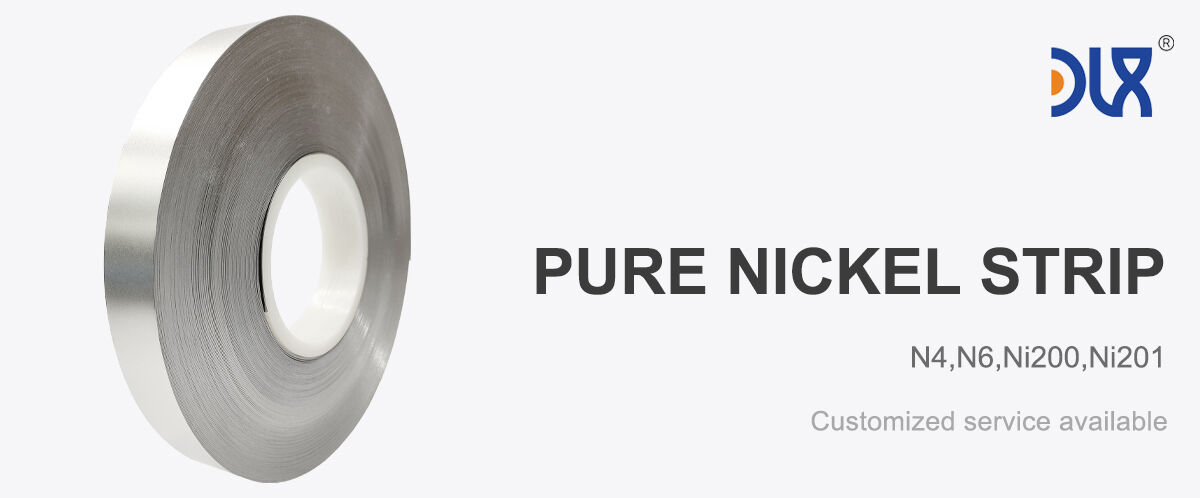

N6 Grade Pure Nickel Foil with Excellent Ductility for Industrial Use

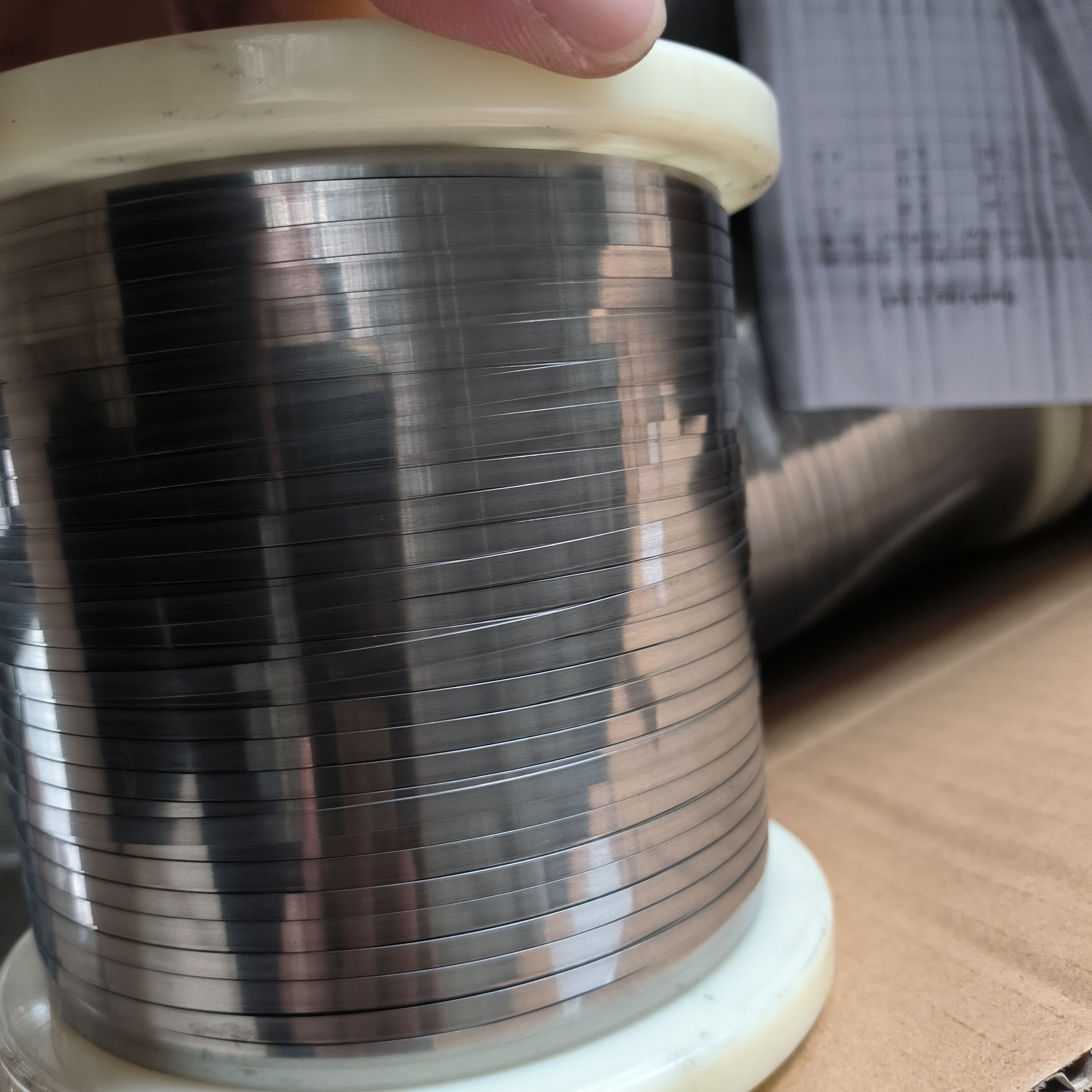

Our N6 grade pure nickel foil is a high-purity nickel material (99.6% minimum purity) designed specifically for demanding industrial environments. This ductile nickel sheet offers exceptional malleability, allowing it to be easily formed, bent, or stamped without cracking, making it ideal for precision engineering and fabrication processes.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- High Purity and Ductility in Nickel Foil Materials: Boasting 99.6% pure nickel composition, this foil exhibits outstanding ductility, enabling seamless forming and welding in industrial nickel applications without brittleness.

- Corrosion and Oxidation Resistance for Durable Nickel Strips: Engineered to withstand aggressive environments, our N6 grade nickel sheet offers superior resistance to acids, alkalis, and high temperatures, ideal for chemical industry nickel foil uses.

- Excellent Thermal and Electrical Conductivity in Pure Nickel Products: With top-tier conductivity properties, this ductile nickel foil supports efficient heat transfer and electrical performance, perfect for battery nickel strips and electronic components.

- Compliance with Standards in High-Purity Nickel Foil: Adhering to ASTM B162 and ISO certifications, this industrial-grade nickel strip ensures consistent quality and reliability for global supply chains.

Introduction to High-Ductility Pure Nickel Foil N6 Grade

N6 grade pure nickel foil stands out as a versatile and reliable choice for industrial use. This high-purity nickel sheet, known for its excellent ductility, is produced through meticulous refining processes to achieve a minimum 99.6% nickel content, free from impurities that could compromise performance. Its superior flexibility and strength make it a preferred ductile nickel material in sectors requiring precision and resilience, such as renewable energy storage and automotive parts. As a leading supplier of industrial nickel foil, we ensure our products meet stringent quality controls, offering customizable options to suit specific project needs. This overview highlights how our corrosion-resistant nickel strip enhances efficiency in manufacturing, providing a cost-effective solution for engineers and fabricators worldwide seeking high-performance pure nickel products.

Key Characteristics of Pure N6 Nickel Strip

| Specification | Details |

|---|---|

| Material | N4 N201 Pure Nickel (≥99.9%) |

| Thickness | 0.1mm – 0.3mm (Customizable) |

| Width | Up to 300mm (Customizable) |

| Standard Compliance | ASTM B162, GB/T 2054-2005 |

| Melting Point | 1453°C (2647°F) |

| Tensile Strength | ≥380 MPa |

| Electrical Resistivity | ≤0.099 Ω·mm²/m |

Uses of Corrosion Resistant 99.6% Pure Nickel Strip in Electronics

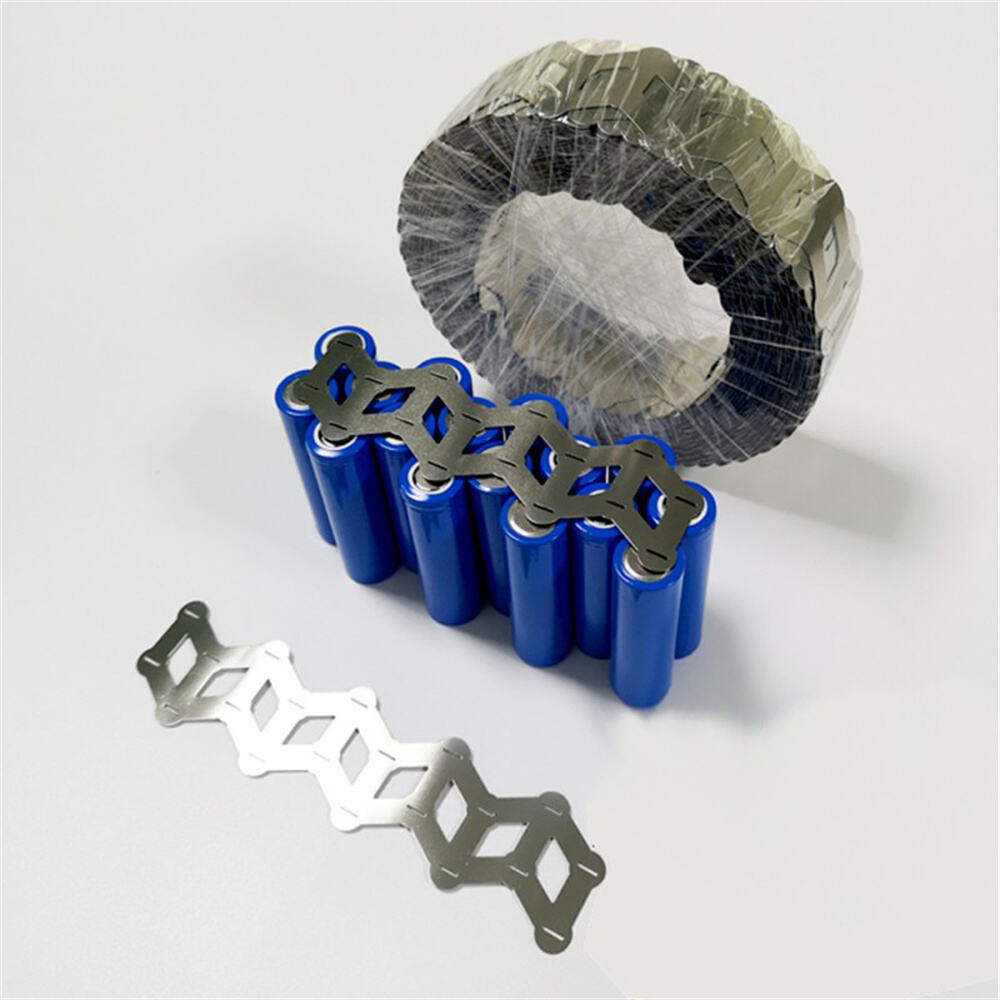

- Battery Manufacturing with Ni200 Nickel Tape: Essential for lithium-ion battery tabs and connectors, providing corrosion resistance and reliable conductivity in energy storage solutions worldwide.

- Electronic Components Using Pure Nickel Foil: Ideal for shielding, grounding, and circuit elements in devices like smartphones, laptops, and automotive electronics, enhancing durability in humid or corrosive settings.

- Industrial Sensors and Instrumentation Nickel Strip: Applied in sensors exposed to chemical environments, ensuring stable performance in manufacturing plants across Europe and North America.

- Aerospace and Marine Electronics with Corrosion Resistant Tape: Used in high-reliability systems where resistance to saltwater and extreme conditions is critical, supporting global aerospace and marine industries.

- Renewable Energy Applications for N6 Nickel Foil: Integrated into solar panels and wind turbine components for efficient electrical connections in eco-friendly energy systems.

FAQs of Ni201 Nickel Tape :

1.What is the purity level of this ductile N6 grade nickel foil for industrial use?

Our N6 pure nickel strip maintains a minimum purity of 99.6%, making it a high-quality nickel material suitable for corrosion-resistant applications in manufacturing and electronics.

2.How does the excellent ductility benefit industrial nickel sheet applications?

The superior ductility of this pure nickel foil allows for easy bending, stamping, and forming without fractures, ideal for complex fabrications in battery production and aerospace nickel products.

3.Is this high-purity N6 nickel foil compliant with international standards for global industrial solutions?

Yes, it adheres to ASTM B162 and other relevant standards, ensuring reliability for worldwide users seeking ductile nickel strips for chemical and electrical industries.

4.Can this N6 grade nickel sheet be used in high-temperature environments for industrial fabrication?

Absolutely, with excellent thermal stability up to 600°C, it's perfect for heat exchangers and other high-performance pure nickel applications in demanding industrial conditions.