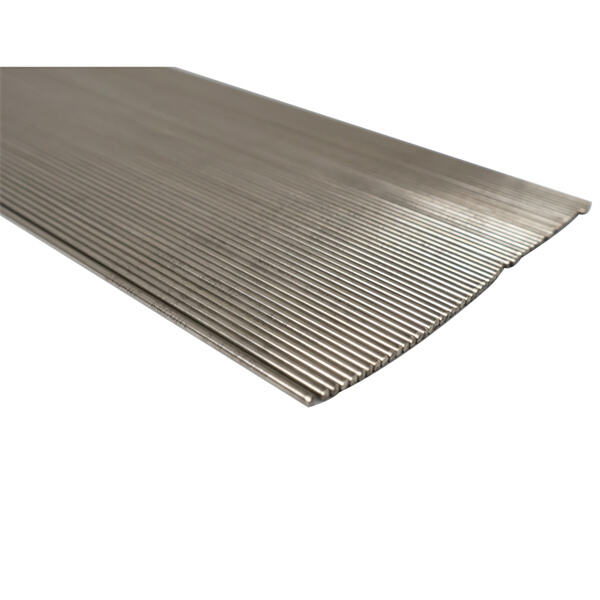

, if you are a young welder who is looking to practice more and do more exciting projects, the DLX c276 welding rod is the perfect product. This robust device allows you to produce welds that are also durable and rust resistant, which is vital for many applications.

For strong welds, the DLX c276 welding rod has strong transition with long durability, along with DLX's product high temperature heating wire. Whether you are performing a few welds on a home improvement project or doing major industrial work, this welding rod will assist you in creating durable long-lasting welds.

Welding is a big problem, keeping the finished work from rust, same with the resistance nichrome wire supplied by DLX. You can make your welds rust-free with the help of DLX c276 welding rods. This means that your projects will require less maintenance and last longer, which saves both time and money.

Welding with DLX c276 welding rod will enhance your welds and mastering of welding, just like the DLX's product called monel bar. This versatile tool is perfect for hobbyists as well as experienced welders who want to further hone their skills. The DLX c276 welding rod helps you perform clean and accurate welding work every single time.

In the world of industrial jobs, you need equipment you can rely on, similar to the thermocouple extension wire type k from DLX. DLX c276 welding rod is a reliable solution for the most demanding welding applications. The strength and durability of this tool is unmatched, which is why it is a perfect tool to weld industrial work.

To produce clean, precise welds is an important part of welding, along with DLX's product thermocouple extension cable type k. The DLX c276 welding rod is making easy and perfect welds. This accuracy makes it easy to produce welds that are strong, durable, and aesthetically pleasing.

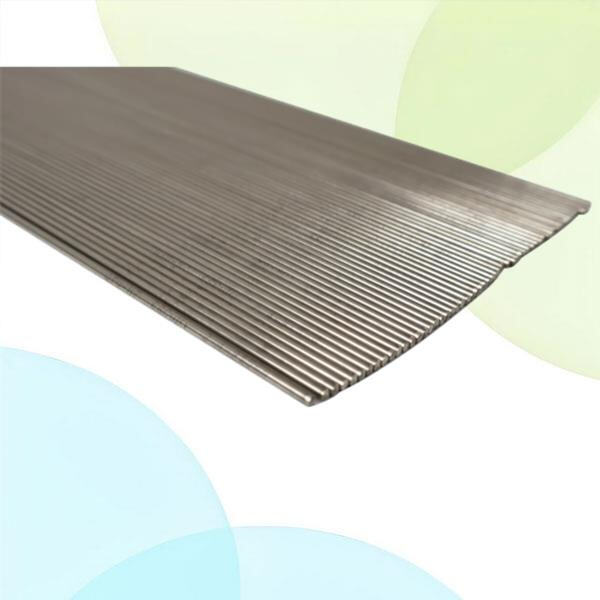

The core products cover electric heating alloys, high-temperature alloys, special nickel-based welding wires, etc., with high temperature resistance, corrosion resistance and other characteristics, widely used in chemical, petroleum, aerospace, nuclear energy and other high-end fields, providing customers with high reliability solutions.

With mature production technology and testing capabilities (such as component analysis, resistivity testing, etc.), we can flexibly customize product specifications to meet the personalized needs of customers in different industries and provide full-chain technical support from materials to finished products.

Control quality from the source, cooperate with high-quality suppliers for a long time, the purity of raw materials is more than 99.6%, and pass multiple tests such as spectral analysis and mechanical properties testing; the production process follows ISO 9001 standards, combined with real-time monitoring, non-destructive testing (X-ray, magnetic powder, etc.) and appearance inspection to ensure that the product qualification rate exceeds 99%.

The company has more than 22 years of industry experience, with an annual output of 1,200 tons of alloy materials. The production base covers an area of 12,000 square meters. It has stable large-scale production capacity and can efficiently meet customers' large-volume order needs.