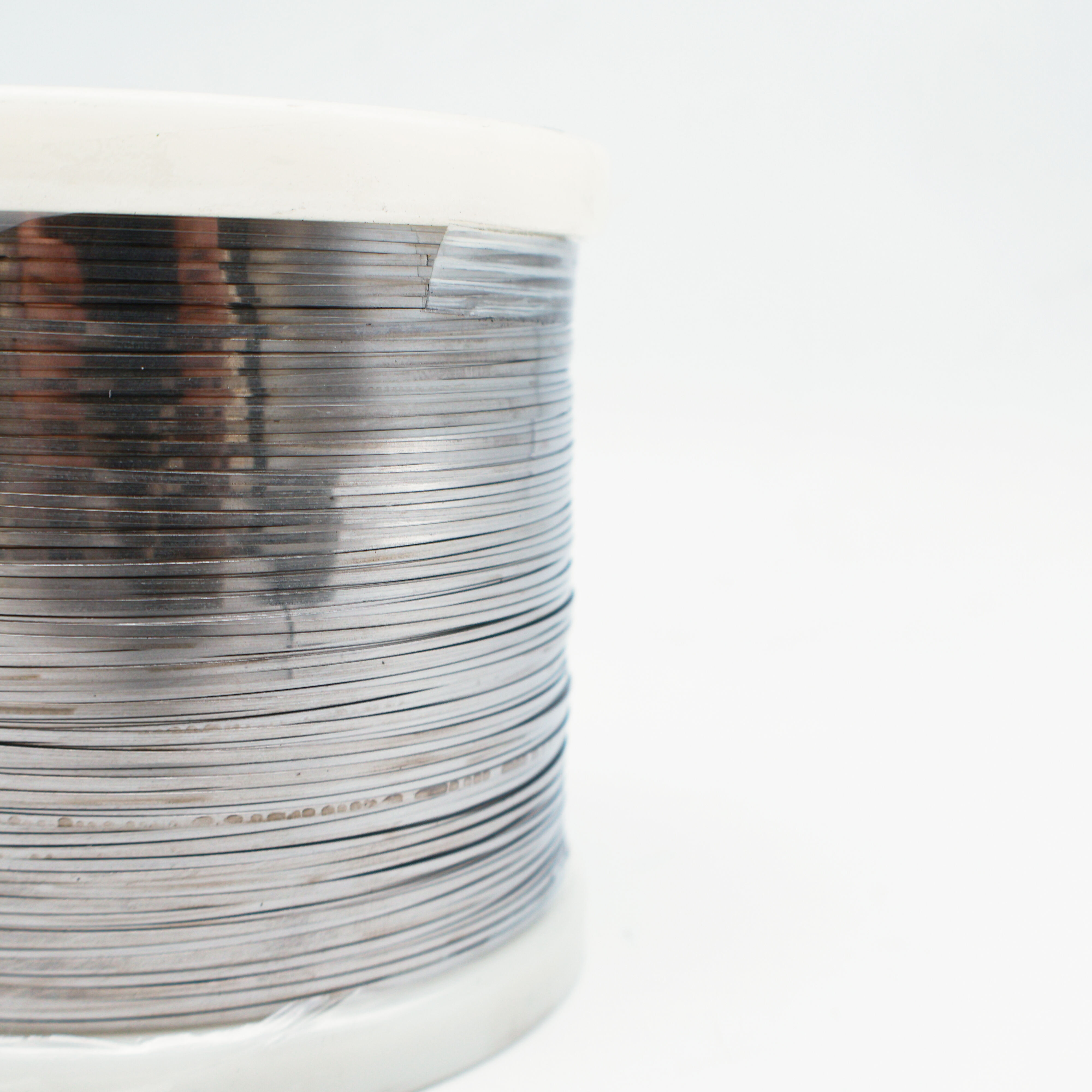

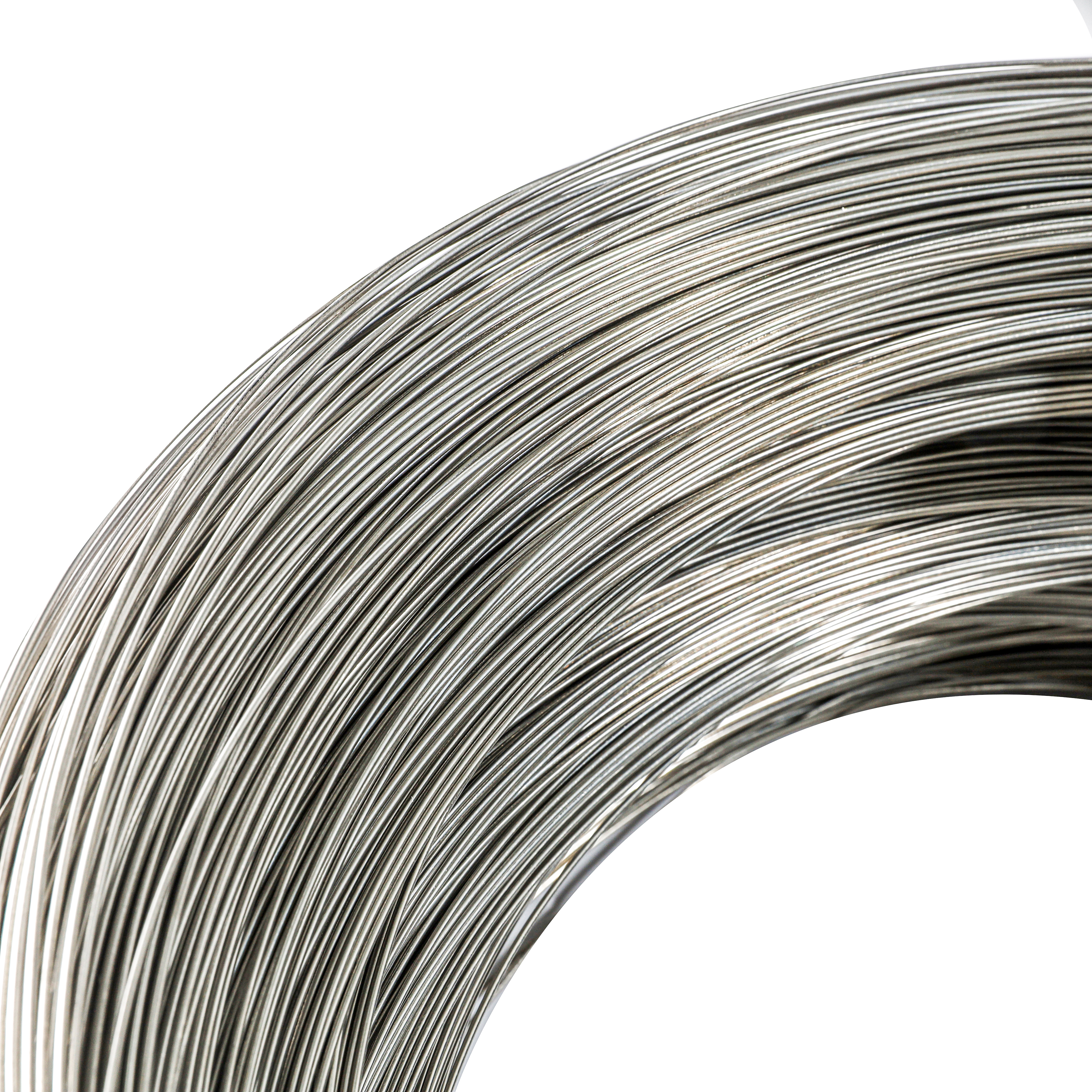

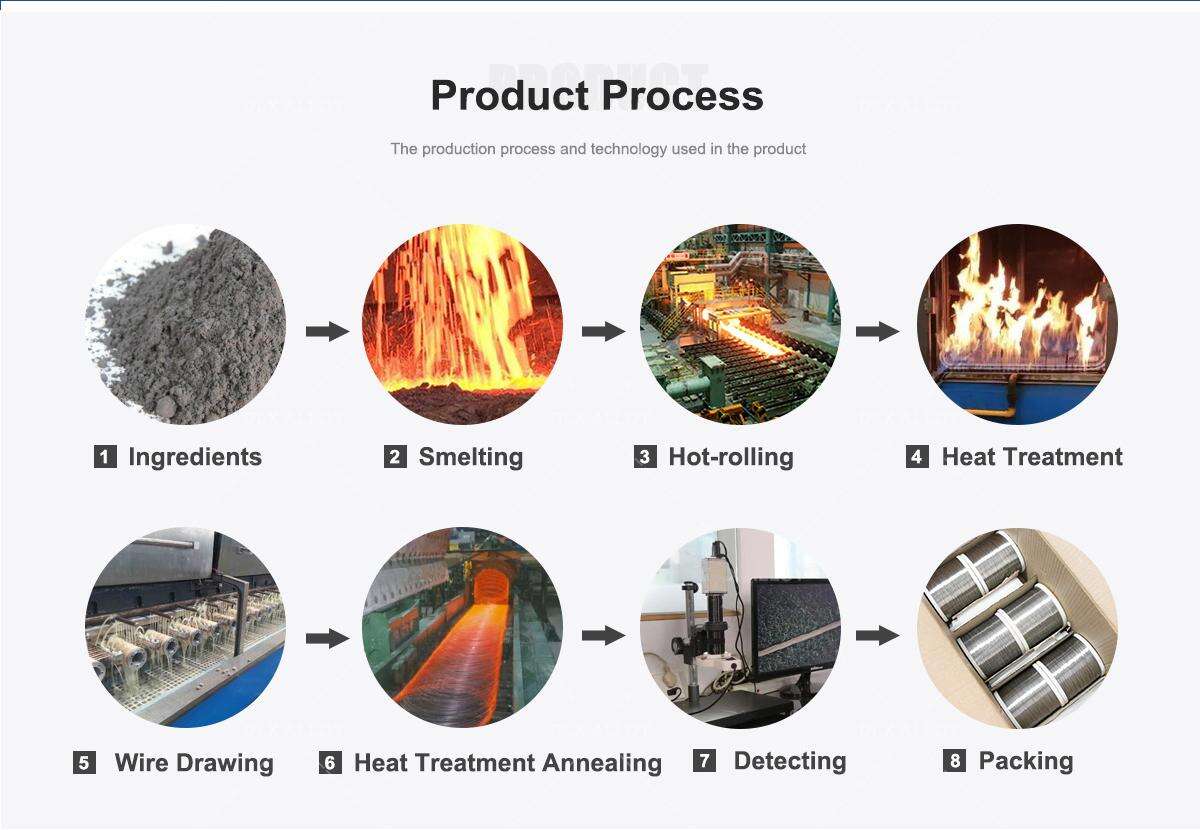

Discover the superior performance of Cr30Ni70 Nickel Chromium Wire, a premium nichrome alloy engineered for exceptional wear resistance and thermal stability. Ideal for demanding aerospace applications, this high-resistance wire offers unmatched durability in extreme conditions, making it a top choice for aerospace engineers seeking reliable nichrome heating elements and corrosion-resistant materials. With its precise Cr30Ni70 composition—30% chromium and 70% nickel—this wire excels in high-temperature environments, providing long-lasting performance against oxidation and mechanical wear.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- High-Temperature Stability in Nichrome Alloys: Withstands temperatures up to 1200°C without degradation, perfect for aerospace heating wire applications where thermal endurance is critical.

- Superior Wear Resistance for Aerospace Components: The Cr30Ni70 composition provides excellent mechanical strength and abrasion resistance, reducing wear in high-vibration aerospace environments like aircraft engines.

- Oxidation and Corrosion Resistance in Nichrome Wire: Chromium content ensures robust protection against oxidative atmospheres, making it ideal for long-term use in aerospace resistance heating elements.

- Optimal Electrical Resistivity for Heating Elements: Offers consistent resistivity (approximately 1.18 μΩ·m), enabling precise control in aerospace electrical systems and nichrome coil applications.

- Lightweight and Flexible Nichrome Alloy Design: Easy to form and integrate into complex aerospace structures, supporting efficient manufacturing of wear-resistant wire components.

- High Tensile Strength in Aerospace Nichrome Materials: Boasts tensile strength up to 700 MPa, ensuring reliability under stress in space-grade nichrome wire setups.

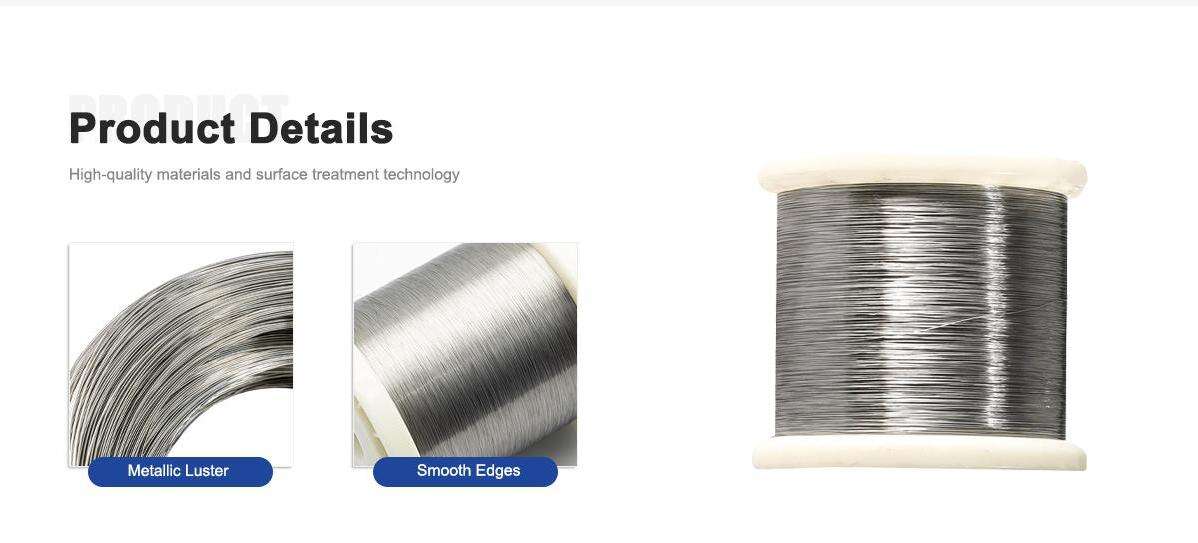

Cr30Ni70 Nickel Chromium Wire Overview:

Cr30Ni70 Nickel Chromium Wire stands out as a high-performance nichrome alloy specifically designed for aerospace wear resistance. This nichrome heating wire combines nickel and chromium in a 70:30 ratio, delivering exceptional high-temperature resistance up to 1200°C, making it indispensable for aerospace heating elements and structural components. As a versatile resistance wire, it offers superior oxidation resistance, electrical conductivity, and mechanical toughness, catering to the rigorous demands of aerospace engineering. From turbine parts to sensor assemblies, this Cr30Ni70 nichrome wire is engineered to withstand harsh environments, ensuring reliability in high-stakes aerospace projects. Explore how this aerospace nichrome alloy can elevate your designs with its proven track record in thermal management and wear-resistant applications.

Cr30Ni70 Nickel Chromium Wire Features:

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Cr30Ni70 Nickel Chromium Wire Applications:

- Aerospace Engine Components with Nichrome Heating Wire: Utilized in turbine blades and exhaust systems for its high-temperature wear resistance, enhancing aerospace engine efficiency.

- Aircraft Sensor and Wiring Systems Using Cr30Ni70 Alloy: Provides reliable electrical resistance in sensors and wiring harnesses, ensuring accuracy in aerospace navigation and control.

- Spacecraft Thermal Management via Nichrome Resistance Wire: Essential for heating elements in satellites and space probes, offering thermal stability in vacuum environments.

- Aerospace Manufacturing Tools with Wear-Resistant Nichrome: Employed in cutting and forming tools where durability against abrasion is key for precision aerospace fabrication.

- High-Temperature Furnaces in Aerospace Testing: Serves as heating coils in simulation chambers, replicating extreme conditions for aerospace material testing.

- Avionics and Electronics with Corrosion-Resistant Nichrome Wire: Integrates into electronic assemblies for its oxidation resistance, supporting reliable aerospace avionics performance.

- Drone and UAV Components Featuring Cr30Ni70 Nichrome Alloy: Enhances lightweight structures in unmanned aerial vehicles with superior wear and thermal properties.

Cr30Ni70 Nickel Chromium Wire FAQ:

1.What is Cr30Ni70 Nickel Chromium Wire and its role in aerospace applications?

Cr30Ni70 is a nichrome alloy wire with 30% chromium and 70% nickel, renowned for its wear-resistant properties in aerospace heating elements and high-temperature environments.

2.How does the wear resistance of Cr30Ni70 nichrome wire benefit aerospace engineering?

Its high chromium content provides exceptional abrasion and oxidation resistance, making it ideal for aerospace components exposed to mechanical stress and extreme heat.

3.What temperature range can Cr30Ni70 nickel chromium alloy wire handle in aerospace settings?

This nichrome resistance wire operates effectively up to 1200°C, ensuring reliability in aerospace thermal management and heating applications.

4.Is Cr30Ni70 nichrome wire suitable for corrosion-resistant aerospace materials?

Yes, its composition offers strong corrosion resistance, protecting against harsh atmospheric conditions in aerospace and space-grade projects.

5.How to select the right gauge for Cr30Ni70 nichrome heating wire in aerospace designs?

Choose based on required resistivity and application; finer gauges suit precise heating elements, while thicker ones provide enhanced durability for aerospace structural uses.

6.Can Cr30Ni70 nickel chromium wire be customized for specific aerospace nichrome alloy needs?

Absolutely, we offer custom lengths, diameters, and coatings to match your aerospace wear-resistant wire requirements.