DLX has you covered when it comes to nickel tape! Nickel tape is useful material that is used in many various jobs. Join us as we explore how nickel tape is revolutionizing electronics, cars, and beyond.

Nickel tape, just like a superhero, is your friend for electronics! Its ubiquitous in many electronics, from smartphones to computers. Nickel tape is so popular because it conducts electricity very nicely. It makes interconnections of various components in devices. So, if you have your favorite electronic gadget in your hands, keep in mind: some nickel tape might be making it work!

But nickel tape does not limit itself to this! It's also important in cars. It is also an important tool that helps cars function and testosterone. For instance, nickel tape is included in batteries of electric cars that enables these cars to store and deliver power. That helps cars to run better, and it is good for the environment. More eco friendly cars! (Thanks to nickel tape)

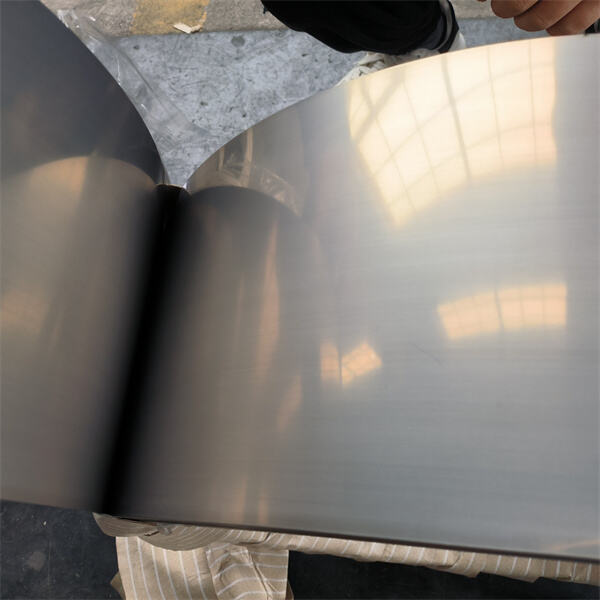

Nickel tape is used in many industries because it conducts electricity very well. But what does conductivity mean — it sounds all fancy and technical — what does it mean? Nickel tape is excellent at this, which is why so much of it’s used in electronic devices. DLX pure nickel welding rod tape is low-loss, low-power consumption, reliable, and efficient compared to other materials.

Nickel tape works well for packaging, too! It is also strong, able to withstand the bumps of shipping. This is why it is so great for shipping packages in a way that keeps them secure. So the next time you receive a package in the mail, take a look inside — you may find DLX nickel wire tape keeping it all together!

Nickel tape has a lot of applications outside of electronics and cars. This can be found with space travel, telecommunications, and energy. Nickel tape is used for electrical connections, such as in space travel. For telecommunications, it aids the performance of cables and wires. And nickel tape is critical in power production and distribution in energy. DLX Pure Nickel Series tape is a handy dandy little material keeping everything moving no matter the job.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

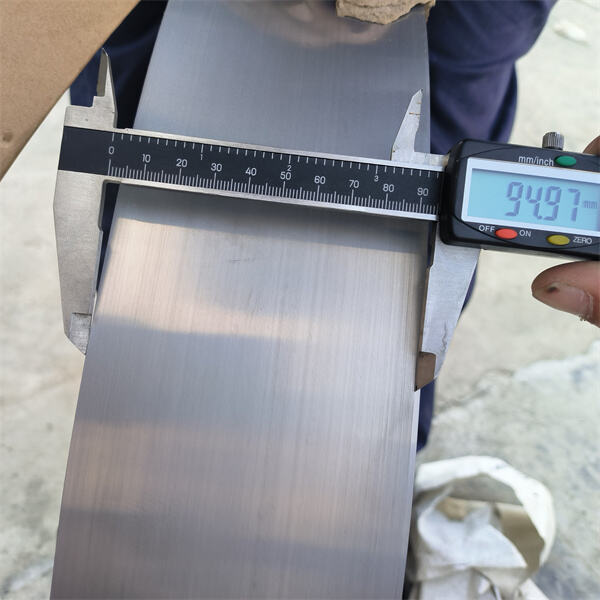

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.