NiCr Alloy Wire 80/20 - Oxidation Proof Heating Element

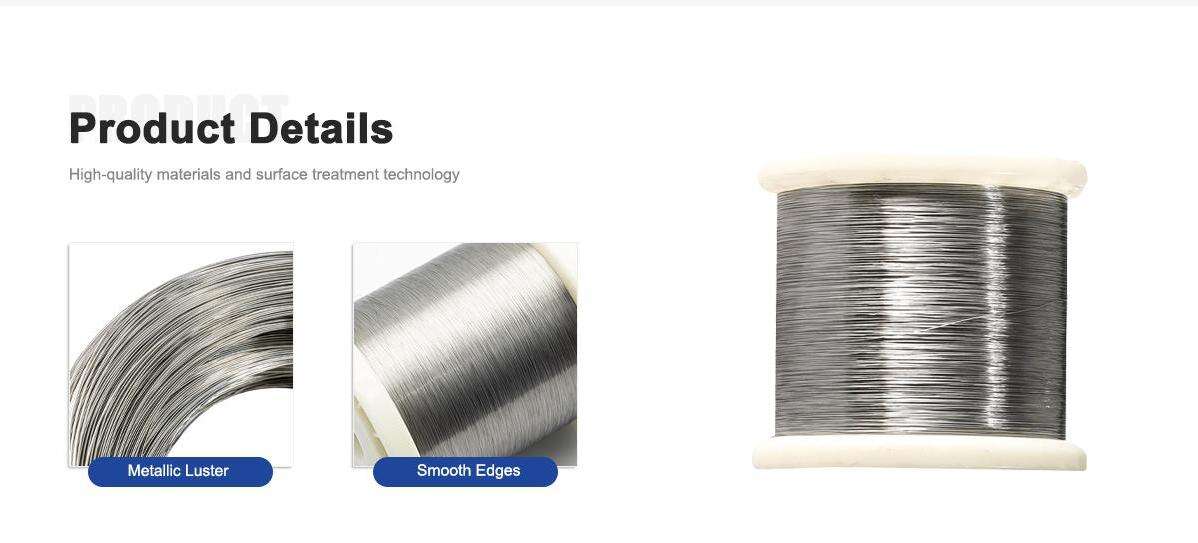

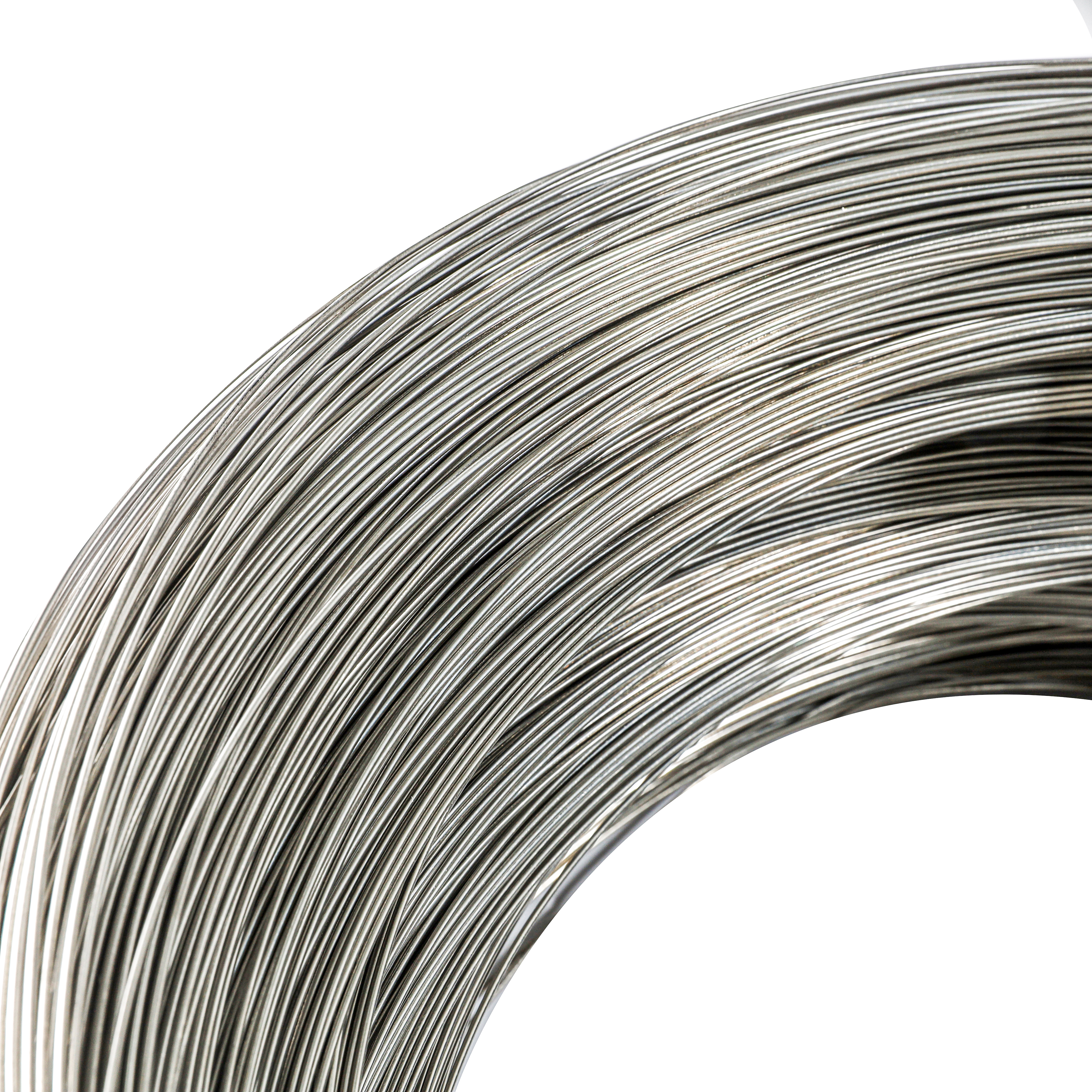

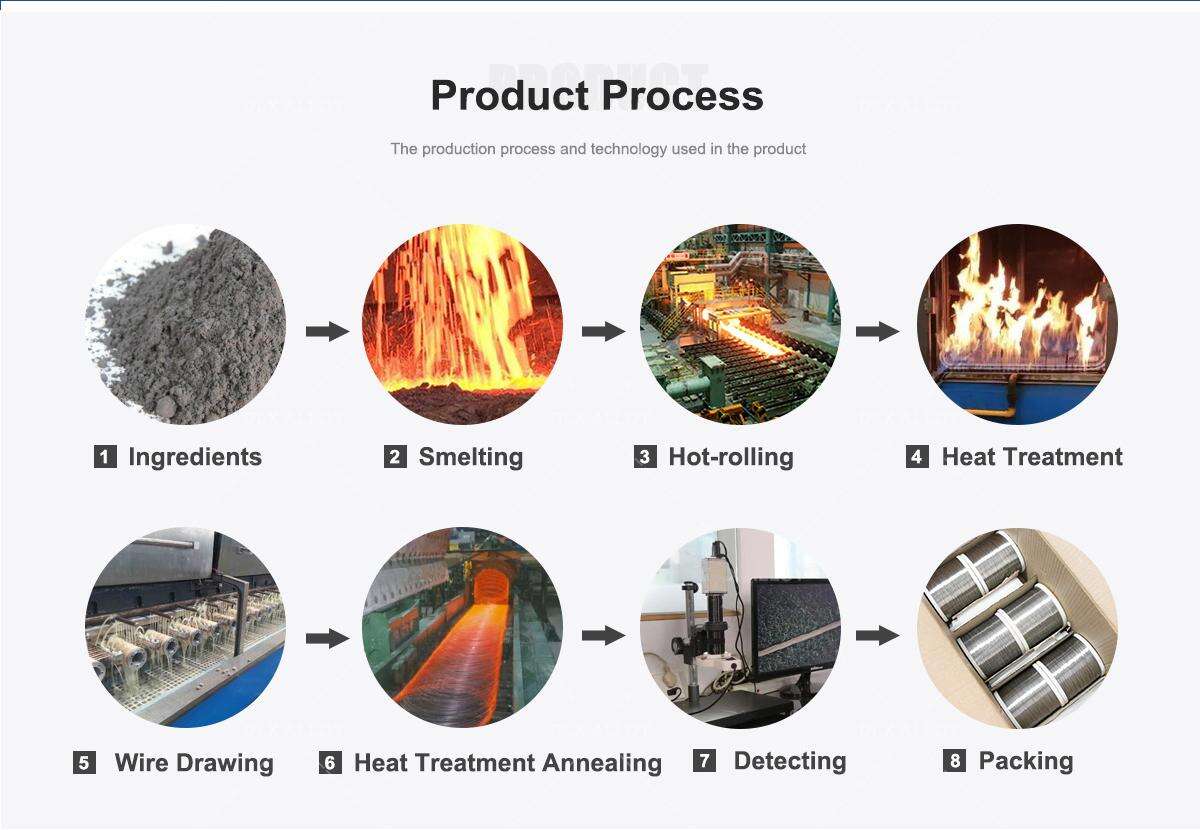

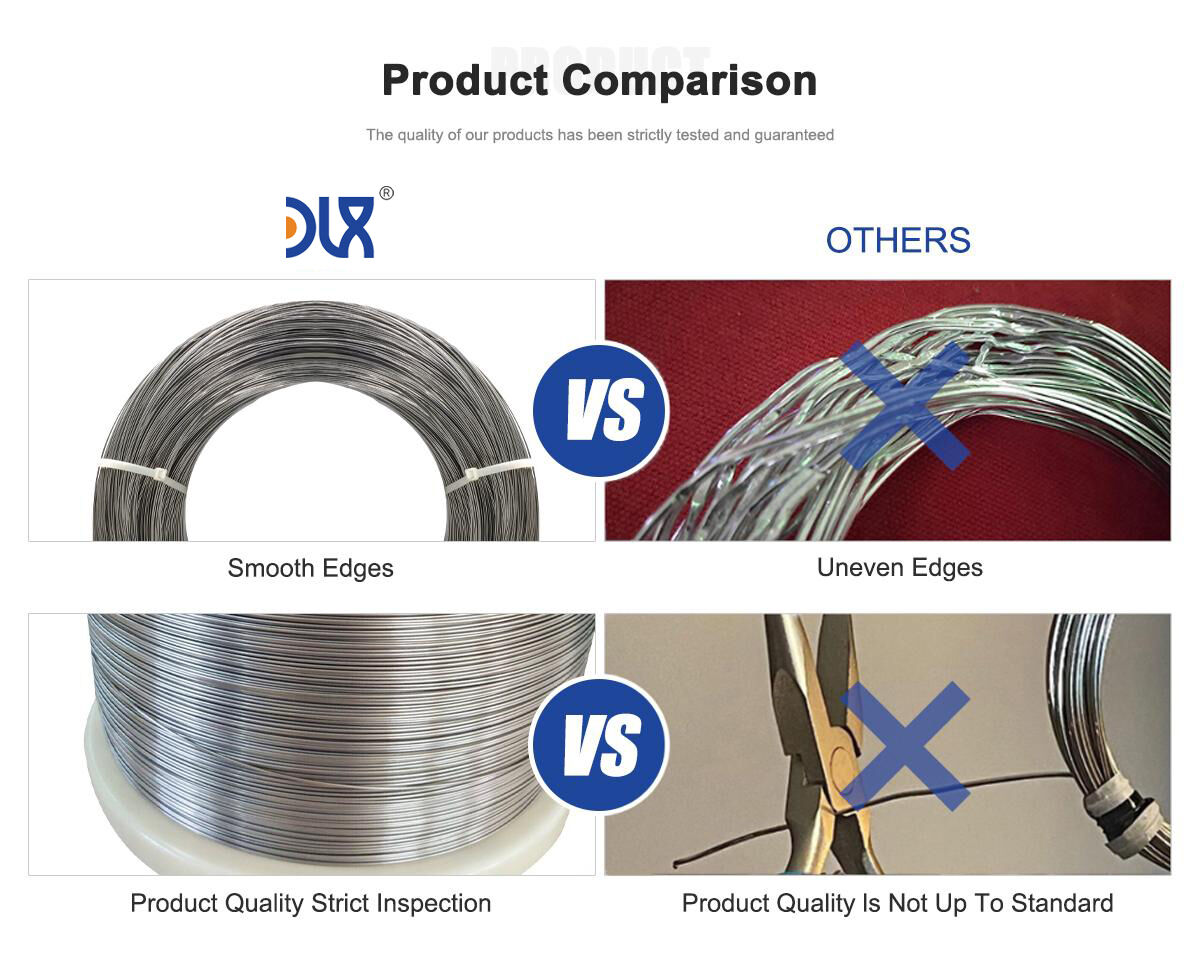

Discover the superior quality of our NiCr Alloy Wire 80/20, engineered as an oxidation proof heating element for demanding environments. This nichrome resistance wire, composed of 80% nickel and 20% chromium, offers exceptional thermal stability and corrosion resistance, making it ideal for high-temperature applications. Whether you're sourcing nichrome heating wire for furnaces, toasters, or industrial heaters, this alloy ensures longevity and efficiency. Our NiCr 80/20 wire stands out in the market for its ability to withstand oxidation at elevated temperatures, providing a cost-effective alternative to other resistance heating alloys like Kanthal or Inconel wires.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- High Oxidation Resistance in Nichrome Heating Elements: Engineered to resist scaling and degradation at temperatures up to 1200°C, ensuring prolonged service life for your resistance wire applications.

- Superior Electrical Resistivity for Efficient Heating Wire Performance: With a resistivity of approximately 1.09 μΩ·m, this NiCr alloy wire delivers precise heat output, perfect for custom nichrome coils and industrial heating systems.

- Excellent Mechanical Strength in Oxidation Resistant Alloy Wires: Maintains tensile strength even after repeated thermal cycling, making it suitable for robust heating element designs like those in kilns or ovens.

- Corrosion and Heat Resistance in Cr20Ni80 Nichrome Wire: Outperforms in humid or corrosive environments, offering a reliable alternative to FeCrAl wires for long-term use.

Overview of NiCr 80/20 Alloy Wire:

In the realm of resistance heating materials, NiCr Alloy Wire 80/20 emerges as a top choice for oxidation proof applications. This nichrome wire variant, often referred to as Nichrome 80 or Cr20Ni80, is designed for electric heating elements that require consistent performance under extreme heat. With a melting point around 1400°C and excellent resistivity, it excels in converting electrical energy into heat efficiently. Ideal for global industries seeking reliable heating wire solutions, this alloy combines affordability with robustness, outperforming standard iron-chrome-aluminum wires in oxidative atmospheres. From manufacturing to laboratory use, NiCr 80/20 provides a versatile foundation for custom heating coils and elements.

Key Features of NiCr 80/20 Resistance Wire:

| Performance material | Cr10Ni90 | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

|---|---|---|---|---|---|---|---|

| composition | Ni | 90 | Rest | Rest | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | -- | ≤1.0 | ≤1.0 | Rest | Rest | Rest | |

| Maximum temperature℃ | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Meltiing point ℃ | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Density(g/cm3) | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Resistivity | -- | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | |

| Elongation at rupture | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heat J/g.℃ | -- | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

| Thermal conductivity KJ/m.h℃ | -- | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient of lines expansion | -- | 18 | 17 | 17 | 19 | 19 | |

| Micrographic structure | -- | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | -- | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic | Nonmagnetic |

Applications of NiCr Alloy Wire 80/20 :

- Industrial Furnaces and Kilns with Nichrome Heating Elements: Essential for high-temperature processes in metallurgy and ceramics, where oxidation resistant wire ensures consistent heating.

- Household Appliances Featuring Resistance Heating Wires: Commonly used in toasters, hair dryers, and space heaters for safe, efficient nichrome coil operation.

- Laboratory Equipment Utilizing Cr20Ni80 Alloy Wires: Ideal for scientific instruments requiring precise temperature control in oxidation proof environments.

- Automotive and Aerospace Nichrome Wire Solutions: Applied in sensors and de-icing systems, leveraging the alloy's durability against thermal stress.

- Custom Manufacturing of Heating Elements with NiCr 80/20: Perfect for 3D printing resistors, vaping coils, or foam cutting tools, adapting to diverse global industry needs.

FAQ for NiCr 80/20 Alloy Wire:

1.What is the maximum operating temperature for NiCr Alloy Wire 80/20 as an oxidation proof heating element?

The NiCr 80/20 resistance wire can operate continuously up to 1200°C in oxidative atmospheres, making it a preferred nichrome heating material for high-heat applications.

2.How does NiCr 80/20 compare to other nichrome wires or resistance heating alloys?

Compared to NiCr 60/15 or FeCrAl wires, the 80/20 variant offers better oxidation resistance and higher resistivity, ideal for demanding nichrome coil designs while being more cost-effective than premium alloys like Inconel.

3.Can this oxidation resistant nichrome wire be used in custom heating element projects?

Yes, our NiCr Alloy Wire 80/20 is highly customizable for resistance heating wire projects, with options for annealing and coiling to fit specific industrial or DIY needs.

4.What gauge sizes are available for Cr20Ni80 nichrome heating wire?

We offer a range from fine 0.05mm for precision applications to thicker 5mm+ for heavy-duty heating elements, ensuring versatility in oxidation proof wire selections.

5.Is NiCr 80/20 alloy wire suitable for global shipping and international use in resistance heating systems?

Absolutely, this nichrome resistance wire complies with international standards like ASTM and is available for worldwide delivery, supporting SEO-optimized sourcing for industries in the US, Europe, Asia, and beyond.