Superelastic Nitinol Wire Shape Memory Alloy for Medical Guidewires & Stents

High-Performance Superelastic Nitinol Wire – Premium Shape Memory Alloy for Medical Guidewires and Self-Expanding Stents

- Overview

- Features

- Applications

- FAQs

- Recommended Products

Our superelastic Nitinol wire represents the gold standard in shape memory alloys for medical device manufacturing. Composed of precisely balanced nickel-titanium (NiTi), this medical-grade Nitinol exhibits unique superelastic properties at body temperature, allowing it to withstand significant deformation (up to 8-10% strain) and return to its original shape without permanent damage.

Key advantages include outstanding biocompatibility, corrosion resistance, and fatigue resistance, making it indispensable for minimally invasive medical devices. Widely trusted in vascular stents, catheter guidewires, and orthodontic applications, this Nitinol SMA wire enables self-expanding designs that compress for easy catheter delivery and expand reliably at the target site. Elevate your endovascular and interventional devices with material that mimics biological flexibility while delivering exceptional mechanical performance.

Key Features of Superelastic Nitinol Shape Memory Alloy Wire

- Superelasticity & Shape Memory Effect— Recovers from high strain deformation, ideal forself-expanding stentsand flexiblemedical guidewiresin tortuous vessels.

- Biocompatibility & Corrosion Resistance— Medical-grade composition minimizes nickel release and ensures long-term safety in implants likevascular stentsandneurovascular devices.

- Kink Resistance & Flexibility— Superior torqueability and pushability for navigating complex anatomy incathetersandendovascular procedures.

- Fatigue Resistance— Withstands repeated stress cycles, enhancing durability in dynamic applications such asperipheral stentsandorthodontic archwires.

- MRI Compatibility— Low magnetic susceptibility for safe use in imaging-guided interventions.

- Precise Dimensions & Surface Finishes— Available in various diameters with oxide or polished surfaces, compliant with ASTM standards for consistent performance.

| Nickel Titanium Wire Chemical Composition | ||||

|

Product Type |

Grade | Fully Annealing Af | Form | Standard |

|

Shape Memory Nitinol Wire |

NiTi-01 | 20℃~40℃ | Wire, Bar, Plate |

Customer specified or Industry Standard (ASTMF2063 Q/XB1516.1 Q/XB1516.2) |

| NiTi-02 | 45℃~90℃ | |||

| Superelastic nitinol alloy | Ni-Ti-SS | -5℃~5℃ | ||

| Low temperature superelastic nitinol alloy | TN3 | -20℃~-30℃ | ||

| TNC | ||||

| Medical nitinol alloy | NiTi-SS |

Active Af 33℃±3℃ |

||

| Narrow hysteresis nitinol alloy | NiTiCu | As-Ms≤5℃ | Wire, Bar | |

| Wide hysteresis nitinol alloy | NiTiNb | As-Ms<150℃ | ||

| NiTiF | ||||

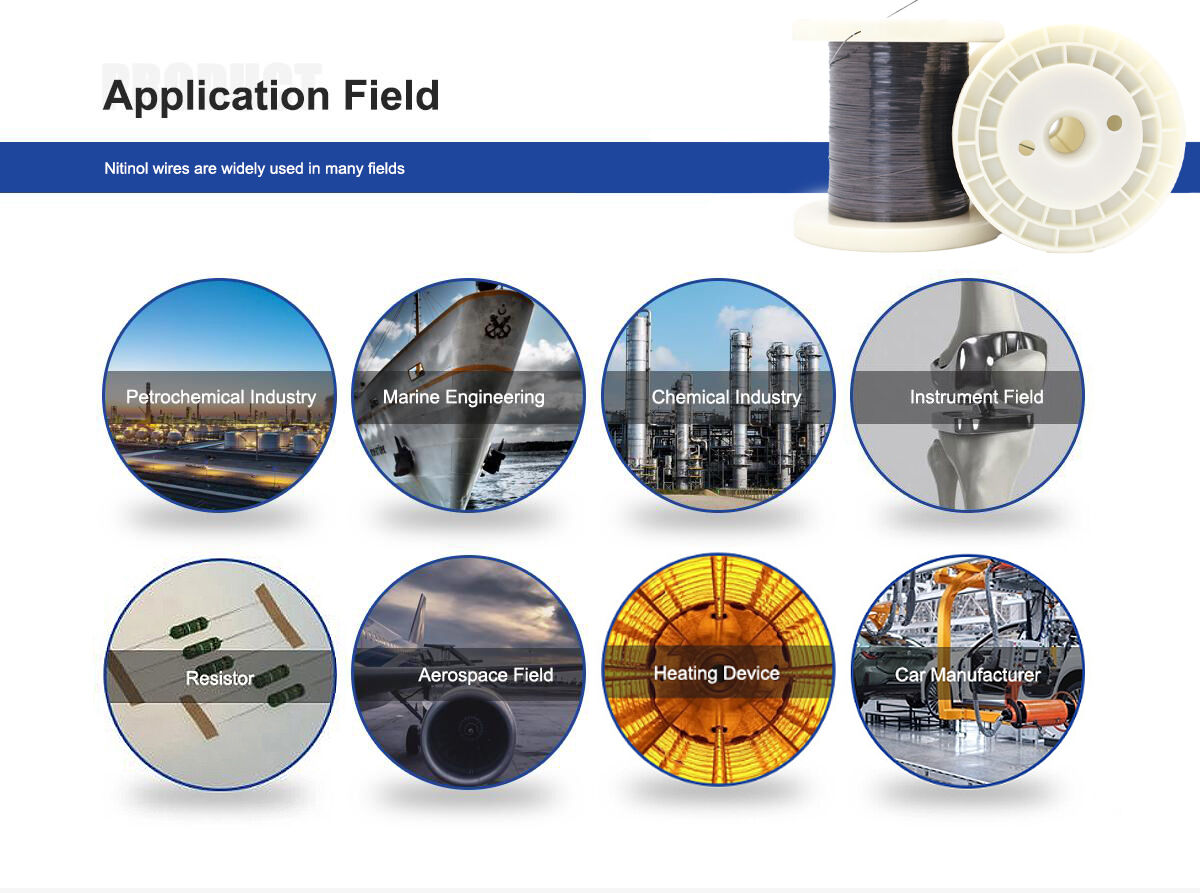

Applications: Medical Uses of Nitinol Wire in Guidewires & Stents

This superelastic Nitinol wire excels in a range of biomedical applications, particularly where precision and reliability are critical:

- Medical Guidewires → Provides exceptional maneuverability and kink resistance for catheter-based interventions in cardiovascular, peripheral, and neurovascular procedures.

- Self-Expanding Stents → Enables compression for minimally invasive delivery and reliable expansion in vascular and peripheral artery disease treatments.

- Orthodontic & Endodontic Devices → Delivers constant gentle force in archwires and files for efficient tooth alignment and root canal shaping.

- Minimally Invasive Surgical Tools → Supports retrieval baskets, embolic filters, and actuators in endovascular and structural heart devices.

- Other Biomedical Implants → Used in heart valve frames, clot retrievers, and filters for enhanced patient outcomes in modern healthcare.

1.What is Nitinol wire and why is it used in medical guidewires and stents?

Nitinol is a nickel-titanium shape memory alloy (NiTi SMA) known for its superelasticity and shape memory effect. In medical guidewires and stents, it allows devices to bend through complex vessels without kinking and recover shape reliably, enabling minimally invasive procedures.

2.Is Nitinol wire biocompatible for long-term implants like stents?

Yes, medical-grade Nitinol is highly biocompatible with excellent corrosion resistance and minimal nickel ion release when properly processed, making it safe for permanent implants such as self-expanding vascular stents.

3.What are the differences between superelastic and shape memory properties in Nitinol?

Superelasticity allows recovery from deformation at constant (body) temperature, ideal for guidewires and stents. The shape memory effect triggers shape recovery upon heating, useful in certain actuators or deployable devices.

4.How does Nitinol compare to stainless steel in medical devices?

Nitinol offers superior flexibility, kink resistance, and fatigue life compared to stainless steel, reducing procedural complications in catheters and endovascular stents while providing better navigation in tortuous anatomy.

5.Can Nitinol wire cause allergic reactions due to nickel?

In medical-grade form with proper surface treatments (e.g., electropolishing), nickel release is negligible, and it is widely used safely in implants. Allergies are rare but should be screened in sensitive patients.

6.What standards does this Nitinol wire meet for medical use?

Our superelastic Nitinol wire complies with ASTM F2063 for chemical composition, mechanical properties, and biocompatibility in medical device applications.