Medical Grade Titanium Rod Corrosion Resistant for Bone Fixation DLX

High-Performance Medical Grade Titanium Rods: Corrosion-Resistant Solutions for Orthopedic Bone Fixation Implants.Elevate your orthopedic procedures with our premium medical grade titanium rods, engineered for superior corrosion resistance and reliable bone fixation in demanding surgical environments.

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Overview: Comprehensive Guide to DLX Medical Grade Titanium Rods

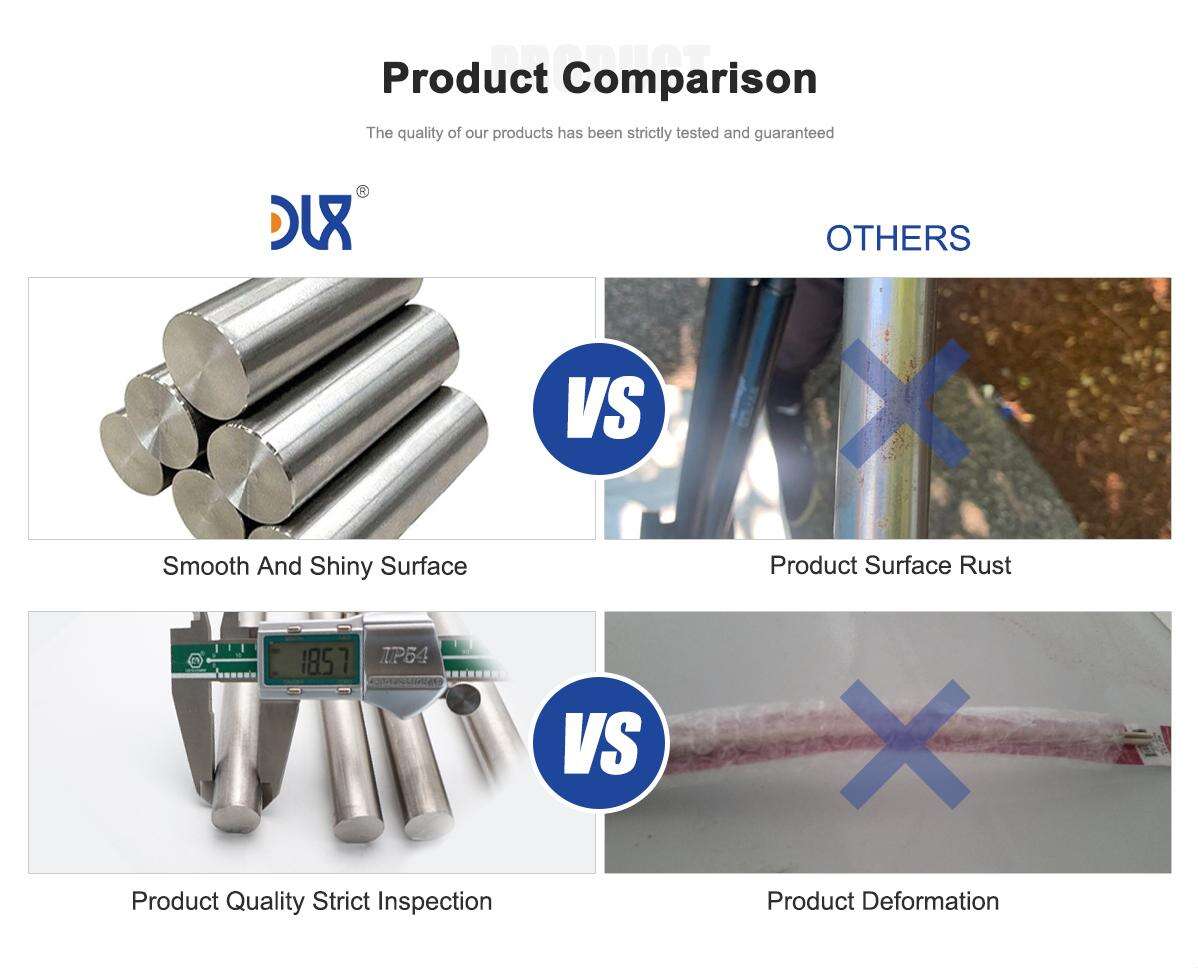

In the realm of biomedical engineering, our medical grade titanium rod represents the pinnacle of innovation for corrosion-resistant bone fixation solutions. These biocompatible titanium implants are essential for orthopedic professionals seeking reliable materials that withstand harsh physiological conditions. With a focus on titanium alloy rods for medical use, this overview highlights how our product excels in providing structural support for bone fractures, joint reconstructions, and trauma repairs. Backed by rigorous testing standards like ASTM F136, our surgical titanium bars ensure long-term performance, making them a preferred choice among global medical titanium suppliers for enhancing patient outcomes in bone repair and fixation procedures.

| DLX Titanium Rod Chemical Composition | |||||||||

| Grade | N | C | H | Fe | O | AL | V | Pa | Mo |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | ||||

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | ||||

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | ||||

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | ||||

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | ||

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.12-0.25 | |||

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | 0.2-0.4 | |

Key Features of Corrosion-Resistant Medical Titanium Rods

- Superior Corrosion Resistance in Biocompatible Titanium Alloys: Engineered to withstand harsh physiological environments, preventing degradation in bone fixation devices and orthopedic implants.

- High Strength and Lightweight Design for Surgical Titanium Rods: Offers excellent tensile strength while remaining lightweight, ideal for medical implant hardware and fracture repair systems.

- ASTM F136 Compliant Implant Grade Titanium: Meets international standards for biocompatibility, ensuring safe use in orthopedic surgery rods and bone repair applications.

- Machinable and Customizable Medical Titanium Supplies: Easily machined into various shapes for custom bone fixation implants, supporting diverse surgical needs in titanium medical devices.

- Non-Magnetic and Hypoallergenic Orthopedic Fixation Bars: Reduces interference in MRI scans and minimizes allergic reactions, perfect for long-term implant-grade titanium solutions.

Applications of Medical Grade Titanium Rods

1.Orthopedic Bone Fixation and Fracture Repair:

Utilized in plates, screws, and rods for stabilizing fractures, providing reliable support in bone repair hardware and surgical implants.

2.Spinal and Joint Reconstruction with Biocompatible Titanium Alloys:

Essential for spinal fusion devices and joint prostheses, enhancing stability in orthopedic surgery applications.

3.Dental and Maxillofacial Implants Using Surgical Titanium Bars:

Supports dental implants and facial reconstruction, leveraging corrosion resistant properties for long-term medical device performance.

4.Trauma Surgery and Emergency Bone Fixation Systems:

Ideal for quick-deployment orthopedic fixation devices in trauma cases, ensuring durability in high-stress medical environments.

5.Custom Medical Manufacturing with Implant Grade Titanium Rods:

Employed by manufacturers for prototyping and producing specialized titanium medical supplies for global healthcare providers.

1.What makes Grade 2 Titanium Rod suitable for medical implants?

Grade 2 titanium is highly biocompatible and corrosion-resistant, meeting ASTM F67 standards for safe use in human body applications like orthopedic and dental implants.

2.Is DLX Titanium Rod Grade 2 certified for global medical use?

Yes, our high purity titanium rods comply with ISO 5832-2 and other international regulations, ensuring suitability for medical device manufacturers in the USA, Europe, and beyond.

3.How does the corrosion resistance of Grade 2 Titanium compare to other grades?

Grade 2 offers excellent resistance to bodily fluids and chemicals, outperforming lower purity options in long-term biomedical environments for surgical grade titanium applications.

4.Can these titanium rods be customized for specific medical applications?

Absolutely, our machinable titanium bar stock allows for custom diameters and lengths, ideal for tailored orthopedic rods and prosthetic designs.

5.What are the storage and handling recommendations for high purity titanium rods?

Store in a dry, clean environment to maintain corrosion resistance; avoid contact with contaminants to preserve biocompatibility for medical implant production.

6.Are there any geographic restrictions on purchasing DLX Grade 2 Titanium Rods?

No, we ship worldwide, supporting medical suppliers in key regions like North America, Asia, and Europe with reliable titanium alloy materials.