Innovative 4J33 Alloy Tubes for Superior Thermal Performance in Industrial Systems

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- About Us

- FAQs

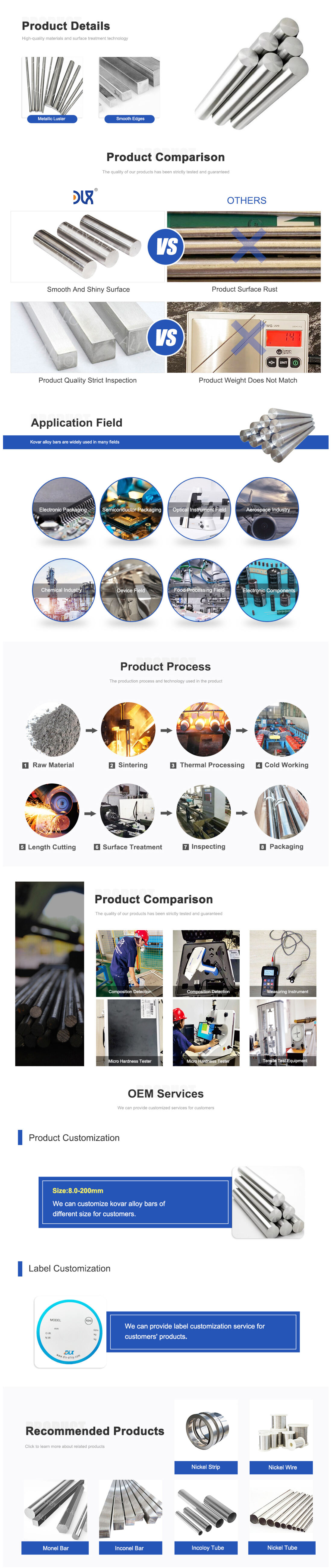

- Recommended Products

-

Industrial Heat Exchangers

One of the primary applications of 4J33 alloy tubes is in industrial heat exchangers, where the material’s ability to maintain thermal stability under extreme temperature conditions is paramount. These tubes are used to efficiently transfer heat between fluids in processes such as chemical reactions, oil refining, and power generation. Due to 4J33’s low CTE, it minimizes the risk of thermal expansion and contraction, ensuring that heat exchangers maintain their integrity even under continuous temperature fluctuations. This enhances the reliability and efficiency of heat exchange processes, ensuring the smooth operation of industrial systems. -

Chemical Processing Equipment

In chemical processing plants, materials are subjected to both high temperatures and harsh chemicals. 4J33 alloy tubes are highly resistant to corrosion and thermal expansion, making them ideal for use in reactors, distillation units, and cooling systems. Their ability to withstand extreme conditions while maintaining dimensional accuracy helps prevent system failures and ensures the efficiency of critical chemical processes. The high thermal conductivity of 4J33 alloy ensures that heat is effectively managed in complex chemical systems, contributing to the overall performance and safety of the equipment. -

Power Generation and Nuclear Reactors

The power generation industry, especially in nuclear reactors, demands materials that can handle extreme temperatures while maintaining structural integrity and reliability. 4J33 alloy tubes are highly suitable for these environments due to their thermal stability and resilience under high-pressure and high-temperature conditions. The alloy’s low thermal expansion ensures that the tubes perform efficiently during thermal cycles, preventing unwanted stresses that could lead to material fatigue. This makes 4J33 alloy an excellent choice for critical components in nuclear reactors, boilers, and heat exchangers in power plants, where performance and safety are non-negotiable. -

Oil and Gas Industry

The oil and gas industry also benefits from 4J33 alloy tubes, particularly in applications that involve high temperatures and pressure. These tubes are used in piping systems, drilling equipment, and refining processes, where thermal efficiency is crucial. The thermal stability and corrosion resistance of 4J33 alloy ensure that it maintains its structural properties under extreme conditions, thereby improving the longevity and performance of systems used in oil extraction, transportation, and refining. -

Aerospace and Defense Applications

Aerospace and defense industries require materials that can withstand high temperatures, extreme environmental conditions, and the rigors of continuous use. 4J33 alloy tubes are widely used in these sectors for their superior thermal performance and dimensional stability. In jet engines, propulsion systems, and rocket components, 4J33 alloy ensures heat management, minimizing the risk of component failure due to temperature fluctuations. Its low CTE also helps prevent material expansion, ensuring that complex aerospace systems function optimally in extreme conditions. -

Thermal Stability and Low CTE

The primary demand from industries using 4J33 alloy tubes is thermal stability. In environments where equipment must withstand high or fluctuating temperatures, 4J33 alloy’s low coefficient of thermal expansion (CTE) ensures that materials do not distort, crack, or warp under thermal stress. This feature is critical in industries like chemical processing, oil and gas, and aerospace, where thermal performance directly affects operational efficiency and safety. The material’s ability to retain its form under temperature fluctuations means that equipment experiences less wear and tear, resulting in reduced downtime and maintenance costs. -

Corrosion Resistance

Industrial systems, especially those in the chemical processing and oil and gas industries, often encounter corrosive substances that can degrade materials over time. Users of 4J33 alloy tubes require corrosion resistance to ensure that their equipment remains operational for extended periods without succumbing to environmental stressors. 4J33’s ability to resist oxidation and corrosion extends the service life of critical components, reducing the need for frequent replacements and enhancing the reliability of systems. -

Strength and Durability

In industrial settings, strength and durability are vital characteristics. 4J33 alloy tubes meet these demands by offering high mechanical strength while maintaining their properties in extreme operating conditions. This makes them well-suited for high-pressure systems, boilers, reactors, and other equipment that requires materials capable of withstanding significant physical stress without failure. The alloy’s inherent strength ensures the long-term performance of these systems, which is especially important in industries where equipment failure can result in costly downtime or safety hazards. -

Energy Efficiency

As industries continue to focus on energy efficiency, the thermal properties of materials like 4J33 alloy are becoming increasingly valuable. The superior heat conductivity of 4J33 ensures that energy transfer is efficient, leading to energy savings and more sustainable operations. Whether used in heat exchangers or power generation systems, 4J33 alloy tubes help minimize energy loss, contributing to the overall efficiency and cost-effectiveness of industrial processes. -

Cost-Effectiveness and Longevity

The cost-effectiveness of 4J33 alloy comes from its ability to maintain its structural and thermal properties over long periods of time. Because of its durability, industrial systems experience fewer maintenance and replacement costs, which directly translates to better return on investment (ROI). The material’s long-lasting performance ensures that users don’t have to replace parts as frequently, reducing both operational and maintenance expenses over the lifecycle of the equipment.

4J33 is a nickel-iron alloy renowned for its excellent thermal performance, particularly in applications requiring high levels of dimensional stability and resistance to thermal expansion. The unique properties of 4J33 alloy, including its low coefficient of thermal expansion (CTE) and thermal stability, make it an ideal material for use in industrial systems where reliable, consistent performance is crucial. Whether in power generation, chemical processing, or manufacturing, 4J33 alloy tubes offer the strength and durability needed to handle high-temperature environments and demanding operational conditions.

Due to its versatility and superior thermal characteristics, 4J33 alloy is increasingly used in a variety of industries, helping to enhance performance, reduce maintenance costs, and ensure long-term reliability.

Applications of 4J33 Alloy Tubes

User Demands and Requirements

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

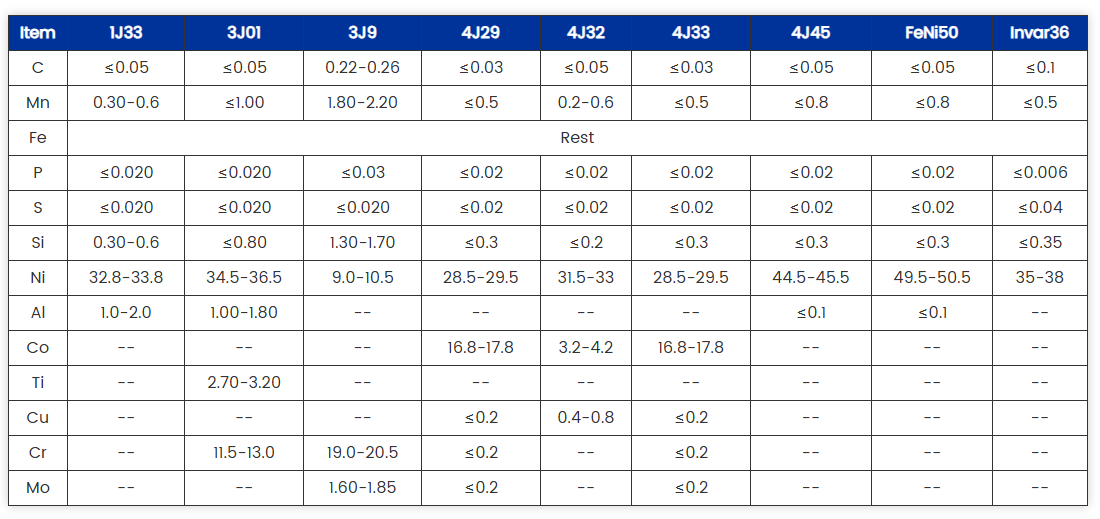

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.