Shape Memory Titanium Wire Superelastic for Medical

High-Performance Nitinol Superelastic Shape Memory Alloy Wire for Biocompatible Medical Devices

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

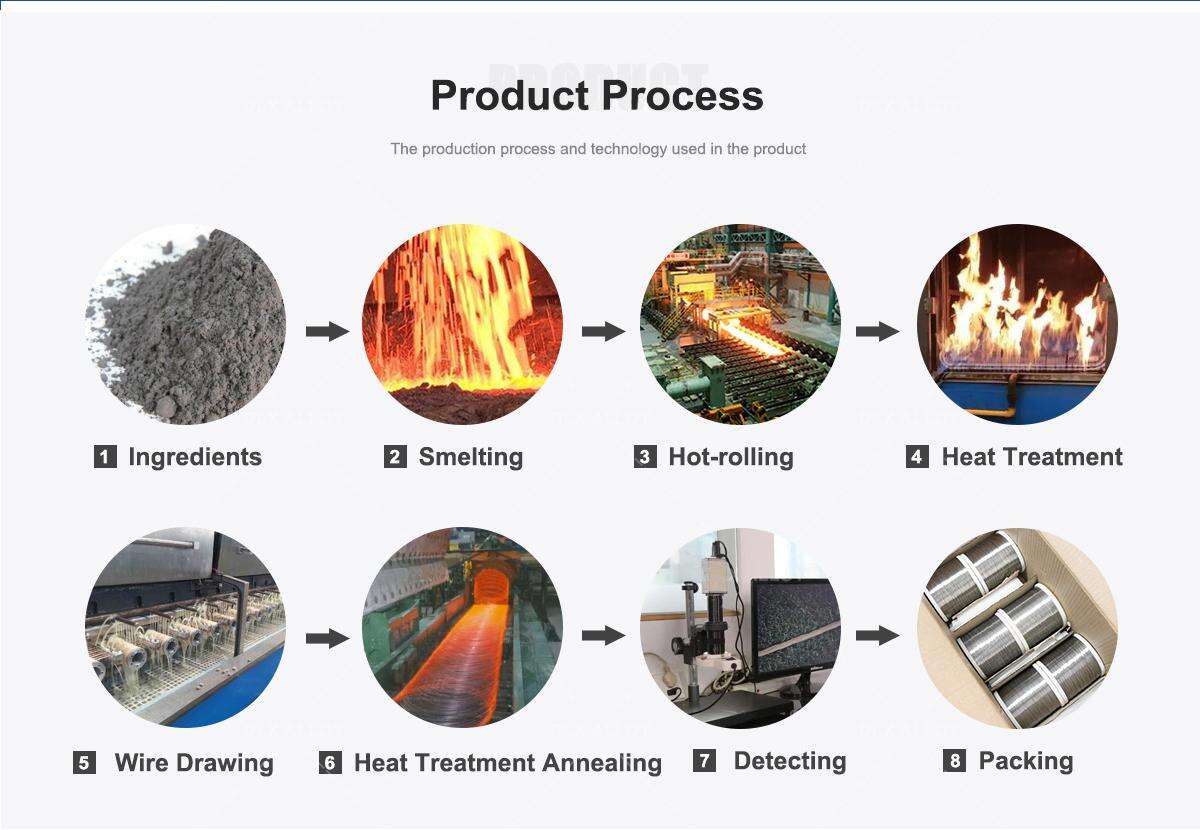

Nitinol Shape Memory Titanium Wire Description

Our Shape Memory Titanium Wire Superelastic for Medical is a cutting-edge nickel titanium alloy (Nitinol) designed to revolutionize medical device manufacturing. This biocompatible wire exhibits exceptional shape memory effect and superelasticity, allowing it to return to its original form after deformation, even under extreme conditions. Ideal for minimally invasive procedures, this medical-grade titanium nickel wire offers superior fatigue resistance, corrosion resistance, and biocompatibility, making it a top choice for healthcare professionals worldwide. Whether you're developing stents, guidewires, or orthodontic tools, this superelastic Nitinol wire ensures reliable performance in demanding medical environments, enhancing patient outcomes with its pseudoelastic properties and thermal shape memory capabilities.

| Grade 1 Titanium Wire Chemical Composition | |||||||||

| Grade | N | C | H | Fe | O | AL | V | Pa | Mo |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | ||||

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | ||||

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | ||||

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | ||||

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | ||

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | 0.12-0.25 | |||

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | 0.2-0.4 | |

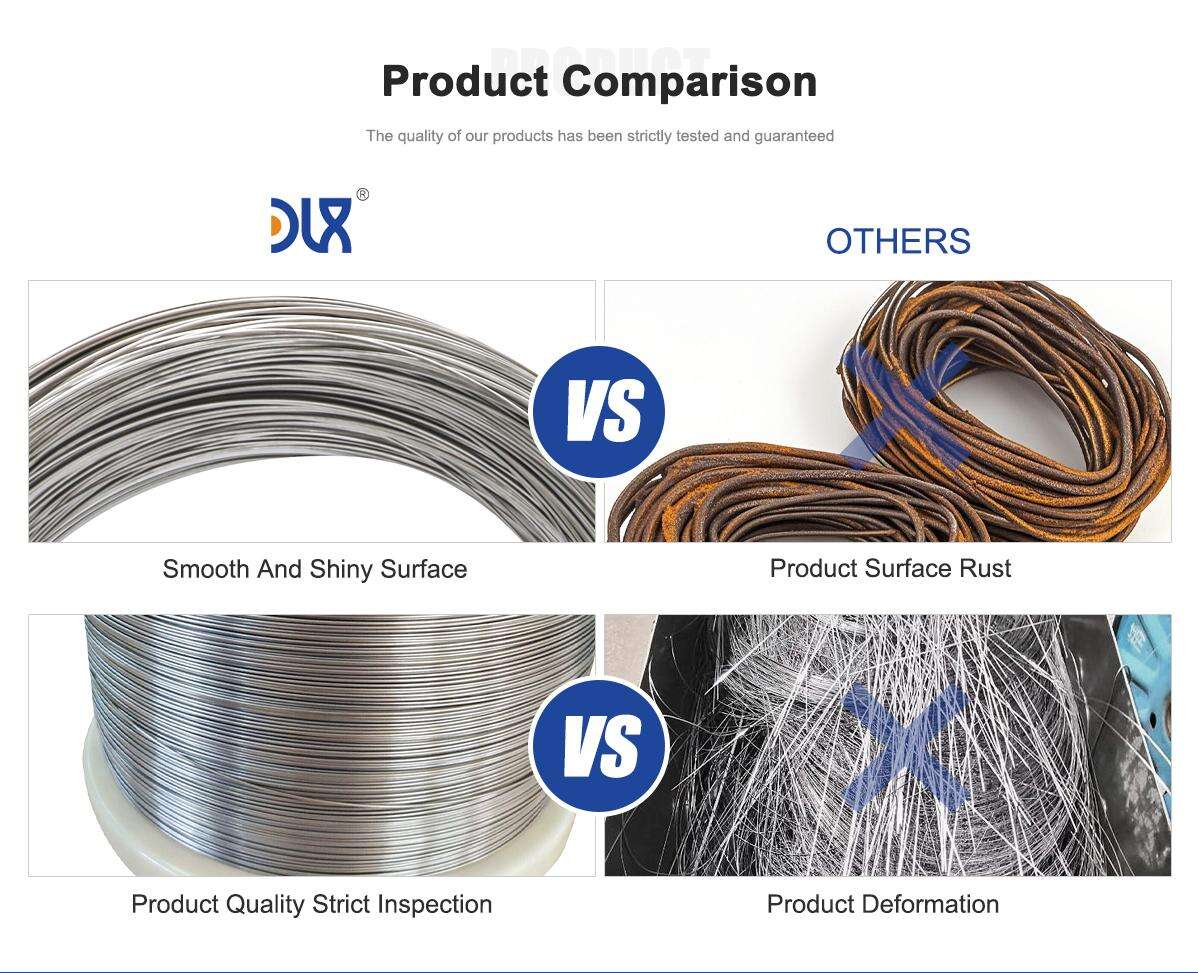

Nitinol Superelastic Wire Features

- Exceptional Superelasticity in Nitinol Wire: Allows up to 10-30% deformation without permanent damage, ideal for flexible medical instruments like catheters and guidewires.

- Shape Memory Effect for Titanium Nickel Alloy: Returns to predefined shape when heated above transformation temperature, enabling self-expanding medical devices such as stents and filters.

- Biocompatible Medical-Grade Titanium Wire: Features a stable oxide layer that minimizes nickel leaching, ensuring safety for long-term implants and reducing allergic reactions.

- High Fatigue and Corrosion Resistance in SMA Wire: Withstands millions of cycles in dynamic environments, perfect for orthopedic and cardiovascular applications.

- Customizable Transformation Temperatures in Superelastic Nitinol: Adjustable austenite finish (Af) from -20°C to +110°C for precise control in body-temperature responsive medical tools.

- Lightweight and High Strength Titanium Alloy Wire: Density of 6.45 g/cm³ combined with yield strength up to 690 MPa, offering durability without added weight in minimally invasive surgery equipment.

Superelastic Shape Memory Wire Applications: Medical Uses of Nitinol Titanium Nickel Alloy

- Vascular Stents and Filters with Nitinol Wire: Self-expanding designs for treating aneurysms and preventing embolisms, leveraging superelastic properties for easy catheter delivery.

- Orthodontic Archwires and Braces Using Shape Memory Alloy: Provides constant gentle force for teeth alignment, reducing adjustment frequency and patient discomfort.

- Guidewires and Catheters in Minimally Invasive Procedures: Superelastic flexibility allows navigation through complex anatomies in endovascular and urological interventions.

- Surgical Instruments and Endoscopic Tools with Titanium Nickel Wire: Enables precise, shape-recovering components for laparoscopic and robotic surgery.

- Orthopedic Implants and Bone Anchors via Biocompatible SMA Wire: Supports fracture fixation and spinal corrections with fatigue-resistant, body-adaptive materials.

- Neurovascular Devices Including Embolization Coils: Utilizes shape memory for targeted deployment in stroke treatment and aneurysm coiling.

1.What is Nitinol wire and how does its shape memory effect work in medical applications?

Nitinol wire is a nickel titanium alloy (SMA) that exhibits shape memory, allowing it to deform at lower temperatures and recover its original shape when heated to its transformation temperature (e.g., body heat). In medical devices, this enables self-expanding stents that compress for insertion and expand in the body for optimal fit.

2.What makes superelastic Nitinol wire suitable for biocompatible medical devices?

Superelasticity in Nitinol allows large deformations (up to 10-30 times more than standard metals) with immediate recovery, combined with biocompatibility from its titanium oxide layer, making it ideal for implants like guidewires and orthodontic tools without causing adverse reactions.

3.How do transformation temperatures affect the use of shape memory titanium nickel alloy wire in healthcare?

Transformation temperatures (e.g., austenite start As and finish Af) can be customized from -20°C to +110°C. For medical use, they're often set near body temperature (37°C) to trigger shape recovery in vivo, enhancing applications in vascular and orthopedic interventions.

4.What are the key advantages of using superelastic shape memory alloy wire over traditional materials in medical instruments?

Nitinol offers superior fatigue resistance, corrosion protection, and pseudoelasticity compared to stainless steel, reducing breakage risks in dynamic tools like catheters and enabling minimally invasive designs that improve patient recovery times.