Nickel Based Thermal Spray Wire Inconel 625 - Corrosion Resistant Alloy for Aerospace

Inconel 625 wire ensures long-lasting protection and enhanced component longevity. Available in various diameters for arc spray and flame spray systems, this corrosion resistant alloy wire meets stringent industry standards like AMS 5599 and ASTM B443.

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Inconel 625 Nickel Alloy Wire Overview:

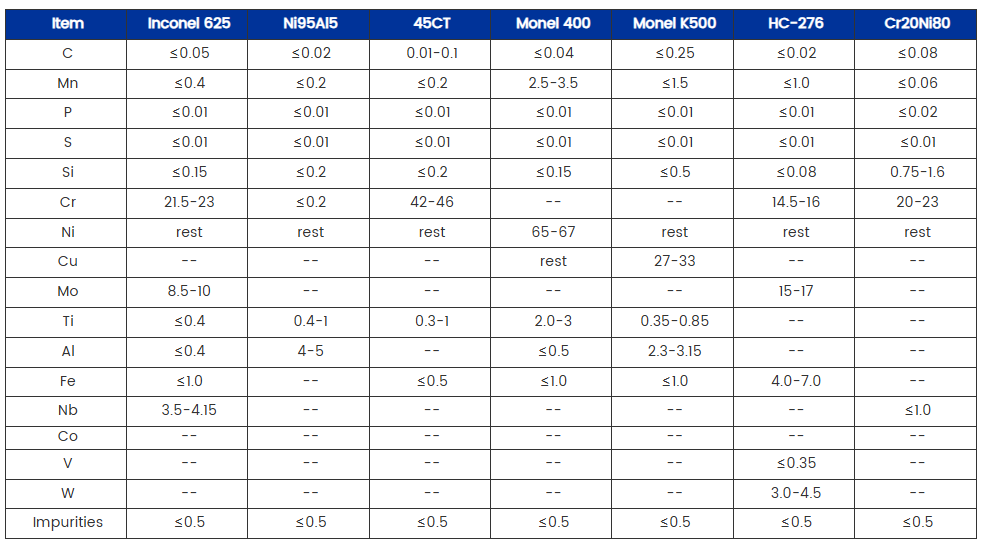

Inconel 625 is a renowned nickel based superalloy known for its outstanding resistance to corrosive environments, including seawater, acids, and alkalis. As a thermal spray wire, it is used to apply protective coatings via processes such as plasma spraying or HVOF (High-Velocity Oxy-Fuel), creating barriers that withstand extreme temperatures up to 980°C (1800°F). This alloy's unique composition, featuring high nickel content (58% min), chromium (20-23%), molybdenum (8-10%), and niobium (3.15-4.15%), imparts excellent mechanical properties like high tensile strength and fatigue resistance. Ideal for aerospace components, gas turbines, and oil & gas equipment, our Inconel 625 wire offers a cost-effective solution for extending service life in aggressive conditions. Whether you're in the USA, Europe, or Asia, this nickel alloy thermal spray wire supports global manufacturing needs with consistent quality and availability.

Inconel 625 Thermal Spray Wire Features:

- Superior Corrosion Resistance in Nickel Alloy Wire: Excels in resisting pitting, crevice corrosion, and stress corrosion cracking, making it perfect for harsh chemical and marine environments.

- High-Temperature Strength for Thermal Spray Coatings: Maintains structural integrity at elevated temperatures, ideal for aerospace turbine blades and exhaust systems.

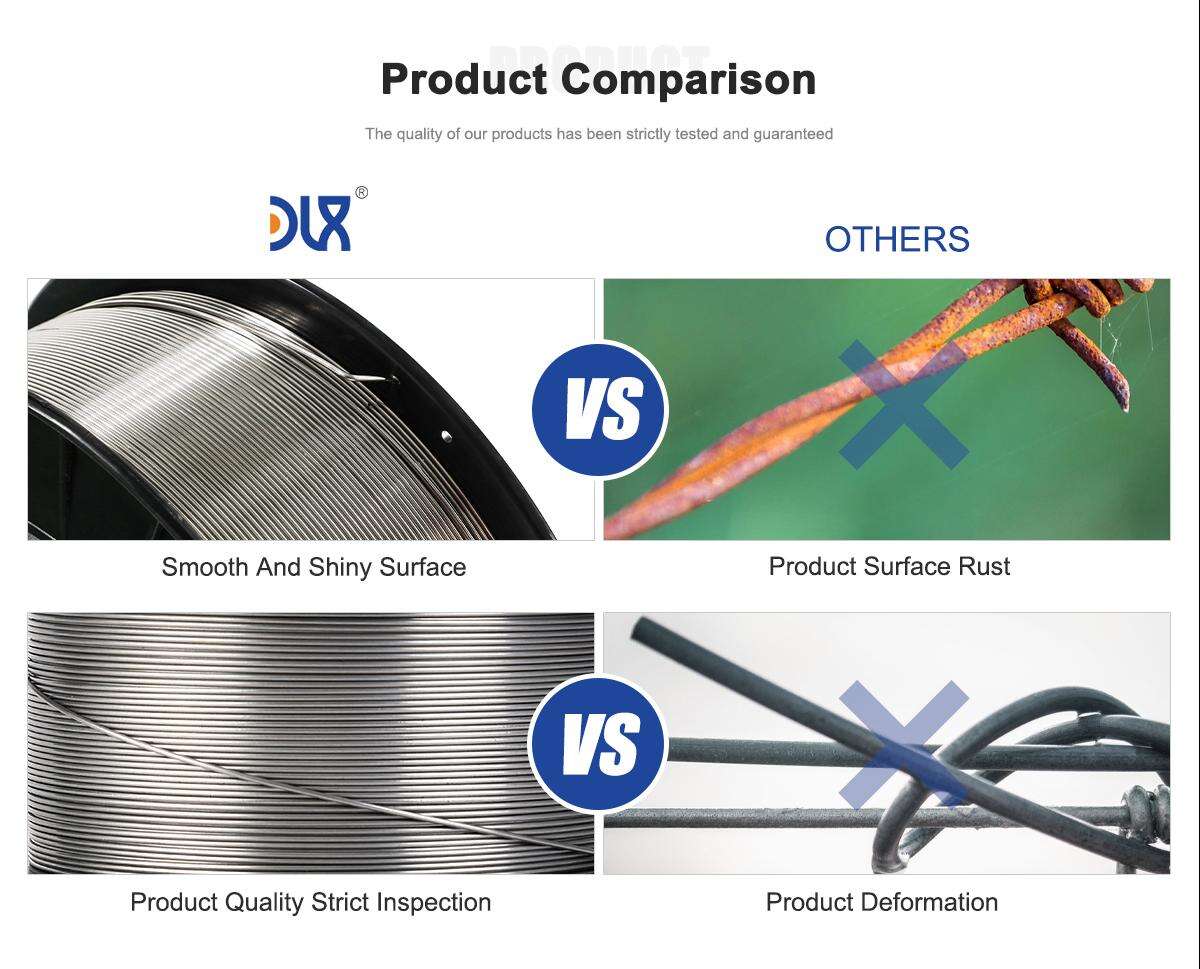

- Excellent Weldability and Formability in Inconel 625 Wire: Easy to apply via arc or flame spraying, ensuring uniform coatings with minimal porosity.

- Oxidation Resistance in Superalloy Thermal Spray Materials: Provides robust protection against oxidation and scaling in high-heat scenarios like power generation.

- Versatile Diameter Options for Corrosion Resistant Wire: Available in standard sizes from 1.6mm to 3.2mm, compatible with various thermal spray equipment worldwide.

- Compliance with Industry Standards for Nickel Based Alloys: Meets AMS 5599, UNS N06625, and ISO certifications for reliable performance in global markets.

Inconel 625 Nickel Alloy Wire Applications:

- Aerospace Engineering with Corrosion Resistant Coatings: Used for protecting turbine components, engine parts, and structural elements from high-temperature corrosion in aircraft and spacecraft.

- Marine and Offshore Applications for Nickel Based Wire: Ideal for coating ship hulls, offshore platforms, and subsea equipment to combat saltwater corrosion in regions like the Gulf of Mexico or North Sea.

- Chemical Processing Industry Thermal Spray Solutions: Applies to reactors, valves, and piping systems handling acids and alkalis in petrochemical plants across the USA and Middle East.

- Power Generation with High-Temperature Alloy Wire: Enhances boiler tubes and heat exchangers in nuclear and fossil fuel power stations for improved efficiency and durability.

- Oil and Gas Sector Corrosion Protection: Coats downhole tools and pipelines to resist sour gas and high-pressure environments in extraction sites worldwide.

- Automotive and Industrial Manufacturing Uses: Provides wear-resistant layers on exhaust manifolds and machinery parts for extended service in high-wear settings.

1.What is Inconel 625 thermal spray wire made of?

Inconel 625 is a nickel-chromium-molybdenum alloy with additions of niobium and tantalum, offering superior corrosion resistance and high-strength properties for thermal spray coating applications.

2.How does Inconel 625 wire provide corrosion resistance in aerospace?

Its composition resists oxidation and corrosive attacks from fuels, gases, and environmental factors, making it essential for aerospace components like jet engine parts in high-altitude operations.

3.What thermal spray processes are compatible with this nickel alloy wire?

It works well with arc spray, flame spray, plasma spray, and HVOF methods, ensuring versatile application for corrosion resistant coatings in various industries.

4.Where can I buy Inconel 625 thermal spray wire for global shipping?

Our products are available with worldwide shipping, including to major markets in the USA, Europe, Asia, and beyond, with options for bulk orders and custom specifications.

5.Is Inconel 625 nickel based wire suitable for high-temperature environments?

Yes, it maintains excellent mechanical properties up to 980°C, ideal for high-temperature alloy applications in gas turbines and heat exchangers.

6.What are the standard specifications for this corrosion resistant alloy wire?

It complies with AMS 5599, ASTM B443, and UNS N06625 standards, ensuring quality for aerospace and industrial thermal spray uses.