Precision-Made Inconel 718 Spring Wire for Aerospace Fasteners and Springs

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

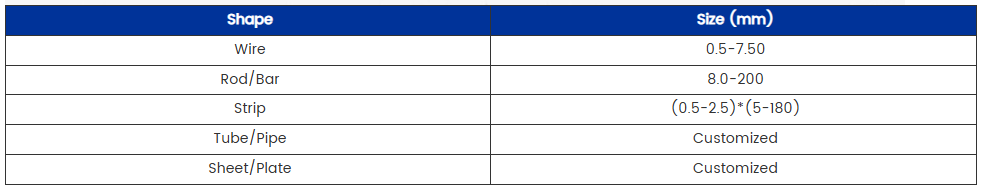

- Specification

- Applications

- FAQs

- Recommended Products

Controlled grain structure with ASTM 8-10 grain size rating

Ultra-low inclusion content (<0.5% non-metallic inclusions)

Homogeneous precipitation of γ' and γ'' strengthening phases

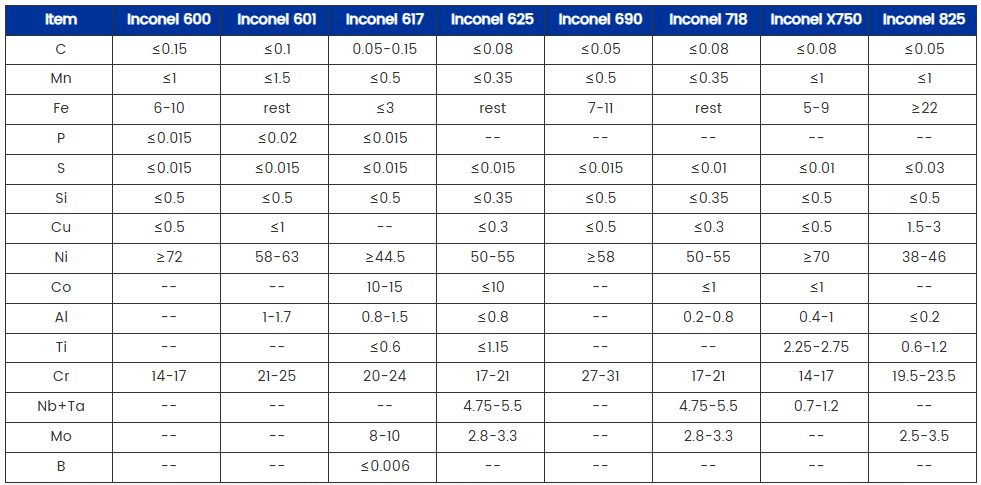

Precise chemistry control (Ni 50-55%, Cr 17-21%, Nb 4.75-5.5%)

Tensile strength: 1,240-1,380 MPa (180-200 ksi)

Fatigue endurance limit: 550 MPa (80 ksi) at 10⁷ cycles

Stress relaxation resistance: <5% load loss after 1,000 hours at 315°C (600°F)

Fracture toughness: 100 MPa√m (91 ksi√in)

Oxidation resistance: <0.5 mg/cm² weight gain after 1,000 hours at 704°C

Corrosion rate: <0.025 mm/year in salt spray (ASTM B117)

Hydrogen embrittlement resistance: No cracking after 200 hours in H₂ environment

Engine Components

Turbine blade retention pins (operating at 650°C/1200°F)

Combustion chamber fasteners (withstanding thermal cycling)

Afterburner ring attachments (exposed to extreme thermal gradients)

Airframe Structures

Primary structural bolts (FST certification required)

Wing attachment fasteners (fatigue-critical applications)

Landing gear pivot pins (high static and dynamic loads)

Flight Control Systems

Actuator torque tubes (precision motion requirements)

Control surface hinges (corrosion-prone environments)

Hydraulic system fittings (high-pressure applications)

Propulsion Systems

Fuel injector springs (1 million+ cycle life requirement)

Variable geometry mechanism springs (thermal expansion compensation)

Bearing preload springs (constant force maintenance)

Landing Gear Assemblies

Oleo strut springs (energy absorption/damping)

Door mechanism return springs (reliable actuation)

Brake stack springs (high-temperature performance)

Avionics Components

Connector contact springs (maintaining electrical continuity)

Relay springs (millions of operational cycles)

Sensor mounting springs (vibration isolation)

Melting and Forming

Triple vacuum arc remelting (VAR) for purity

Controlled hot working for grain refinement

Multi-pass cold drawing with intermediate annealing

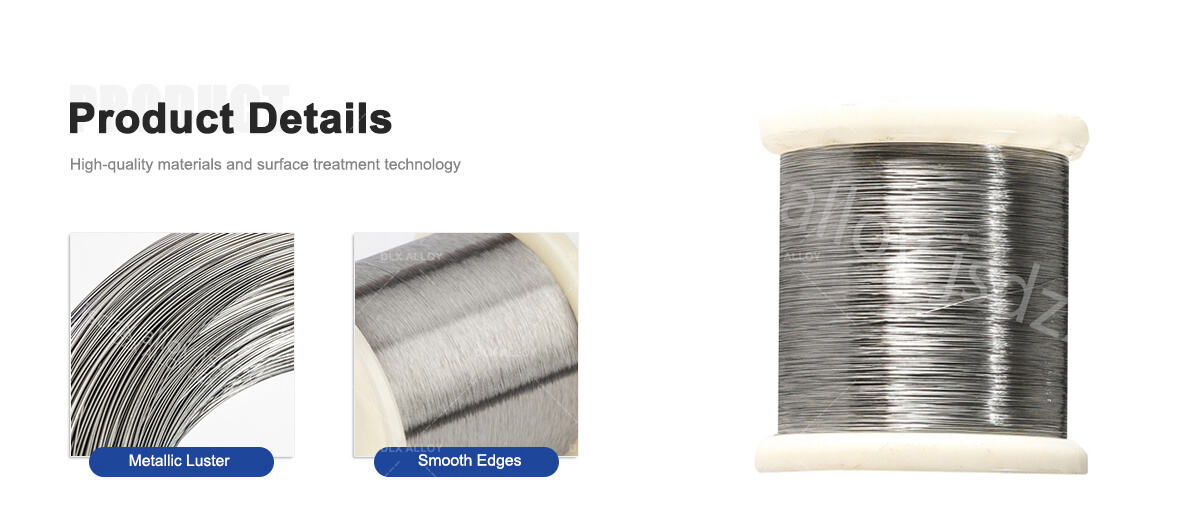

Surface Engineering

Electropolishing to Ra < 0.1 μm

Proprietary passivation treatments

Laser surface modification for select applications

Quality Assurance

100% eddy current testing for defects

Automated dimensional inspection (±0.0025 mm)

Lot traceability through laser marking

Next-gen aircraft programs (Boeing 777X, Airbus A321XLR) increasing demand

Engine OEMs requiring higher temperature materials

MRO market growth driving replacement part needs

Additive Manufacturing Integration

Hybrid manufacturing of complex spring forms

Repair of high-value aerospace components

Customized fastener geometries

Smart Component Development

Embedded strain sensing capability

Shape memory alloy integration

Self-diagnosing fastening systems

Sustainability Initiatives

Closed-loop recycling programs

Reduced energy manufacturing processes

Extended lifecycle engineering

Nanostructured variants for enhanced properties

Improved processability for complex geometries

Cost reduction through optimized chemistry

Metallurgical Characteristics

Precision-engineered Inconel 718 spring wire exhibits exceptional metallurgical properties critical for aerospace applications:

Mechanical Performance

Environmental Resistance

Aerospace Applications

Critical Fastener Systems

Precision Spring Applications

Manufacturing Technology

Precision Production Process

Industry Trends and Future Outlook

Market Drivers

Technological Advancements

Future Material Development

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.