Medical Grade Shape Memory Nitinol Tube - Precision Hypotube

Superelastic NiTi Alloy Hypotube for Minimally Invasive Medical Devices – High-Precision Shape Memory Nitinol Tubing

- Overview

- Specification

- Features & Applications

- Product FAQs

- Recommended Products

Product Overview:Superelastic Nitinol Hypotube for Medical Device Innovation

Our medical grade shape memory nitinol tube represents cutting-edge NiTi alloy technology tailored for precision hypotube applications in the medical field. Known as a superelastic nitinol hypotube, this tubing harnesses the unique properties of nickel-titanium alloy – including shape memory and pseudoelasticity – to enable groundbreaking minimally invasive devices.

Designed for biocompatibility and durability, this precision nitinol tubing excels in navigating complex anatomical pathways without permanent deformation. Whether used in cardiovascular, neurovascular, or peripheral interventions, our NiTi hypotube provides superior flexibility, kink resistance, and fatigue endurance compared to traditional stainless steel alternatives. Compliant with medical standards, it supports laser cutting, shape setting, and custom fabrication for stents, guidewires, catheters, and endoscopic instruments.

Experience the advantages of advanced shape memory alloy tubing that enhances device trackability, pushability, and overall patient outcomes in modern interventional medicine.

| Nickel Titanium Wire Chemical Composition | ||||

|

Product Type |

Grade | Fully Annealing Af | Form | Standard |

|

Shape Memory Nitinol Wire |

NiTi-01 | 20℃~40℃ | Wire, Bar, Plate |

Customer specified or Industry Standard (ASTMF2063 Q/XB1516.1 Q/XB1516.2) |

| NiTi-02 | 45℃~90℃ | |||

| Superelastic nitinol alloy | Ni-Ti-SS | -5℃~5℃ | ||

| Low temperature superelastic nitinol alloy | TN3 | -20℃~-30℃ | ||

| TNC | ||||

| Medical nitinol alloy | NiTi-SS |

Active Af 33℃±3℃ |

||

| Narrow hysteresis nitinol alloy | NiTiCu | As-Ms≤5℃ | Wire, Bar | |

| Wide hysteresis nitinol alloy | NiTiNb | As-Ms<150℃ | ||

| NiTiF | ||||

Key Features of Our Precision Shape Memory Nitinol Hypotube

- Superelasticity and Shape Memory Effect: Recovers from up to 8-10% strain without permanent deformation, ideal for flexible medical hypotubes in dynamic environments.

- Biocompatibility and Corrosion Resistance: Medical-grade NiTi alloy safe for long-term implantation, resistant to bodily fluids for stents and implants.

- Kink Resistance and Fatigue Strength: Maintains integrity under cyclic loading, perfect for guidewires and catheter shafts in tortuous vessels.

- Precision Tolerances and Thin-Wall Design: Tight OD/ID control with ultra-thin walls for micro-scale hypotubes in minimally invasive devices.

- Excellent Torque Transmission and Pushability: Enhances trackability in neurovascular and cardiovascular applications.

- Customizable Af Temperature: Tailored transformation temperatures for optimal performance at body temperature.

- Smooth Surface Finish: Electropolished options reduce friction and improve device deployment.

These features make our superelastic nitinol tubing a superior choice over conventional materials for high-reliability medical applications.

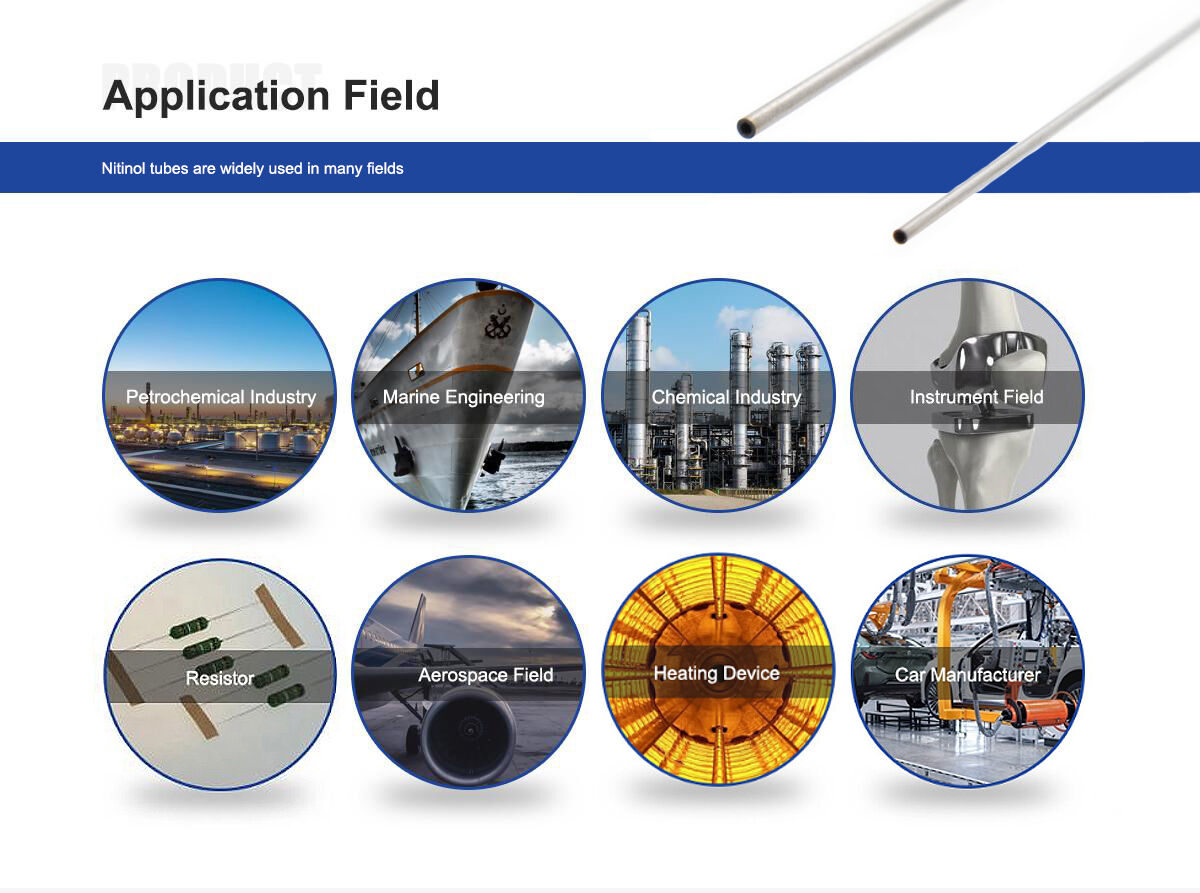

Applications of Medical Grade Nitinol Precision Hypotube

Our shape memory nitinol tube is widely utilized across interventional and implantable medical devices, leveraging its superelastic NiTi properties for enhanced performance:

- Catheters and Delivery Systems: Provides flexible, kink-resistant shafts for peripheral, coronary, and neurovascular catheters.

- Self-Expanding Stents: Forms the backbone of vascular and non-vascular stents that deploy reliably using shape memory.

- Guidewires and Needles: Enables precise navigation in endovascular procedures with superior torque and flexibility.

- Orthopedic and Endoscopic Instruments: Supports minimally invasive tools requiring high elasticity and biocompatibility.

- Heart Valves and Filters: Used in implantable devices like vena cava filters for long-term durability.

- Neurovascular and Urological Devices: Ideal for intricate pathways in brain and urinary tract interventions.

1.What is nitinol and why is it used in endoscopic instruments?

Nitinol (nickel-titanium alloy) is prized for its superelasticity and shape memory properties, allowing nitinol tubes to bend extensively without kinking and recover shape instantly—essential for flexible, reliable endoscopic medical devices.

2.Is medical nitinol tube biocompatible?

Yes, our medical-grade nitinol tubing features excellent biocompatibility due to its protective titanium oxide layer, making it safe for implants and long-term contact in minimally invasive procedures (compliant with biocompatibility standards like ISO 10993).

3.What makes this nitinol tube superelastic?

Superelasticity occurs above the austenite finish temperature, enabling up to 8-11% recoverable strain—far superior to stainless steel—ideal for kink-resistant performance in endoscopic hypotubes.

4.Can nitinol tubes be customized for specific endoscopic applications?

Absolutely. We offer customizable dimensions, Af temperatures, surface finishes, and laser-cut patterns for tailored high-precision nitinol tubing in catheters, guidewires, and surgical instruments.

5.How durable are superelastic nitinol tubes in repeated use?

Highly durable with exceptional fatigue resistance, our nitinol hypotubes withstand millions of cycles, supporting reusable endoscopic instruments without loss of performance.