There is a lot of great things about DLX nickel plated steel strip that make it favorite for the makers. A principal virtue is that it is solid as a rock and wears like iron, so it tolerates a lot of use. This makes it ideal for items that need longevity, like cars or kitchen appliances.

Nickel plated steel strip does not rust easily also which is another good thing. Which is what makes it perfect for outdoor furniture or boats, where it can get wet and face tough outdoors. Nickel plated steel strip and Monel Alloy is also easy to clean, which makes it a practical choice for many uses.

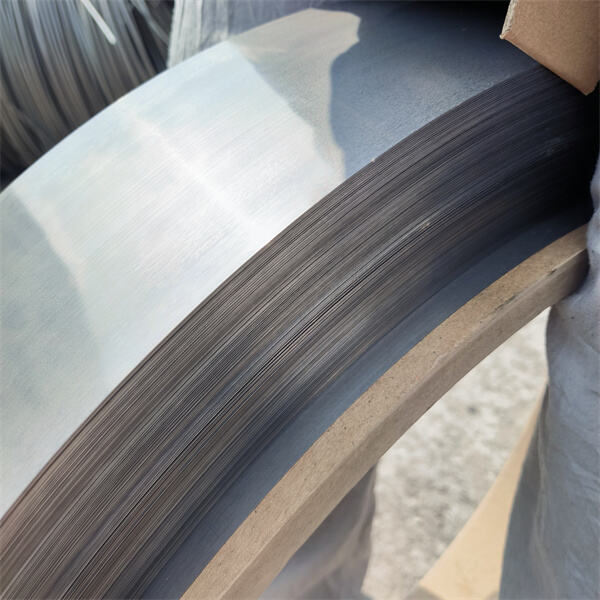

Nickel coated steel strip is very versatile material can be used in so many applications. You can bend, shape and cut it to fill an almost any need, making it a favorite of makers who are looking for something that would transform easily for whatever project that they are working on.

Nickel plated steel strip of DLX may further be coated with different materials to add additional properties, such as heat resistance or improved strength. All of this Incoloy Alloy means it is an excellent option for things that must perform well in adverse conditions or in high use. The versatility offered by nickel plated steel strip makes it an excellent option for a wide range of different industries.

Nickel plated steel strip is a strong and tough base material that helps the products last longer. Products manufactured with nickel plated steel strip are less likely to break or wear out as quickly which means that in the long run they can save people a lot of money.

It is also used in building applications for nickel plated steel strip, which creates tough and long living components. It is also used in the manufacture of parts in airplanes and other vehicles that need to be light and reliable. Generally speaking, DLX Pure Nickel Series is very important to manufacture all sorts of products which are used daily.

In summary, the use of nickel plated steel strip is a versatile option that provides several advantages to both makers and customers. Its strength, toughness, and flexibility make it an ideal choice for many industries, and in terms of making products last longer, it can save companies money in the long run.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.