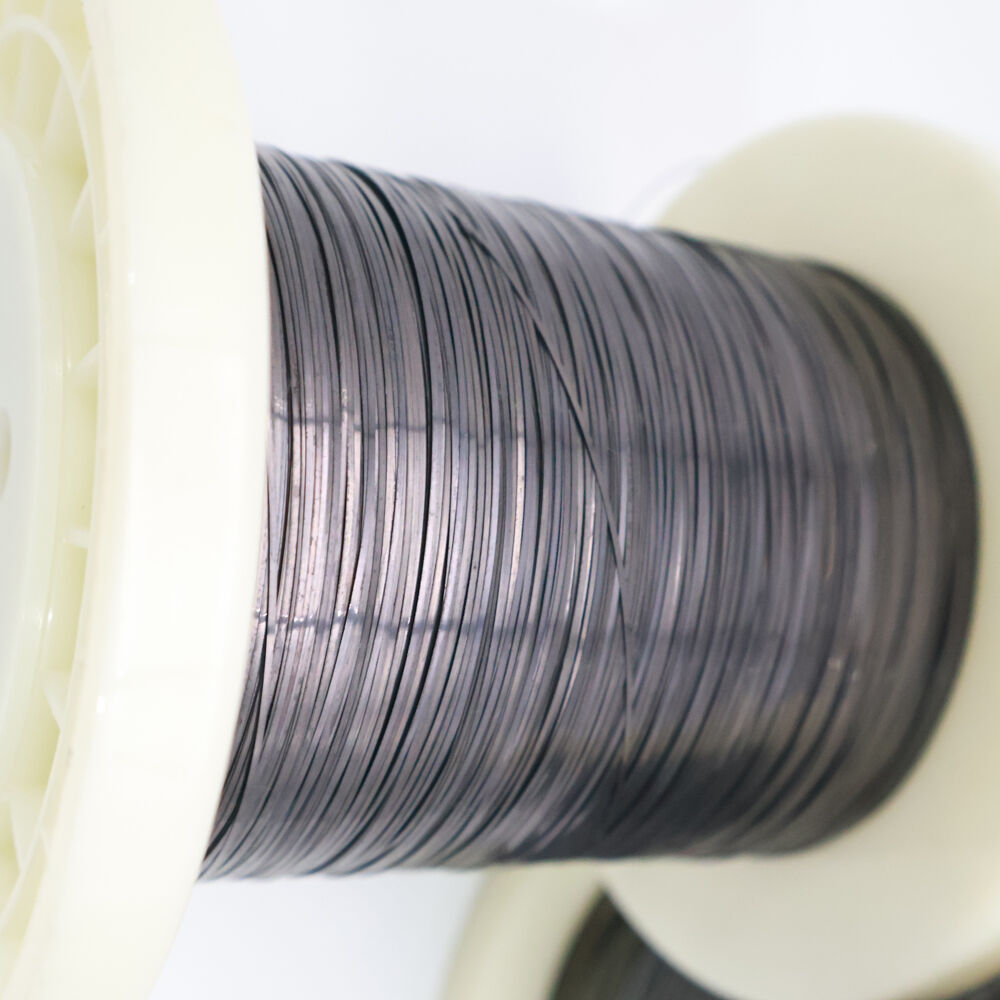

Nitinol Alloy Wire with Shape Memory Effect - Ideal for Surgical Instruments

High-Quality Nitinol Shape Memory Alloy Wire – Superelastic Nickel Titanium (NiTi) for Precision Medical Devices and Minimally Invasive Surgical Instruments

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Product Overview: Nitinol Shape Memory Wire for Surgical and Medical Applications

Our Nitinol alloy wire with shape memory effect is a revolutionary nickel-titanium (NiTi) shape memory alloy designed specifically for advanced surgical instruments and medical device manufacturing. Combining superelasticity with the unique shape memory property, this wire can be deformed at lower temperatures and recover its original shape when heated to body temperature or above, making it indispensable for minimally invasive procedures.

Key highlights include outstanding biocompatibility for safe implantation, superior kink resistance for navigating complex anatomy, and high fatigue resistance for repeated use in dynamic environments. Widely used in endovascular devices, laparoscopic tools, and self-expanding stents, this medical grade Nitinol wire supports precision engineering in cardiology, orthopedics, and urology. Compliant with ASTM F2063, it delivers consistent performance for superelastic Nitinol applications in modern healthcare.

| Nickel Titanium Wire Chemical Composition | ||||

|

Product Type |

Grade | Fully Annealing Af | Form | Standard |

|

Shape Memory Nitinol Wire |

NiTi-01 | 20℃~40℃ | Wire, Bar, Plate |

Customer specified or Industry Standard (ASTMF2063 Q/XB1516.1 Q/XB1516.2) |

| NiTi-02 | 45℃~90℃ | |||

| Superelastic nitinol alloy | Ni-Ti-SS | -5℃~5℃ | ||

| Low temperature superelastic nitinol alloy | TN3 | -20℃~-30℃ | ||

| TNC | ||||

| Medical nitinol alloy | NiTi-SS |

Active Af 33℃±3℃ |

||

| Narrow hysteresis nitinol alloy | NiTiCu | As-Ms≤5℃ | Wire, Bar | |

| Wide hysteresis nitinol alloy | NiTiNb | As-Ms<150℃ | ||

| NiTiF | ||||

Key Features of Superelastic Nitinol Alloy Wire

- Shape Memory Effect — Returns to pre-set shape upon heating, ideal for actuators and deployable surgical tools.

- Superelasticity — Withstands extreme deformation (up to 10x more than stainless steel) without permanent damage, perfect for flexible guidewires and catheters.

- Biocompatibility & Corrosion Resistance — Safe for long-term implantation in the human body, resisting bodily fluids in medical implants.

- High Fatigue Resistance — Endures millions of cycles, ensuring durability in repetitive minimally invasive surgical instruments.

- Kink Resistance — Maintains integrity during navigation through tortuous vessels, enhancing safety in endoscopic devices.

- Temperature-Activated Transformation — Austenite finish temperature (Af) optimized for body temperature activation in self-expanding medical devices.

Applications of Nitinol Shape Memory Alloy Wire in Medical and Surgical Fields

This versatile Nitinol wire excels in a range of biomedical uses:

- Surgical Instruments → Flexible laparoscopic tools, endoscopes, and retrieval baskets for minimally invasive surgery.

- Guidewires & Catheters → Superelastic navigation in vascular and urological procedures.

- Stents & Implants → Self-expanding structures for cardiovascular and orthopedic applications.

- Orthopedic Devices → Bone fixation and spinal implants leveraging shape memory for precise fitting.

1.What is Nitinol alloy wire?

Nitinol is a nickel-titanium (NiTi) shape memory alloy known for its shape memory effect and superelasticity, allowing it to recover its original shape after deformation.

2.How does the shape memory effect work in Nitinol wire?

The wire undergoes a phase transformation from martensite (deformable) to austenite (rigid) when heated above its transition temperature, returning to its programmed shape—ideal for temperature-activated medical devices.

3.Is this Nitinol wire biocompatible for surgical use?

Yes, our medical grade Nitinol meets ASTM F2063 standards, offering excellent biocompatibility and corrosion resistance for safe use in implants and surgical instruments.

4.What are the advantages of superelastic Nitinol over stainless steel?

Superelastic Nitinol provides superior flexibility, kink resistance, and fatigue life, making it better for minimally invasive tools where repeated bending is required.

5.Can Nitinol wire be customized for specific applications?

Yes, we offer various diameters, surface finishes (oxide or polished), and transition temperatures tailored for surgical or endovascular needs.

6.What is the typical activation temperature for medical Nitinol wire?

For body temperature applications, the austenite finish (Af) is around 37°C, enabling activation inside the body for self-expanding devices.