High-Performance CuNi1 Alloy Profiles for Marine Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

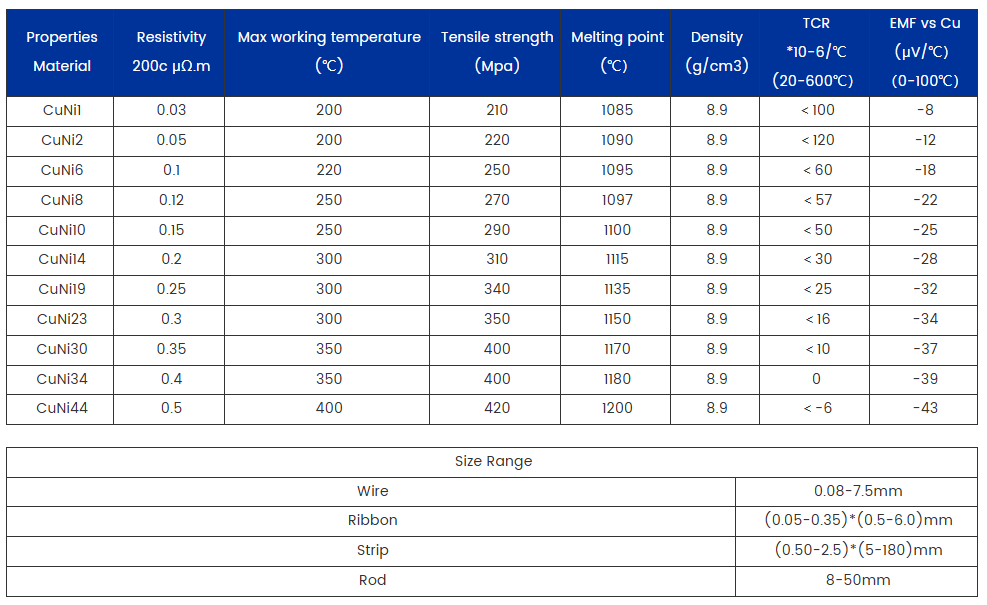

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

- Corrosion Resistance: CuNi1 alloy exhibits superior resistance to corrosion, especially in seawater, due to its nickel content. This makes it ideal for use in marine environments, where the presence of salt and other chemicals can degrade traditional metals.

- Strength and Durability: The alloy maintains its mechanical strength even in harsh conditions, providing a long service life for components made from it.

- Thermal Conductivity: CuNi1 offers moderate thermal conductivity, making it suitable for heat exchangers and other components requiring efficient heat dissipation.

- Biocompatibility: CuNi1 is compatible with marine life, making it safe for use in environments where organisms are present, such as in cooling systems of ships or marine platforms.

- Ease of Fabrication: The alloy is easy to form, weld, and machine, offering flexibility for manufacturers who need to create intricate parts for marine use.

-

Shipbuilding and Marine Vessels: CuNi1 alloy is commonly used in the construction of ships and marine vessels, including components like propellers, hulls, and piping systems. Its corrosion resistance ensures that parts exposed to seawater do not suffer from rapid deterioration, providing extended operational lifespans.

-

Marine Heat Exchangers: One of the most significant applications of CuNi1 is in marine heat exchangers. In these systems, the alloy is used to transfer heat between two fluids while preventing corrosion from saltwater. This is essential in systems like cooling systems for engines or other marine machinery.

-

Offshore Platforms: Offshore oil and gas platforms rely heavily on CuNi1 alloy for the construction of subsea structures, risers, and other parts that are exposed to the corrosive effects of seawater. The alloy’s resistance to biofouling and corrosion in extreme environments ensures the longevity of these vital components.

-

Marine Piping Systems: CuNi1 is used in various types of piping systems, including those found in desalination plants, power stations, and ships. The alloy’s ability to resist corrosion under high pressure and saltwater conditions ensures the reliable transport of fluids and gases, reducing the risk of system failure.

-

Water Treatment Systems: In marine water treatment systems, CuNi1 alloy is used for the construction of heat exchangers, condensers, and other components that are in constant contact with seawater. The alloy helps prevent corrosion and scaling, which can otherwise lead to system inefficiencies and costly repairs.

-

Subsea Cables and Connectors: CuNi1 alloy is also used in subsea cables and connectors due to its excellent electrical conductivity and corrosion resistance. These components are essential for the transmission of power and data between offshore structures and the mainland.

-

Corrosion Resistance: Users in the marine sector are looking for materials that resist corrosion in seawater. CuNi1 alloy, with its corrosion-resistant properties, meets this need by ensuring that parts exposed to saltwater do not degrade over time, ensuring fewer replacements and repairs.

-

Durability: Marine environments are challenging for materials, with constant exposure to saltwater, extreme weather, and physical stress. CuNi1 provides the necessary mechanical strength and resistance to wear and tear, making it an ideal material for durable marine components.

-

Environmental Impact: As industries become more conscious of their environmental impact, materials that prevent biofouling and reduce harm to marine life are in high demand. CuNi1’s ability to resist biofouling makes it a sustainable option for underwater applications.

-

Economic Efficiency: While CuNi1 is more expensive than some other materials, its extended service life and low maintenance costs make it a cost-effective solution in the long run. Users demand alloys that balance initial investment with long-term durability and performance.

-

Customization: Users often require materials that can be fabricated into specific shapes, sizes, and designs. CuNi1 is highly versatile and can be processed into various profiles, rods, bars, and tubes, allowing for easy customization to meet the needs of specific marine applications.

CuNi1 alloy, a copper-nickel alloy with a small percentage of nickel, is known for its excellent corrosion resistance, particularly in seawater environments. Composed of 99% copper and 1% nickel, this alloy strikes a balance between excellent conductivity and exceptional resistance to corrosion, making it an ideal material for various marine applications. CuNi1 is highly resistant to rust, pitting, and stress corrosion, which are common challenges when metals are exposed to saltwater conditions.

The CuNi1 alloy is often chosen for its ability to maintain both mechanical and physical integrity even when exposed to harsh marine environments. It also provides good weldability and is commonly used for products that require long-lasting durability in seawater. Its resistance to biofouling, which occurs in underwater structures, further increases its appeal in marine-related industries.

Key Properties of CuNi1 Alloy

Applications of CuNi1 Alloy in the Marine Industry

User Needs and Demands

The primary demand for CuNi1 alloy in the marine industry is driven by the need for reliable and long-lasting materials that can withstand the harsh conditions of the marine environment. The following user requirements have shaped the demand for CuNi1 alloy:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.