High-Temperature DLX Ni95Al5 Thermal Spray Wire for Industrial

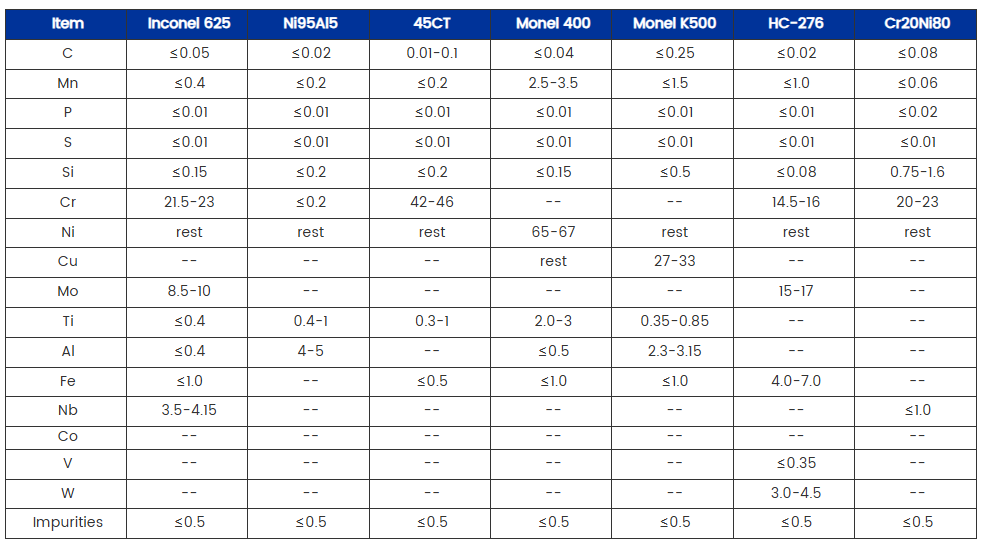

The DLX Ni95Al5 thermal spray wire is a high-performance nickel aluminum alloy (95% Ni, 5% Al) engineered for thermal spraying applications. Known as TAFA 75B or Metco 8400 equivalent, this wire provides exceptional bond strength, oxidation resistance, and corrosion protection in high-temperature settings.

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Ni95Al5 Thermal Spray Wire Overview:

In the realm of thermal spray materials, DLX Ni95Al5 stands out as a versatile nickel aluminum thermal spray wire tailored for industrial high-temperature applications. This alloy wire, composed of 95% nickel and 5% aluminum, excels in creating self-adhesive coatings that bond seamlessly to substrates without additional preparation. Commonly used in arc spray wire processes and flame spray techniques, it offers robust protection against oxidation, corrosion, and thermal cycling. Industries rely on Ni95Al5 for its reliability in harsh environments, such as turbine components and boiler systems, ensuring enhanced performance and reduced maintenance costs. With a density of approximately 8.2 g/cm³ and excellent electrical resistivity, this thermal spray alloy wire is a go-to solution for professionals seeking durable, high-temperature resistant coatings.

Essential Features of High-Temperature Resistant Ni95Al5 Alloy Thermal Spray Wire for Arc Spraying

- Superior Bond Strength in Nickel Aluminum Thermal Spray Wire Applications: Provides self-bonding capabilities, ensuring strong adhesion to metals without primers, ideal for industrial coating restoration.

- High Oxidation and Corrosion Resistance for Thermal Spray Alloy Wire: Withstands temperatures up to 1450°C, protecting against heat-induced degradation in arc spray and flame spray environments.

- Dense Coating Formation in Ni95Al5 Thermal Spray Wire Processes: Creates compact, low-porosity layers that resist thermal shock and abrasion, enhancing longevity in high-temperature industrial settings.

- Anti-High Temperature and Anti-Corrosion Properties in Alloy Spray Wire: Engineered for extreme conditions, offering reliable performance in sectors like aerospace and power generation.

Key Industrial Applications of Ni95Al5 Thermal Spray Wire for Oxidation and Wear Protection

- Turbine Blades and Hot-Surface Components in High-Temperature Thermal Spray Applications: Applies protective bond coats to prevent oxidation and extend service life in aerospace and energy industries.

- Boiler Tubes and Heat Exchangers for Corrosion-Resistant Thermal Spray Wire Use: Enhances resistance to high-temperature corrosion, ideal for power plants and chemical processing facilities.

- Wear-Resistant Coatings on Bearings and Machinery Parts with Ni95Al5 Alloy Wire: Restores dimensions and provides abrasion protection in manufacturing and heavy machinery sectors.

- Dimensional Buildup and Repair in Industrial Arc Spray Wire Projects: Used for rebuilding worn surfaces on valves, pumps, and structural components to minimize downtime.

- Anti-Skid and Protective Layers in Flame Spray Wire Applications: Offers surface enhancement for safety and durability in transportation and infrastructure environments.

1.What is Ni95Al5 thermal spray wire used for in industrial high-temperature applications?

Ni95Al5 thermal spray wire, also known as TAFA 75B, is primarily used for creating bond coats and protective layers in arc spraying and flame spraying. It provides excellent adhesion, oxidation resistance, and corrosion protection for components like turbine blades, boiler tubes, and machinery parts in high-heat environments.

2.How does DLX Ni95Al5 alloy wire perform in arc spray systems for corrosion protection?

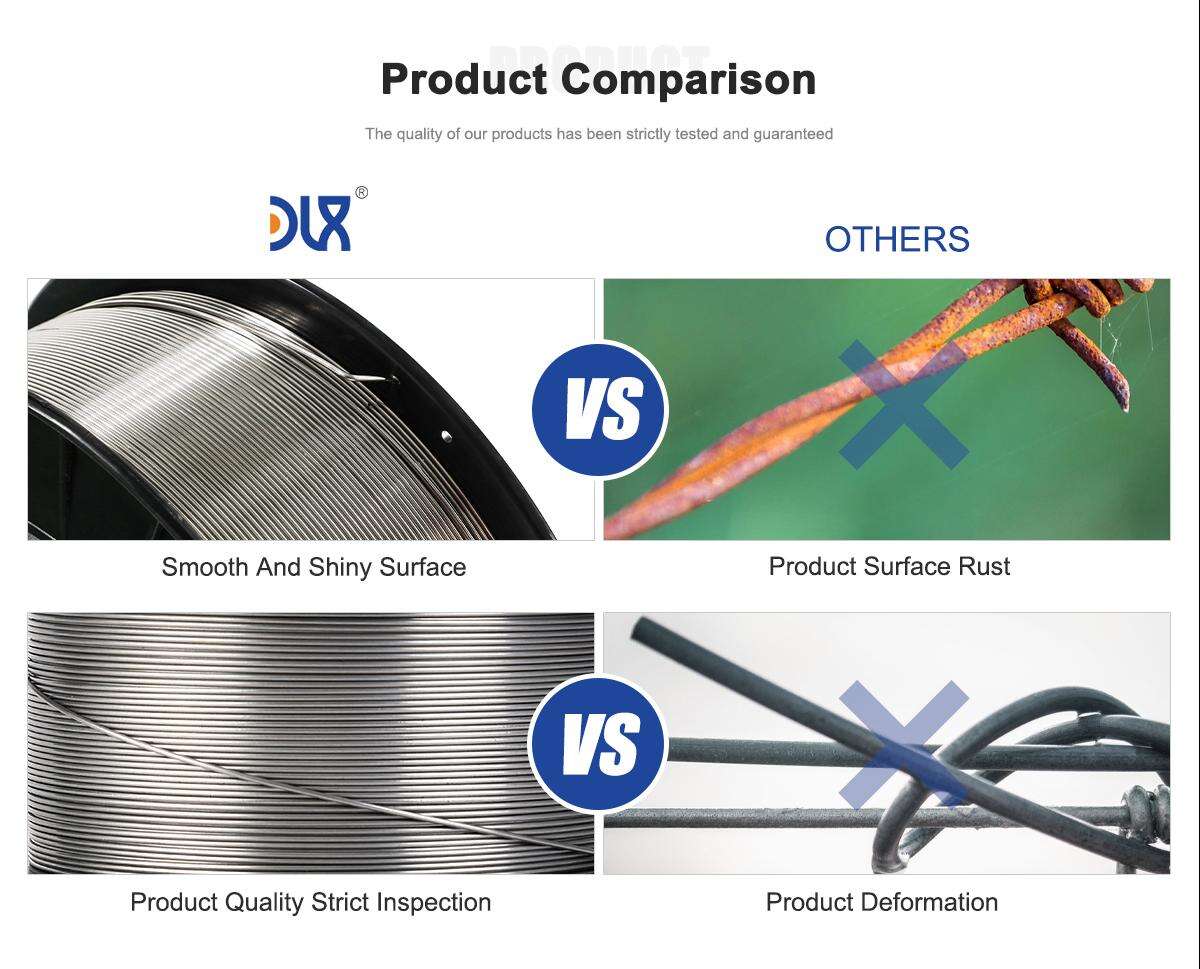

In arc spray systems, DLX Ni95Al5 wire melts to form dense, self-bonding coatings that excel in corrosion and high-temperature resistance. Its nickel aluminum composition ensures strong substrate adhesion and durability, making it suitable for industrial repairs and preventative maintenance.

3.Can Ni95Al5 thermal spray alloy wire be used for wear-resistant industrial coatings?

Yes, Ni95Al5 is highly effective for wear-resistant coatings in thermal spraying. It restores worn surfaces on bearings, pumps, and other parts, offering abrasion resistance and extending component life in demanding industrial settings.

4.What advantages does DLX Ni95Al5 offer over other thermal spray wires in high-temperature environments?

DLX Ni95Al5 provides superior self-bonding, thermal shock resistance, and versatility in both arc and flame spray methods. Its anti-corrosion and high-temperature capabilities make it a preferred choice for industrial applications where reliability and performance are critical.