Monel 400 Nickel Alloy Spray Wire - Marine Corrosion Protection and Durability

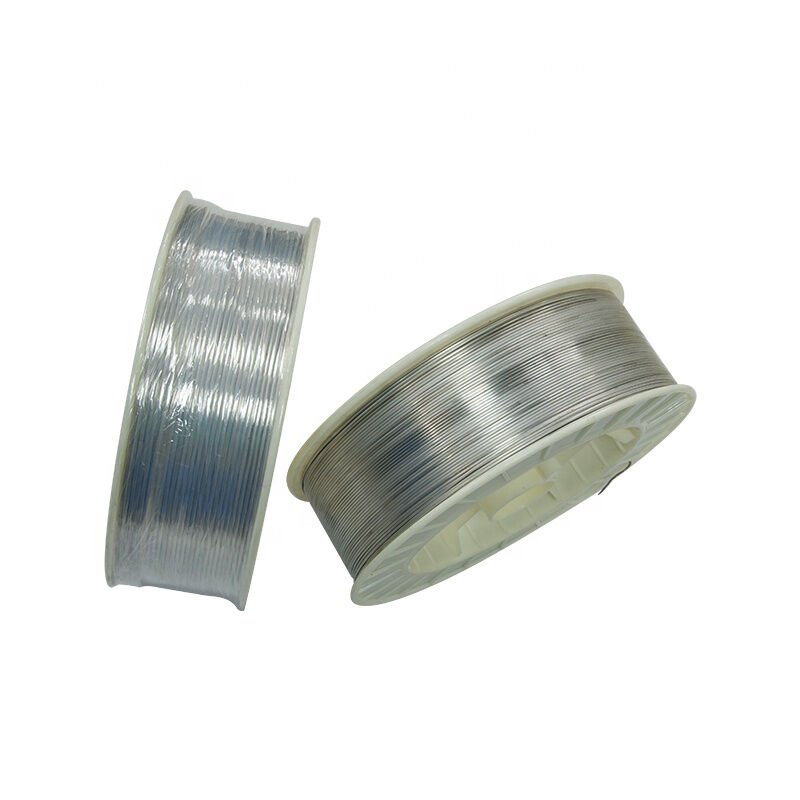

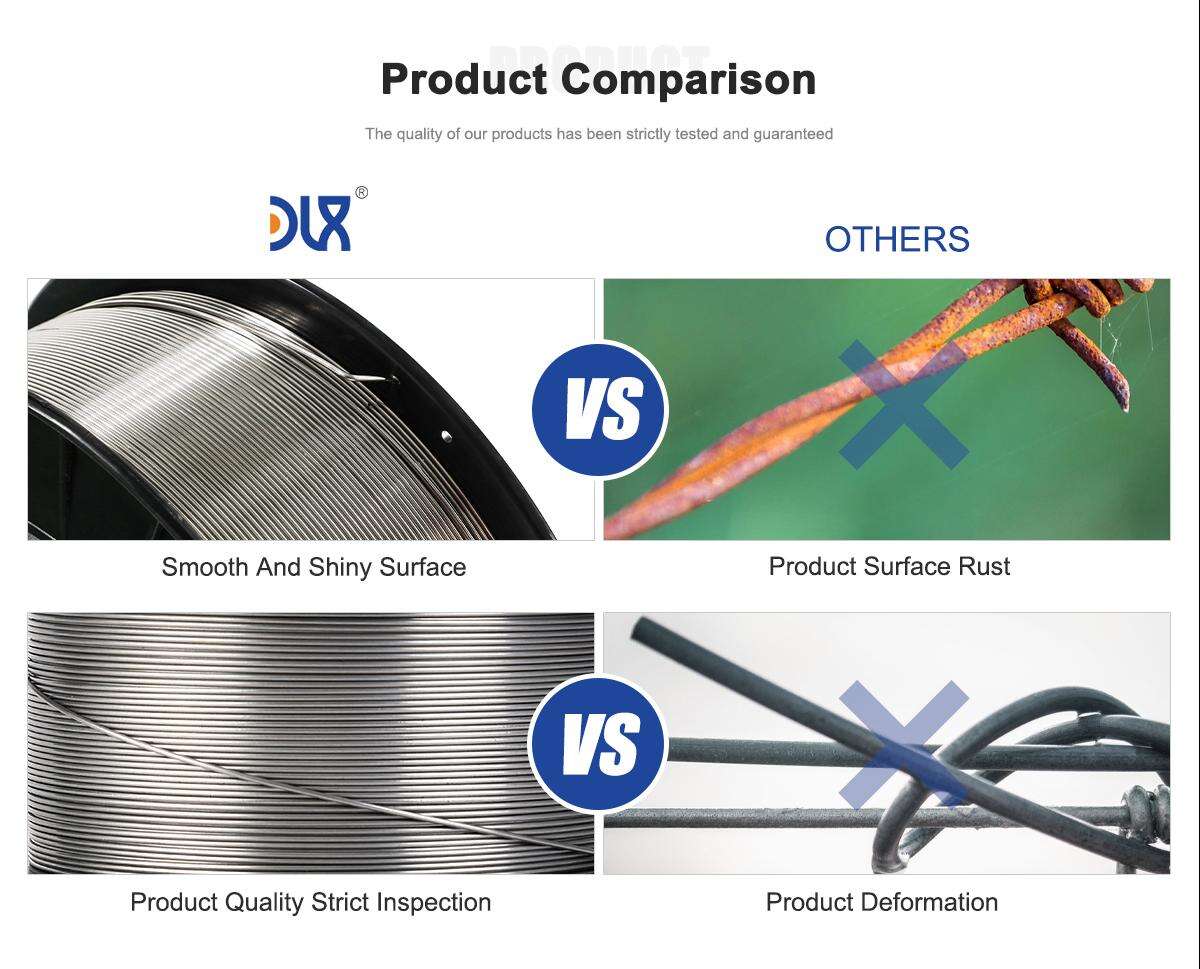

Discover the ultimate solution in thermal spray coatings with our Monel 400 nickel alloy spray wire. This high-quality nickel copper alloy wire is specifically designed for exceptional corrosion resistance in marine and saltwater environments, providing unmatched durability against pitting, crevice corrosion, and stress corrosion cracking.

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Overview of Monel 400 Nickel Alloy Spray Wire:

Monel 400 is a versatile nickel-copper alloy renowned for its outstanding resistance to corrosion in marine and chemical environments. As a thermal spray wire, it is used in arc spraying processes to apply protective coatings that enhance the durability of metal surfaces exposed to harsh conditions. This alloy wire combines high tensile strength with excellent ductility, making it suitable for a wide range of applications from seawater desalination plants to oil and gas platforms. Key benefits include superior resistance to hydrofluoric acid, sulfuric acid, and alkaline solutions, ensuring long-term performance in corrosive atmospheres. Whether for repair or preventive maintenance, Monel 400 spray wire delivers cost-effective, high-performance corrosion protection that meets industry standards like ASTM B127 and UNS N04400 specifications.

Key Features of Monel 400 Nickel Alloy Spray Wire:

- Exceptional Corrosion Resistance in Saltwater and Marine Settings: This nickel copper alloy wire excels in resisting corrosion from seawater, brine, and marine atmospheres, preventing pitting and crevice damage in offshore and coastal applications.

- High Mechanical Strength and Ductility for Thermal Spray Applications: With a tensile strength up to 80 ksi, Monel 400 thermal spray wire maintains integrity under high-stress conditions, ideal for arc spraying on structural components.

- Resistance to Acids, Alkalis, and Chemical Environments: Offers robust protection against hydrofluoric, sulfuric, and phosphoric acids, making it a top choice for chemical processing and industrial alloy wire solutions.

- Excellent Weldability and Bonding in Spray Coating Processes: Ensures strong adhesion in thermal arc spraying, providing uniform coatings that enhance surface durability without cracking or peeling.

- Temperature Stability for High-Heat Industrial Uses: Performs reliably up to 1000°F (538°C), suitable for high-temperature environments in power generation and aerospace alloy applications.

- Compliance with Industry Standards like UNS N04400 and ASTM Specifications: Meets global quality benchmarks for nickel alloy materials, ensuring reliability in marine engineering and corrosion-resistant wire projects.

Applications of Monel 400 Nickel Alloy Spray Wire:

- Marine and Shipbuilding Industry: Applied for coating propellers, hulls, and pumps to combat seawater corrosion, extending service life in naval and commercial shipping.

- Offshore Oil and Gas Platforms: Used in thermal spraying for pipelines, valves, and rigs to provide corrosion resistance against harsh subsea environments and saltwater exposure.

- Chemical Processing Equipment: Ideal for protecting tanks, heat exchangers, and piping from acidic and alkaline corrosion in refineries and petrochemical plants.

- Desalination and Water Treatment Facilities: Enhances durability of components exposed to brine and high-salinity water, preventing erosion and pitting in coastal water systems.

- Power Generation and Aerospace Components: Offers reliable alloy wire coatings for turbines and exhaust systems requiring high-temperature corrosion protection.

- General Industrial Maintenance and Repair: Employed in arc spray applications for restoring worn parts in manufacturing, mining, and construction sectors demanding long-lasting nickel alloy solutions.

1.What makes Monel 400 nickel alloy spray wire ideal for marine corrosion protection?

Monel 400's unique nickel-copper composition provides superior resistance to saltwater, pitting, and crevice corrosion, making it a preferred choice for offshore and coastal thermal spray applications.

2.How does this thermal spray wire compare to other nickel alloys in terms of durability?

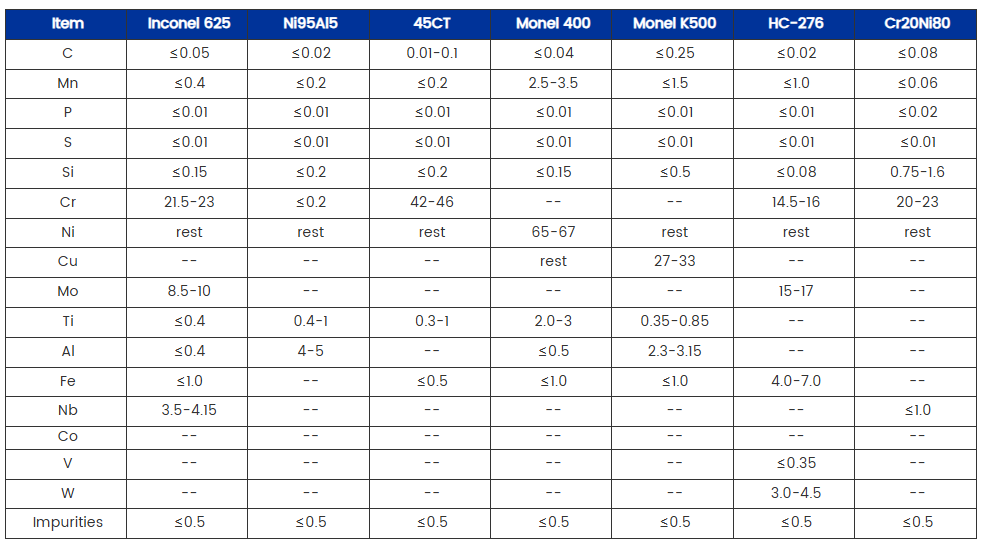

Compared to alloys like Inconel or Hastelloy, Monel 400 offers excellent cost-effectiveness with high ductility and corrosion resistance, especially in non-oxidizing environments like marine settings.

3.Can Monel 400 alloy wire be used in high-temperature industrial applications?

Yes, it maintains structural integrity up to 1000°F, suitable for thermal arc spraying in power plants and chemical industries requiring durable corrosion-resistant coatings.

4.Is this spray wire suitable for DIY or professional thermal spraying?

While professionals in shipbuilding and offshore industries commonly use it, proper equipment like arc spray guns is required for optimal application and corrosion protection results.