Nickel Titanium Nitinol Wire 1.0mm Shape Memory Effect for Actuators & Sensors

High-Quality 1.0mm Nitinol Wire with Shape Memory Effect – Nickel Titanium Alloy for Precision Actuators and Sensors.

- Overview

- Features & Applications

- FAQs

- Recommended Products

- Diameter: 1.0mm for robust strength and actuation force

- Activation via heat (electrical current or environmental)

- Excellent cycle life and durability for repeated use

- Ideal for shape memory actuators, thermal sensors, and responsive mechanisms

Discover premium Nickel Titanium Nitinol Wire in 1.0mm diameter, engineered for exceptional shape memory effect and superelasticity. This NiTi alloy wire, also known as shape memory alloy (SMA), returns to its predefined shape when heated, making it ideal for advanced applications in actuators, sensors, robotics, and industrial systems. With superior biocompatibility, corrosion resistance, and high fatigue life, our Nitinol shape memory wire delivers reliable performance in demanding environments. Perfect for prototypes, research, or production – experience the power of smart materials with this versatile NiTi wire.

Product Overview: Nitinol Shape Memory Alloy Wire for Actuators and Sensors

Our 1.0mm Nitinol wire is a high-performance nickel titanium alloy featuring the renowned shape memory effect (SME) and superelastic properties. When deformed at lower temperatures (martensite phase), this SMA wire effortlessly recovers its original austenite shape upon heating above its transition temperature. This NiTi shape memory wire excels in precision actuation, offering significant force generation in compact designs.

Key highlights include:

Whether you're developing robotic systems, medical devices, or aerospace components, this Nitinol SMA wire provides unmatched reliability and innovation in smart material technology.

Key Features of 1.0mm Nitinol Wire with Shape Memory Effect

- Shape Memory Effect: Returns to pre-trained shape when heated, enabling powerful linear or contractile actuation in NiTi actuators

- Superelasticity: Withstands large deformations without permanent damage, perfect for flexible sensors and vibration damping

- High Fatigue Resistance: Supports millions of cycles, ensuring longevity in dynamic shape memory alloy applications

- Biocompatibility & Corrosion Resistance: Safe for sensitive environments, including potential medical or industrial uses

- Precise Phase Transformation: Controlled austenite-martensite transition for reliable performance in Nitinol muscle wire setups

- Customizable Activation: Trainable for specific shapes and temperatures, versatile for actuators and sensors

| Nickel Titanium Wire Chemical Composition | ||||

|

Product Type |

Grade | Fully Annealing Af | Form | Standard |

|

Shape Memory Nitinol Wire |

NiTi-01 | 20℃~40℃ | Wire, Bar, Plate |

Customer specified or Industry Standard (ASTMF2063 Q/XB1516.1 Q/XB1516.2) |

| NiTi-02 | 45℃~90℃ | |||

| Superelastic nitinol alloy | Ni-Ti-SS | -5℃~5℃ | ||

| Low temperature superelastic nitinol alloy | TN3 | -20℃~-30℃ | ||

| TNC | ||||

| Medical nitinol alloy | NiTi-SS |

Active Af 33℃±3℃ |

||

| Narrow hysteresis nitinol alloy | NiTiCu | As-Ms≤5℃ | Wire, Bar | |

| Wide hysteresis nitinol alloy | NiTiNb | As-Ms<150℃ | ||

| NiTiF | ||||

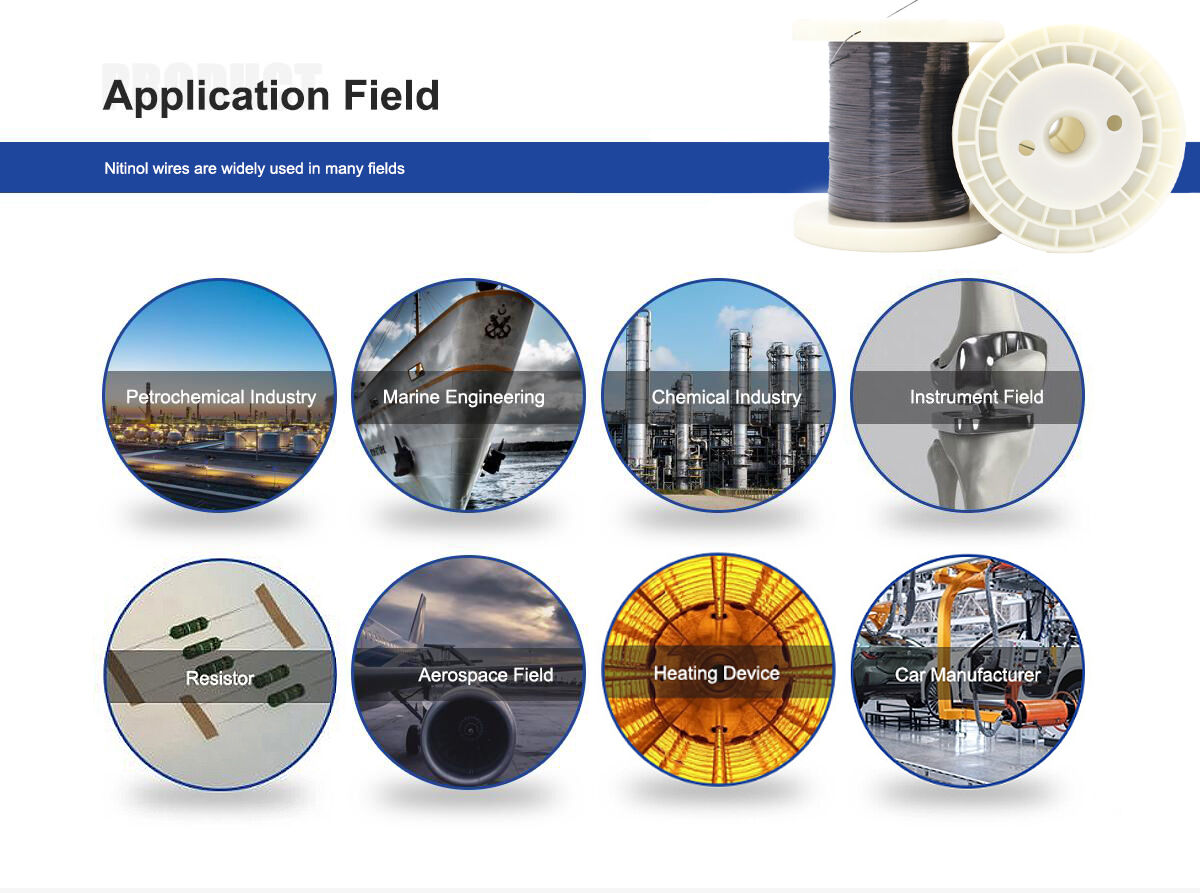

Applications of Nickel Titanium Nitinol Wire in Actuators & Sensors

This 1.0mm Nitinol shape memory wire is widely used across industries leveraging its unique SMA properties:

- Robotic Actuators: Functions as "muscle wire" for compact, silent movement in robotics and automation

- Thermal Sensors & Switches: Detects temperature changes for self-actuating mechanisms

- Aerospace & Automotive: Deployable structures, vibration control, and precise positioning

- Industrial Valves & Latches: Heat-activated release or locking systems

- Research & Prototyping: Ideal for experimenting with shape memory effect in innovative designs

- Miniature Devices: High force-to-weight ratio for drones, MEMS, and micro-actuators

1.What is the shape memory effect in Nitinol wire?

The shape memory effect allows the NiTi alloy to be deformed in its martensite phase and recover its original austenite shape when heated above the transition temperature, generating significant force ideal for actuators.

2.How do I activate the Nitinol wire?

Activation occurs by heating via electrical current (Joule heating), hot water, or ambient temperature rise. For 1.0mm shape memory wire, response time depends on current and cooling method.

3.Can I retrain the shape of this Nitinol SMA wire?

Yes! Heat the wire to approximately 500°C while constrained in the desired shape, hold for 10-45 minutes (depending on diameter), then quench in water to set the new shape memory.

4.What is the typical transition temperature for this wire?

Transition temperatures vary; common ranges are 40-90°C for actuation. Specify your needs for customized Af temperature in Nitinol actuators.

5.Is this Nitinol wire superelastic?

Primarily focused on shape memory effect, it also exhibits superelasticity at higher temperatures, allowing recovery from strains up to 10% without deformation.

6.How durable is 1.0mm Nitinol wire in repeated cycles?

With proper design (avoiding overstress), it supports high cycle life (up to millions), thanks to excellent fatigue resistance in shape memory alloys.

7.What safety precautions should I take?

Nitinol is biocompatible and non-toxic, but avoid overheating above 150°C to prevent damage. Use appropriate current limits for electrical activation in sensors and actuators.